A kind of lithium ion battery negative electrode active material and preparation method, negative electrode and lithium ion battery

A negative electrode active material and lithium-ion battery technology, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problems of poor battery cycle performance and large differences in conductivity of silicon-carbon materials, etc. Achieve better capacity, high first discharge efficiency, and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention has no special requirements for the preparation method of the negative electrode of the lithium ion battery, and can be carried out with reference to the prior art. For example, the preparation method of the negative electrode provided by the present invention generally includes coating and / or filling the negative electrode slurry on the negative electrode conductive matrix On, dry, calendered or not.

[0039] The negative electrode conductive substrate can be a conventional negative electrode conductive substrate in a lithium ion battery, such as punched metal, metal foil, mesh metal, foam metal, copper foil is used as the negative electrode conductive substrate in a specific embodiment of the present invention.

[0040] The methods and conditions of coating and / or filling, drying and calendering are well known to those skilled in the art. For example, the drying temperature is generally 100-150°C.

[0041] The present invention also provides a l...

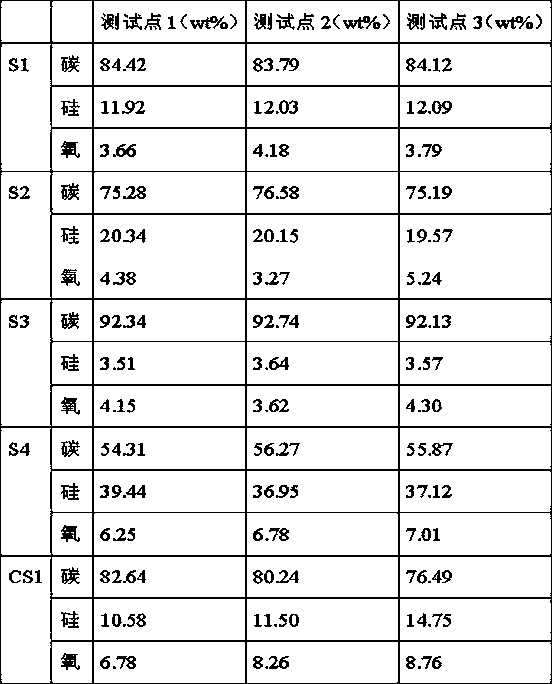

Embodiment 1

[0053] Mix 1g of silicon with a particle size of 30nm and 10ml of diethylene glycol, then high-energy ball mill at a speed of 1000 rpm for 90 minutes to obtain A1; 10g of flat natural graphite at a speed of 1500 rpm for high-energy ball milling for 90 minutes Obtain flake graphite; then add the flake graphite into A1 and continue high-energy ball milling for 90 minutes at a rotational speed of 1500 rpm. Then under the protection of high-purity Ar, the temperature was raised to 950°C at a heating rate of 10°C / min, and calcined at 950°C for 5 hours to obtain product B1, which was crushed, treated with 3% HF for 20 minutes, and then washed with water until The pH value is 6, after drying, mix with 0.2g of high-temperature pitch (40), add 20g of naphthalene: stir at 80°C for 60 minutes, then put the stirred product under the protection of high-purity Ar, and increase the temperature to 10°C The temperature was raised to 1000° C. at a heating rate of 1 / min, and then calcined for 3 ...

Embodiment 2

[0055] Mix 2g of silicon with a particle size of 100nm and 10ml of diethylene glycol, and then high-energy ball mill at a speed of 2000 rpm for 60 minutes to obtain A2; 10g of Betray 918 graphite is high-energy ball milled at a speed of 2000 rpm 30min to obtain flake graphite; then add the flake graphite to A2 and continue high-energy ball milling at a speed of 1500 rpm for 90min. then 5%H 2 Under the protection of / Ar mixed gas, the temperature was raised to 600°C at a heating rate of 20°C / min, and calcined at 600°C for 3 hours to obtain product B2, which was crushed, treated with 15% NaOH aqueous solution for 30min, and then washed to pH The value is 8, and after drying, mix with 6g phenolic resin and stir at 60°C for 90 minutes, then put the stirred product in 5%H 2 Under the protection of / Ar mixed gas, the temperature was raised to 950° C. at a heating rate of 20° C. / min, and then calcined for 5 hours to obtain the negative electrode active material S2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com