Silicon-carbon negative electrode material and preparation method thereof

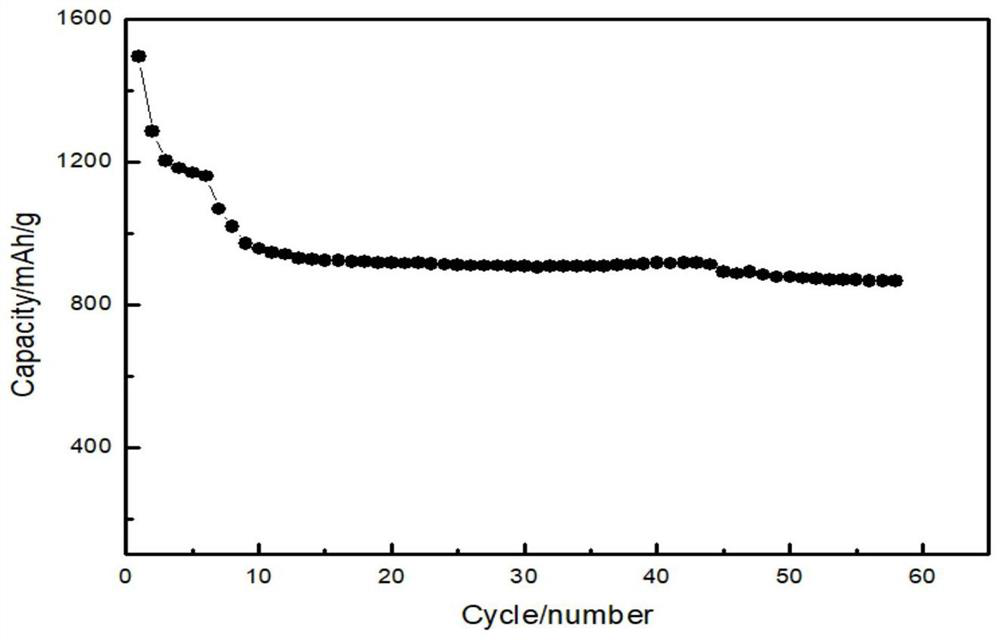

A negative electrode material, silicon carbon technology, applied in the field of silicon carbon negative electrode material and its preparation, can solve the problems of difficult long-term storage, easy emulsification, easy agglomeration, etc., and achieve the effects of stable capacity, smooth surface and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

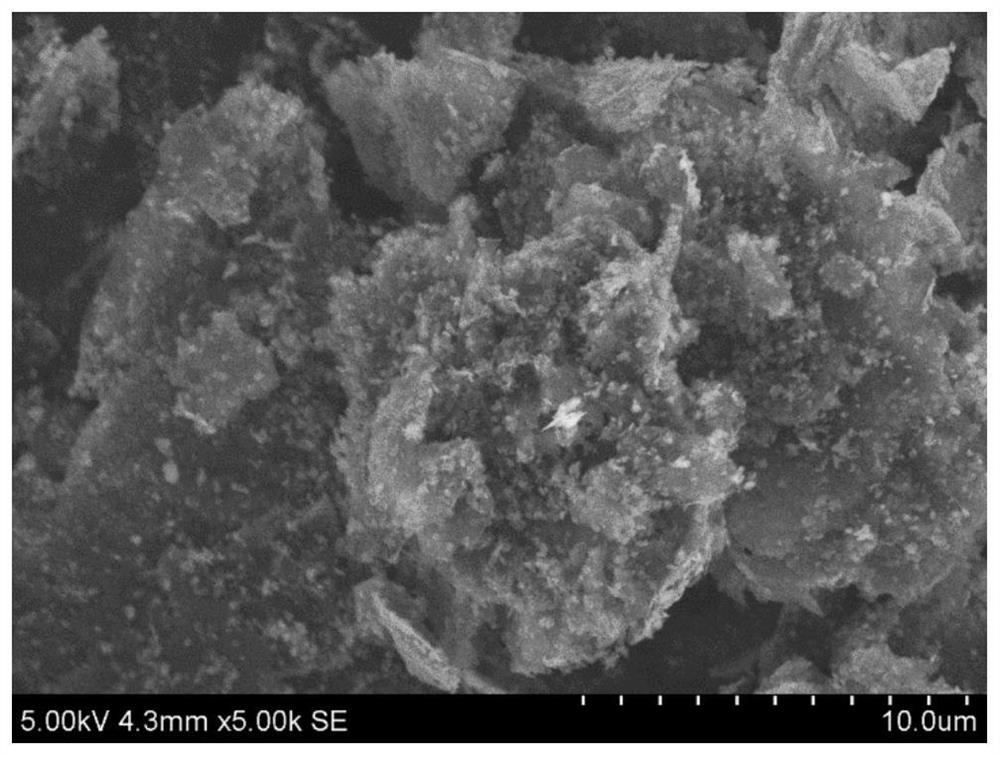

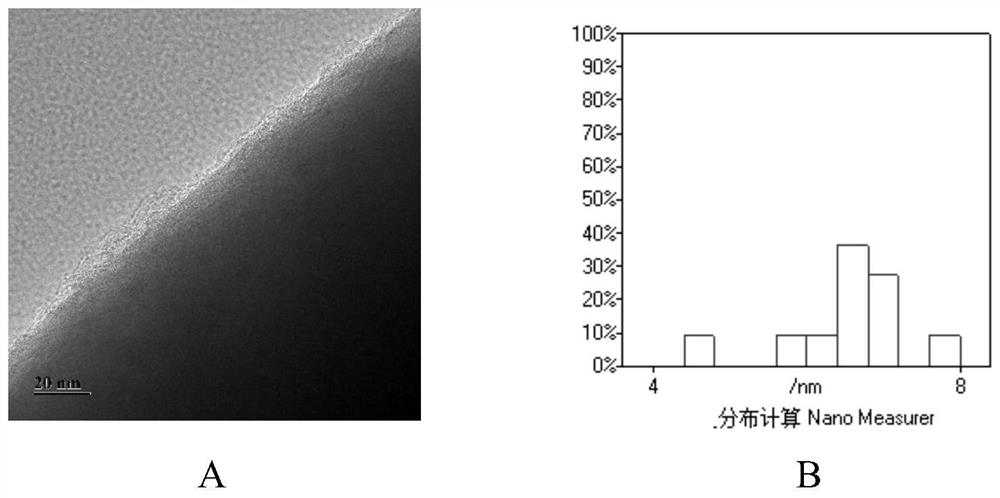

[0054] (1) Crushing silicon powder with a particle size of 3-5um with a jet crusher until the particle size D50 is 50nm;

[0055] (2) Add 10 g of crushed nano-silicon powder into 40 g of isopropanol, then add it to a high-speed disperser, and disperse for 5 hours at a speed of 1500 r / min to obtain a silicon dispersion with a solid content of 20%;

[0056] (3) Weigh 1 g of carboxymethyl cellulose and 2 g of starch, slowly add them to the silicon dispersion under stirring conditions, and disperse at a speed of 1800 r / min for 1.5 hours to obtain solution A;

[0057] (4) Stir and evaporate the solution A to dryness, raise the temperature to 550° C. at a temperature rise rate of 5° C. / min under a nitrogen atmosphere, and roast for 3 hours to obtain a silicon precursor;

[0058] (5) Add 4.5g of artificial graphite, 0.7g of pitch and 3.5g of silicon precursor to 35g of deionized water for high-speed mixing, and disperse at a speed of 1500r / min for 3 hours to obtain solution B;

[00...

Embodiment 2

[0061] (1) Crushing silicon powder with a particle size of 3-5um with a jet crusher until the particle size D50 is 80nm;

[0062] (2) Add 10 g of crushed nano-silicon powder into 40 g of ethanol, then add it to a high-speed disperser, and disperse for 3 hours at a speed of 1500 r / min to obtain a silicon dispersion with a solid content of 18%;

[0063] (3) Weigh 1 g of glucose and 2 g of starch, slowly add them into the silicon dispersion under stirring conditions, and disperse at a speed of 1800 r / min for 1.5 hours to obtain solution A;

[0064] (4) Stir and evaporate the solution A to dryness, raise the temperature to 550° C. at a temperature rise rate of 5° C. / min under a nitrogen atmosphere, and roast for 3 hours to obtain a silicon precursor;

[0065] (5) Add 4.5g of artificial graphite, 0.7g of pitch and 3.5g of silicon precursor to 35g of deionized water for high-speed mixing, and disperse at a speed of 1500r / min for 3 hours to obtain solution B;

[0066] (6) The soluti...

Embodiment 3

[0068] (1) Crushing silicon powder with a particle size of 3-5um with a jet crusher until the particle size is 100nm;

[0069] (2) Add 10 g of crushed nano-silicon powder into 40 g of ethanol, and disperse for 6 hours at a speed of 1500 r / min with a high-speed disperser to obtain a silicon dispersion with a solid content of 16%;

[0070] (3) Weigh 1 g of polycondensate and 2 g of starch, slowly add them into the silicon dispersion under stirring conditions, and disperse at a speed of 1800 r / min for 1.5 hours to obtain solution A;

[0071] (4) Stir and evaporate the solution A to dryness, raise the temperature to 550° C. at a temperature rise rate of 5° C. / min under a nitrogen atmosphere, and roast for 3 hours to obtain a silicon precursor;

[0072] (5) Add 4.5g of artificial graphite, 0.7g of pitch and 3.5g of silicon precursor to 35g of deionized water for high-speed mixing, and disperse at a speed of 1500r / min for 3 hours to obtain solution B;

[0073] (6) The solution B wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com