A kind of flexible protective material and preparation method thereof

A technology of flexible protection and protective materials, applied in the direction of protective equipment, personnel protection equipment, offensive equipment, etc., can solve the problems of the influence of material flexibility, reduce wearing comfort, etc., and achieve improved flexibility, excellent anti-stab and anti-ballistic performance, and low cost low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

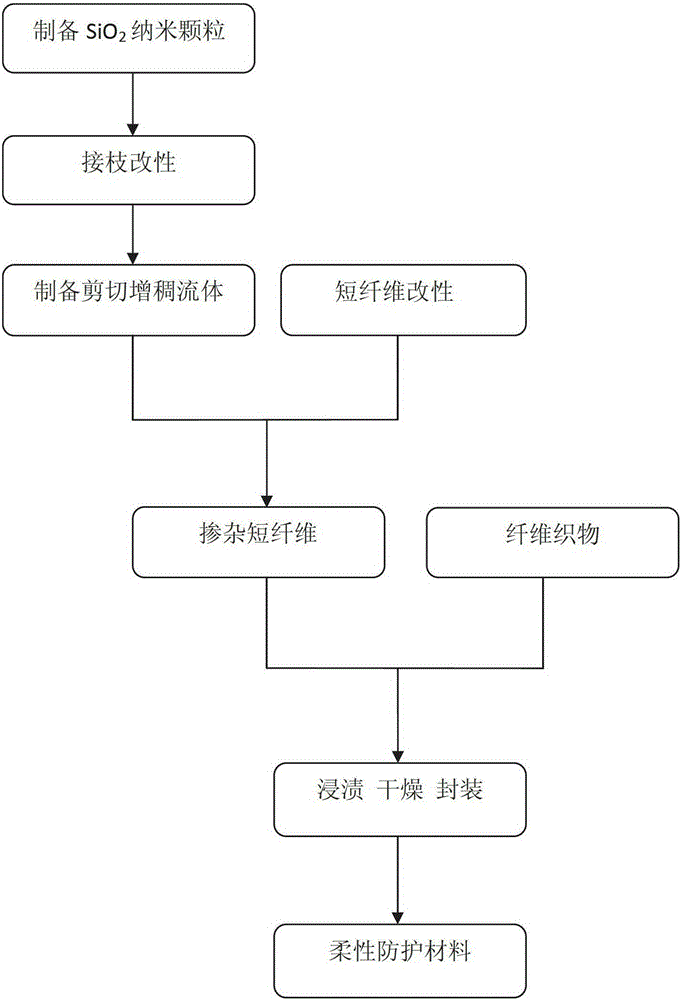

Method used

Image

Examples

preparation example Construction

[0028] SiO 2 Preparation of Nanoparticles: Preparation of Nano-SiO by Stober Method 2 According to the volume ratio of 1:2:2, configure the mixed solution of tetraethyl orthosilicate, absolute ethanol, and deionized water, put it into the reactor, and stir it evenly in a constant temperature water bath at 70°C, and then add it drop by drop Appropriate amount of ammonia water, adjust the pH to 9, so that the two solutions are fully mixed and reacted in the reactor to obtain a suspension of silica nanospheres, the suspension is cooled, washed by centrifugation, and placed in a vacuum drying oven at 80°C The solvent is removed by drying, and finally the obtained product is calcined in a resistance furnace for 1-2 hours.

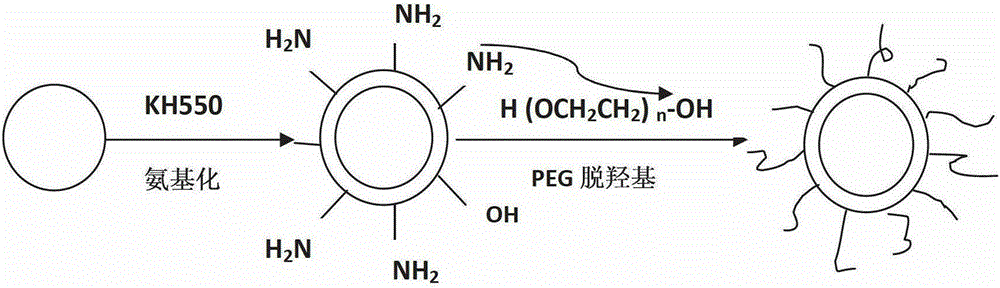

[0029] SiO 2 Nanoparticle surface graft modification: mix 95% volume fraction of absolute ethanol and 5% deionized water, add 2% volume fraction of KH550 surfactant, react for 5-10min to promote hydrolysis and form hydroxyl groups, and prepare by adding Monod...

Embodiment 1

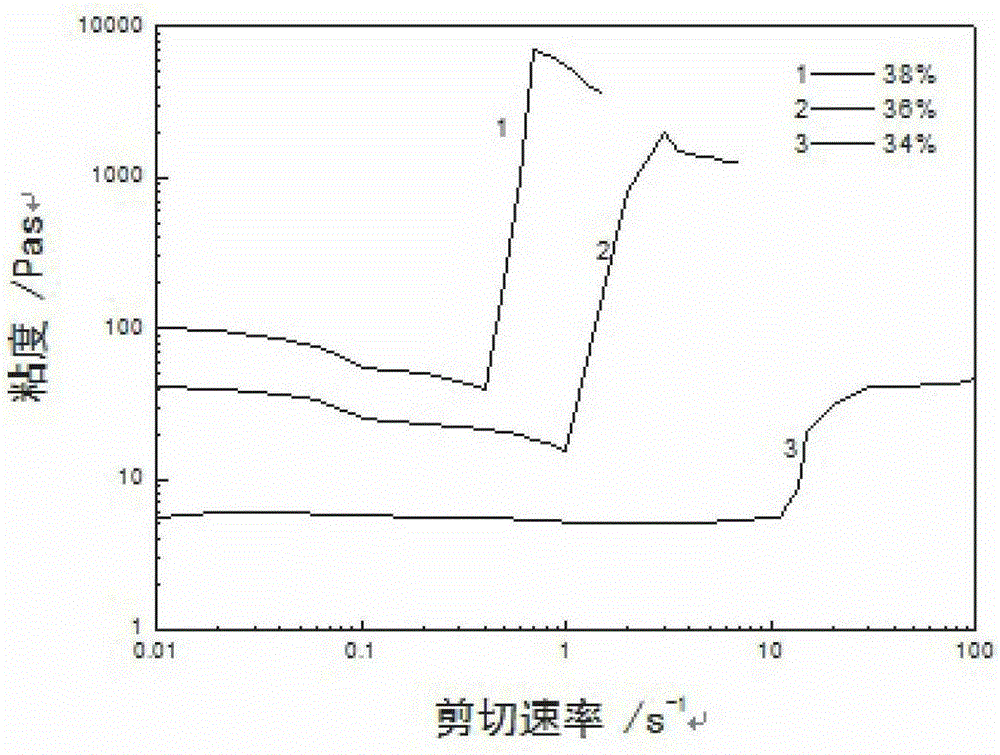

[0032] Fix the container containing PEG200 on a micro-vortex mixer, gradually add 30% mass fraction, the average particle size is about 500nm, and SiO2 modified by surface grafting during the vibration stirring process. 2 nanoparticles, shake and stir for 2-3h to make SiO 2 Uniformly dispersed in the dispersion medium PEG200 to form a shear thickening fluid. In order to ensure sufficient dispersion, SiO 2 After the nanoparticles are completely added, carry out 2-3h low-temperature ultrasonic dispersion. In order to ensure the stability of the STF dispersion system, vacuum dry the prepared STF for about 24 hours to remove air bubbles.

[0033] Fix the container with the prepared STF on a micro-vortex mixer, gradually add 10% mass fraction (the mass percentage of short carbon fibers and STF is 10%), and modify the modified STF with a length of about 0.2 mm during the vibration stirring process. Short carbon fiber, vibrate and stir for 2-3h. Vacuum dry for about 24 hours to r...

Embodiment 2

[0036] Fix the container containing PEG200 on a micro-vortex mixer, and gradually add SiO with a mass fraction of 30% and an average particle size of about 600 nm during the vibration and stirring process without surface graft modification. 2 nanoparticles, shake and stir for 2-3h to make SiO 2 Uniformly dispersed in the dispersion medium PEG200 to form a shear thickening fluid. In order to ensure sufficient dispersion, SiO 2 After the nanoparticles are completely added, carry out 2-3h low-temperature ultrasonic dispersion. In order to ensure the stability of the STF dispersion system, vacuum dry the prepared STF for about 24 hours to remove air bubbles.

[0037] The container that the prepared STF is housed is fixed on the miniature vortex mixer, and the mass fraction 10% (the mass percentage of glass short fiber and STF is 10%), the length after the modification of about 0.5mm is gradually added in the vibration stirring process. Glass short fiber, vibrate and stir for 2-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com