Write element, thermally assisted magnetic head slider, magnetic head flap assembly and manufacturing method

A technology that assists magnetic heads and manufacturing methods, and is applied in the manufacture of record carriers, the hydrodynamic spacing of heads, and the alignment of head racks, and can solve problems such as high temperature and impact on the surface of magnetic recording media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] Several different preferred embodiments of the present invention will now be described with reference to the accompanying drawings, wherein like reference numerals in different drawings represent like parts. As mentioned above, the essence of the present invention lies in a manufacturing method of a writing element, a thermally assisted magnetic head slider, HGA, HDD and a thermally assisted magnetic head slider, so as to improve the performance of the thermally assisted magnetic head slider, and ultimately enhance the structure and performance of the HDD .

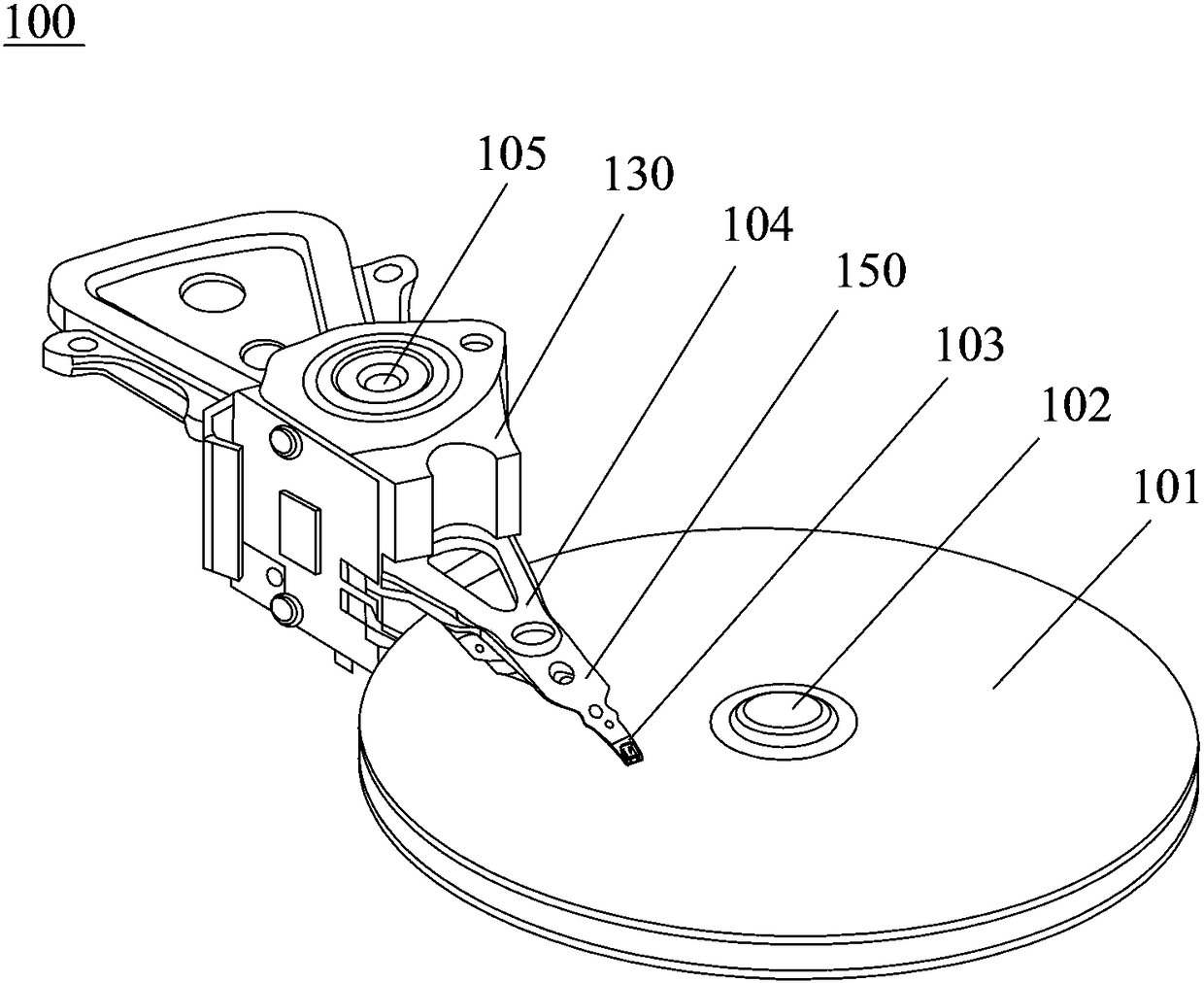

[0087] figure 2 It is a perspective view of an embodiment of the HDD of the present invention. The HDD 300 includes an HGA 200 , a driving arm 304 connected to the HGA 200 , a series of rotating disks 301 , and a spindle motor 302 for driving the disks 301 , all of which are installed in a casing 309 . The structure of the HDD 300 of the present invention is not limited thereto, for example, the number of the ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com