Method for obtaining optimal dispatching scheme of part machining based on one-dimensional particle swarm algorithm

A particle swarm algorithm and part processing technology, which is applied in the directions of comprehensive factory control, digital control, electrical program control, etc., and can solve problems such as high algorithm complexity, low solution efficiency, and high programming difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

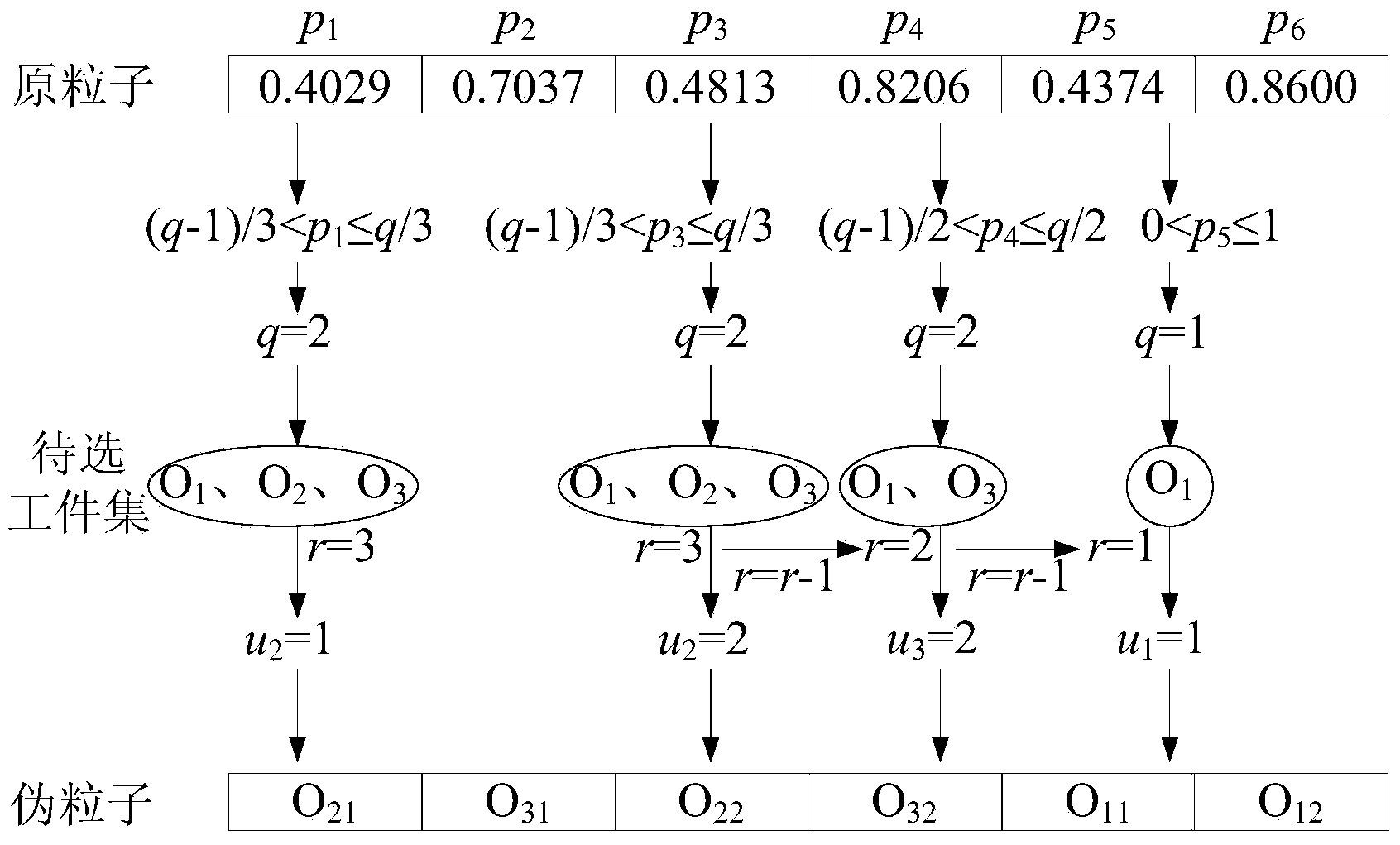

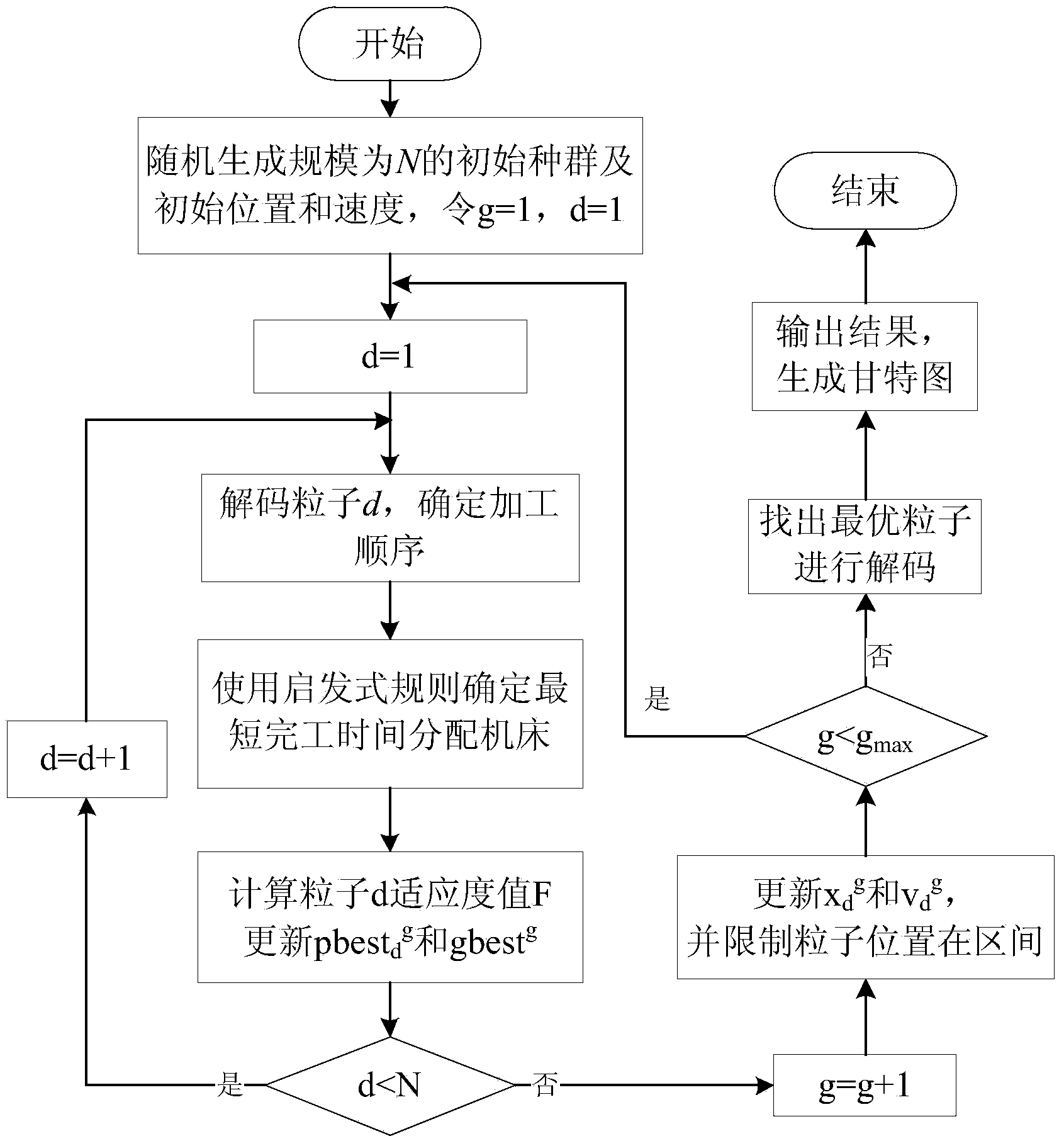

Method used

Image

Examples

Embodiment

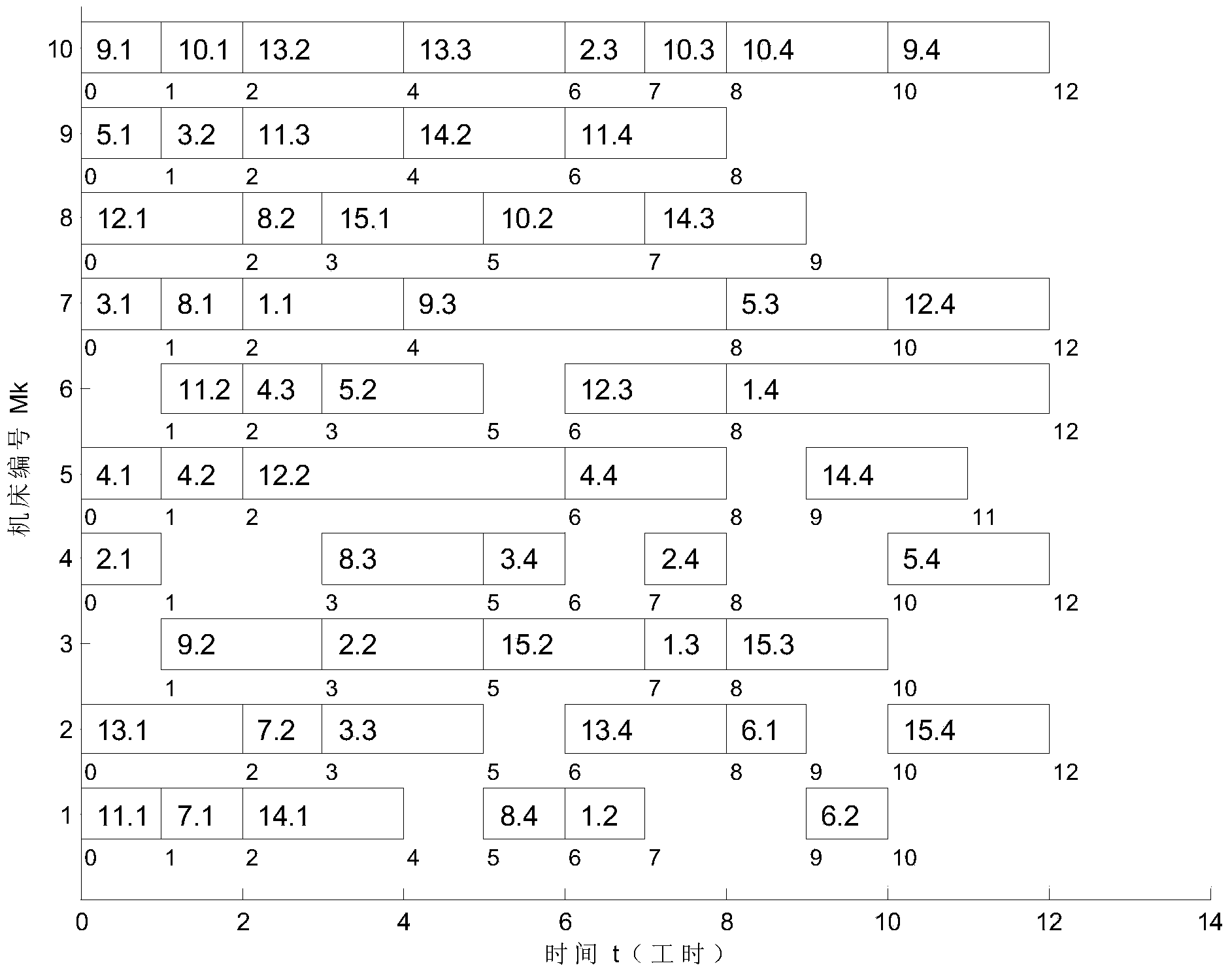

[0139] A flexible manufacturing workshop undertakes the processing tasks of 15 kinds of workpieces. The workshop has 10 flexible machine tools. The processing time of the machine tools for each process is shown in Table 1.

[0140] Table 115×10 scale flexible workshop scheduling example data table (t ijk Unit: minute)

[0141]

[0142]

[0143]

[0144] First, establish the objective function F of this problem. In the production process, the core goal is generally to shorten the manufacturing cycle, and the secondary goal is to reduce the load of the machine tool, so the weight coefficient w of the comprehensive optimization goal can be set 1 =0.55, w 2 =0.25,w 3 =0.2 (It can also be set according to the user's solution intention, as long as w 1 +w 2 +w 3 =1).

[0145] F = 0.55 × max 1 ≤ k ≤ 10 { ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com