Lead storage battery production method, lead storage battery, electrolyte production method and electrolyte

A production method and technology of lead-acid batteries, applied in the field of electrolyte, can solve the problems that the utilization rate cannot be further improved, and it is difficult to play a large role.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

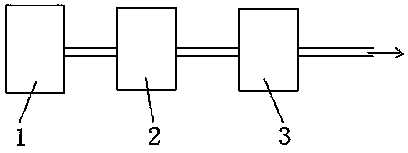

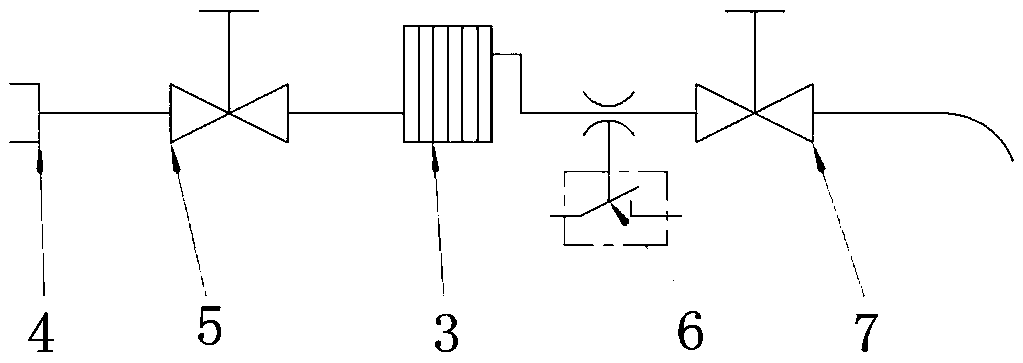

[0026] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0027] The specific embodiment of the first kind of lead-acid battery production method of the present invention comprises the electrolyte production process, in the electrolyte production process, after the distilled water that composes electrolyte is processed into the distilled water of small molecule group by electrochemical water equipment, then with pure Sulfuric acid mixing, wherein the electrochemical water equipment adopts the electrochemical water equipment that can make distilled water into distilled water of small molecular clusters with a molecular cluster number of not more than 9, so that small molecular cluster water with a molecular cluster number of not more than 9 is used in the electrolyte.

[0028] At present, the distilled water used in the industrial production of electrolyte is basically a water body of macromolecular clusters, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com