Two-dimensional nanocrystalline metal oxide composite coating lithium manganate positive electrode material and preparation method thereof

A coating lithium manganate, two-dimensional nanotechnology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of not being able to meet high ionic conductivity and electronic conductivity at the same time, Achieve uniform thickness, obvious effect and uniform dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Weigh 0.3g of lanthanum nitrate hexahydrate and place it in a 250mL three-necked flask, add an appropriate amount of deionized water to dissolve, and obtain a lanthanum salt solution;

[0038] 2) Weighing 30g of spinel-type lithium manganate positive electrode material, adding it to the lanthanum salt solution, and performing ultrasonic treatment for 3 hours under the condition of 100W / 40KHz to obtain mixed solution A;

[0039] 3) Under ultrasonic conditions of 100W / 40KHz, add ammonia water to the mixed solution A until the pH of the mixed solution A is 9;

[0040] 4) Put the solution obtained in step 3) in a 500mL reaction kettle, and react at 180°C for 12h; take it out, cool at room temperature, filter, wash with deionized water, and dry to obtain a spinel-type lithium manganate material coated with lanthanum salt Precursor;

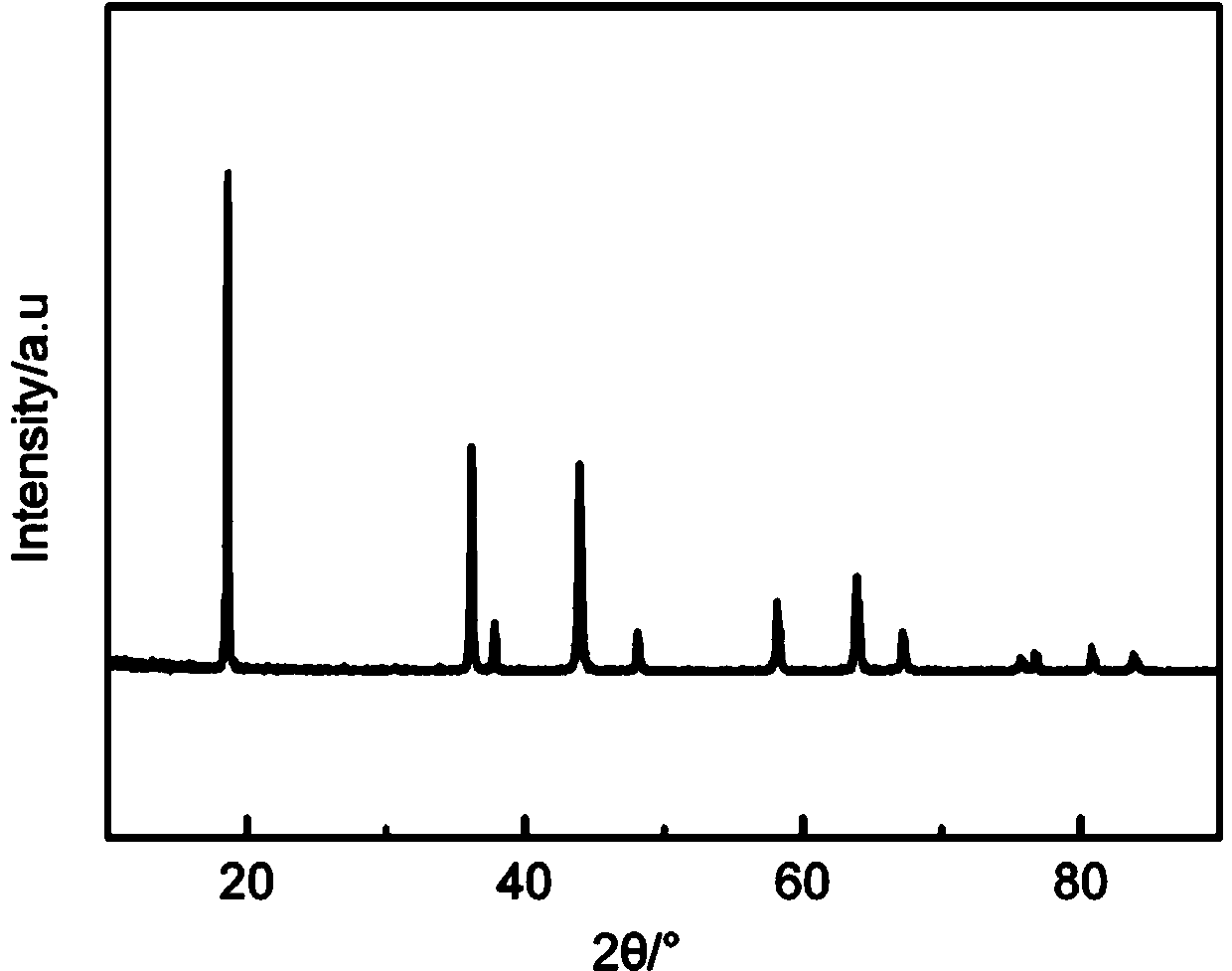

[0041] 5) placing the precursor of the lanthanum salt-coated spinel-type lithium manganate material at 500° C., and heat-treating it for 5 ...

Embodiment 2

[0052] 1) Weigh 1.5g of lanthanum nitrate hexahydrate and place it in a 250mL three-necked flask, add an appropriate amount of deionized water to dissolve, and obtain a lanthanum salt solution;

[0053] 2) Weigh 30g of spinel-type lithium manganate cathode material, add it into a three-necked flask, and perform ultrasonic treatment at 75°C, 500W / 60KHz for 1 hour to obtain a mixed solution A;

[0054] 3) Under ultrasonic conditions of 500W / 60KHz, add urea aqueous solution to the mixed solution A until the pH of the mixed solution A is 8;

[0055] 4) Put the solution obtained in step 3) in a 500mL reaction kettle, and react at 180°C for 6h; take it out, cool at room temperature, filter, wash with deionized water, and dry to obtain a spinel-type lithium manganate material coated with lanthanum salt the precursor of

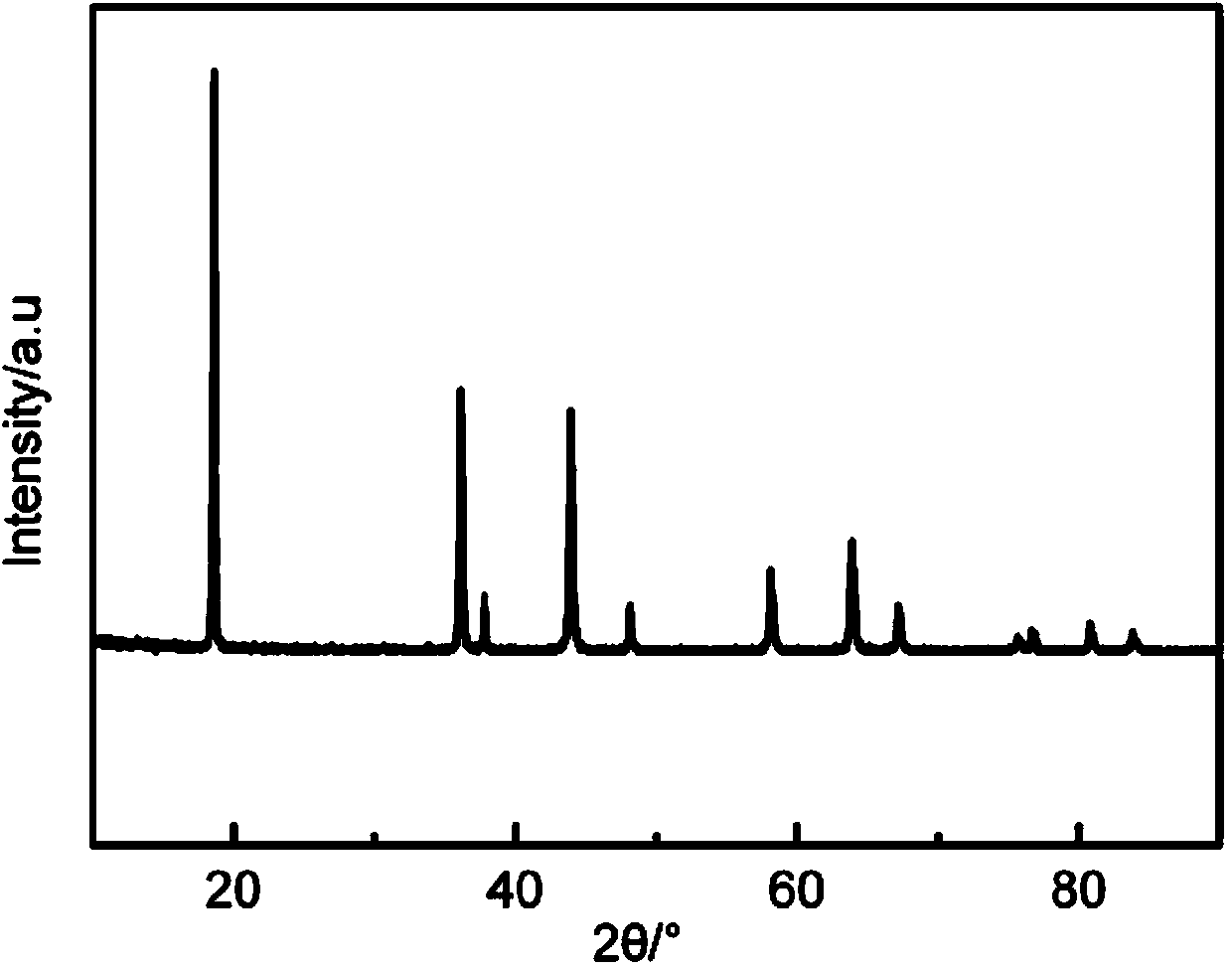

[0056] 5) placing the obtained precursor of the lanthanum salt-coated spinel-type lithium manganate material at 400° C., and heat-treating it for 6 hours to obtain ...

Embodiment 3

[0064] 1) Weigh 0.60g of lanthanum chloride and place it in a 250mL three-necked flask, add an appropriate amount of deionized water to dissolve, and obtain a lanthanum salt solution;

[0065] 2) Weigh 30g of spinel-type lithium manganate cathode material, add it into a three-necked flask, and perform ultrasonic treatment at 75°C and 300W / 50KHz for 2 hours to obtain a mixed solution A;

[0066] 3) Under the ultrasonic condition of 300W / 50KHz, add the mixed solution A of ammonia water and urea to the mixed solution until the pH of the mixed solution A is 9;

[0067] 4) Put the solution obtained in 3) in a 500mL reaction kettle, and react at 180°C for 12h; take it out, cool at room temperature, filter, wash with deionized water, and dry to obtain the lanthanum salt-coated spinel lithium manganate material. Precursor;

[0068]5) placing the obtained precursor of the lanthanum salt-coated spinel-type lithium manganate material at 600° C., and heat-treating it for 4 hours to obtai...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap