Lithium ion battery negative electrode material and preparing method thereof

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low initial charge and discharge efficiency, poor cycle performance, etc., and achieve low cost of raw materials, high discharge efficiency, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

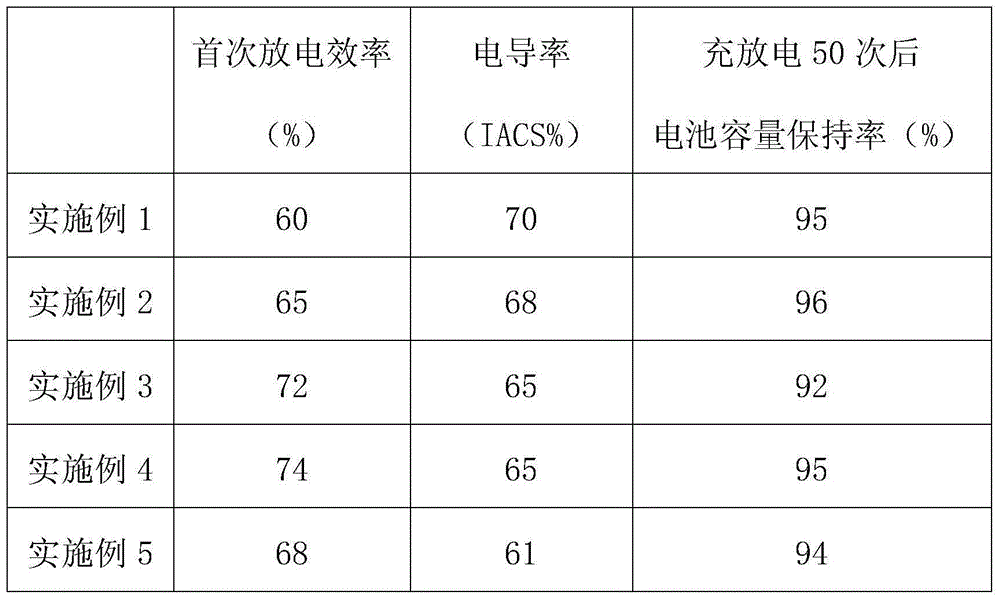

Examples

Embodiment 1

[0033] Example 1 The organosilicon waste contact body in this example includes porous silicon, carbon and copper; the carbon material matrix includes carbon fibers, graphite balls and graphene; the preparation of silicon-carbon composite materials is based on methane and propylene as raw materials, Cracking under the condition of 1MPa for 10h to obtain carbon particles, and then compound modification with silicon, the solvent used for compound modification is a mixed solvent of methyl ethyl ether, xylene and water, the bath ratio of the modification reaction is 1:15; finally The silicon-carbon composite material and organic silicon waste contacts are vapor-deposited on the carbon material substrate. The protective atmosphere of the vapor-phase deposition is nitrogen, the vapor-phase deposition time is 4h, the temperature is 1000°C, and the air pressure is 2MPa.

Embodiment 2

[0035] The organosilicon waste contact body of this embodiment includes porous silicon and copper; the carbon material matrix includes carbon fibers, carbon nanotubes, graphite balls and natural graphite; Cracking under conditions for 24 hours to obtain carbon particles, and then obtained through composite modification with silicon, the solvent used for composite modification is a mixed solvent of chloroform and water, and the bath ratio of the modification reaction is 1:60; finally, the silicon-carbon composite material and The organic silicon waste contacts were vapor-deposited on the carbon material substrate. The protective atmosphere of the vapor-phase deposition was nitrogen, helium and neon. The vapor-phase deposition time was 0.5h, the temperature was 900°C, and the pressure was 1MPa.

Embodiment 3

[0037] The organosilicon waste contact body of this embodiment includes porous silicon and carbon; the carbon material matrix includes carbon fiber, carbon fiber and graphene; the preparation of silicon carbon composite material is to use propane and ethylene as raw material, at 1150 ℃, cracking 1.5 under the condition of 1.5MPa h obtained carbon particles, and then obtained through composite modification with silicon, the solvent used for composite modification is a mixed solvent of methyl ethyl ether, toluene and acetone, and the bath ratio of the modification reaction is 1:37; finally, the silicon-carbon composite material and The waste organosilicon contacts were vapor-deposited on the carbon material substrate. The protective atmosphere of the vapor-phase deposition was nitrogen and argon. The vapor-phase deposition time was 3 hours, the temperature was 750°C, and the pressure was 1.2MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| discharge efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com