A kind of electrolytic solution, preparation and application of stabilizing silicon carbon surface of lithium ion battery

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve problems such as battery flatulence and affecting battery safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

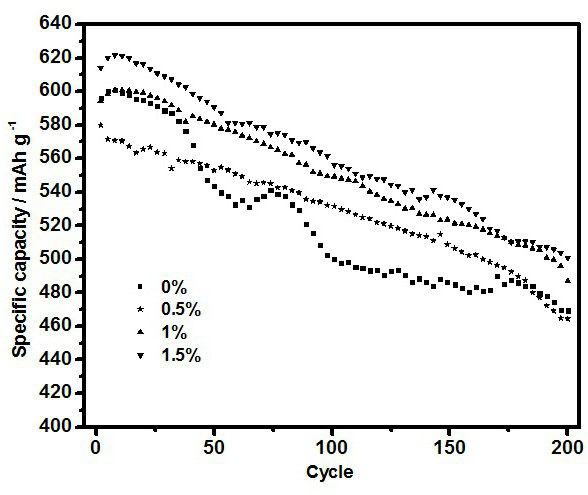

[0033] An electrolyte for stabilizing the silicon carbon surface of a lithium ion battery, comprising the following raw materials: 90 g of ethylene carbonate, 60 g of diethyl carbonate, 120 g of dimethyl carbonate, 30 g of fluoroethylene carbonate, and 39.6 g of lithium hexafluorophosphate .

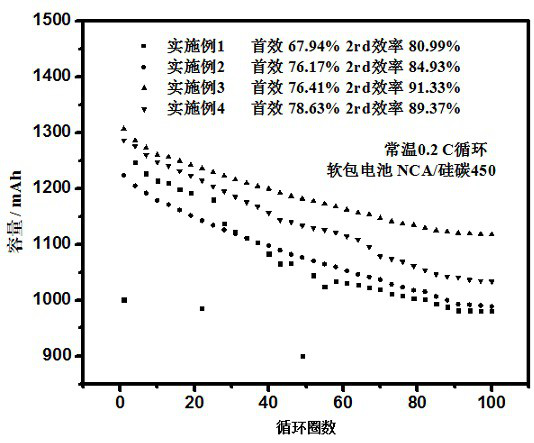

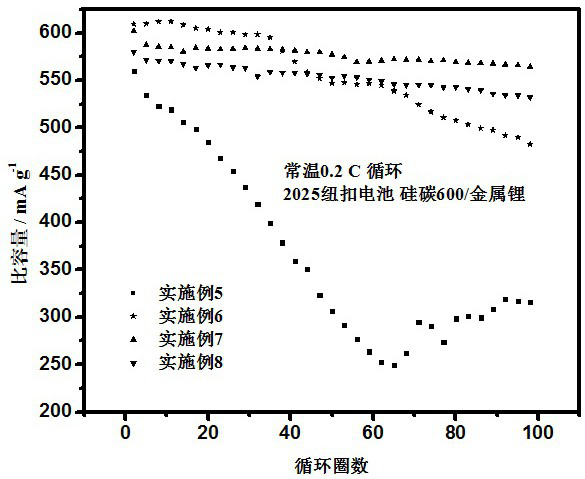

[0034] The battery system is a 2025 button battery, silicon carbon (capacity 600 mAh g -1 ) / metal lithium; soft pack battery, lithium nickel cobalt aluminate / silicon carbon (capacity 450 mAh g -1 ).

[0035] As a film-forming additive, fluoroethylene carbonate can form an effective solid-state electrolyte film on the surface of the electrode, and the battery capacity fluctuates significantly during the cycle of the button and pouch batteries. This is due to the poor compactness and uniformity of the SEI film, and the cycle process The middle SEI film is ruptured, resulting in the co-intercalation and reduction of the electrolyte solvent to form a new SEI film.

Embodiment 2

[0037] An electrolyte for stabilizing the silicon carbon surface of a lithium ion battery, comprising the following raw materials: 90 g of ethylene carbonate, 60 g of diethyl carbonate, 120 g of dimethyl carbonate, 30 g of fluoroethylene carbonate, dimethyl carbonate Dimethoxysilane 1.6 g, lithium hexafluorophosphate 39.6 g, battery system is 2025 button cell, silicon carbon (capacity 600 mAh g -1 ) / metal lithium; soft pack battery, lithium nickel cobalt aluminate / silicon carbon (capacity 450 mAh g -1 ).

[0038] When 0.5% dimethoxydimethylsilane was used as a coating additive, the cycle stability of the battery was significantly enhanced compared with Example 1, and there was no fluctuation during the cycle. Compared with Example 1, the first charge-discharge efficiency and the second charge-discharge efficiency during the formation of the full battery of the soft pack are significantly improved.

Embodiment 3

[0040] An electrolyte for stabilizing the silicon carbon surface of a lithium-ion battery, comprising the following raw materials: 90 g of ethylene carbonate, 60 g of diethyl carbonate, 120 g of dimethyl carbonate, 30 g of fluoroethylene carbonate, dimethyl carbonate 3.2 g of dimethoxysilane and 39.6 g of lithium hexafluorophosphate. The battery system is 2025 button battery, silicon carbon 600 / metal lithium; soft pack battery, nickel cobalt aluminate / silicon carbon (capacity 450 mAh g -1 ).

[0041]When 1% dimethyldimethoxysilane is used as an additive, the battery cycle process has a stable capacity without fluctuation, and the capacity retention rate is improved compared with Example 1. The initial charge and discharge efficiency of the pouch battery is higher than that of Examples 1 and 2. After cycling, the electrode sheet is less wrinkled and the interface is stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com