Cavity filter and screw device

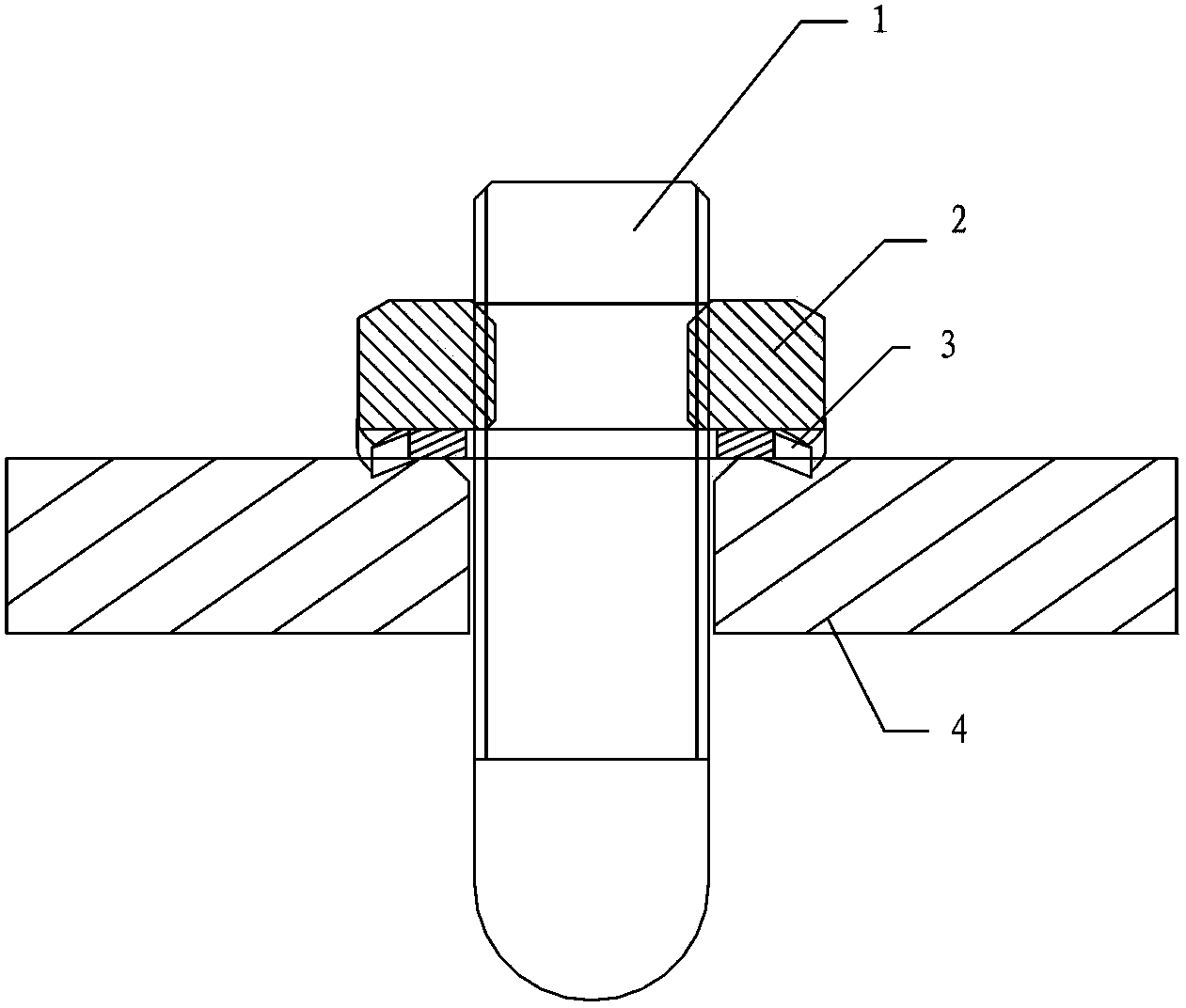

A cavity filter and cavity technology, applied in the field of communication, can solve the problems of large space occupied by nut 2 and shrapnel 3, many matching parts, and time-consuming installation, so as to save external space, not easy to loosen, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

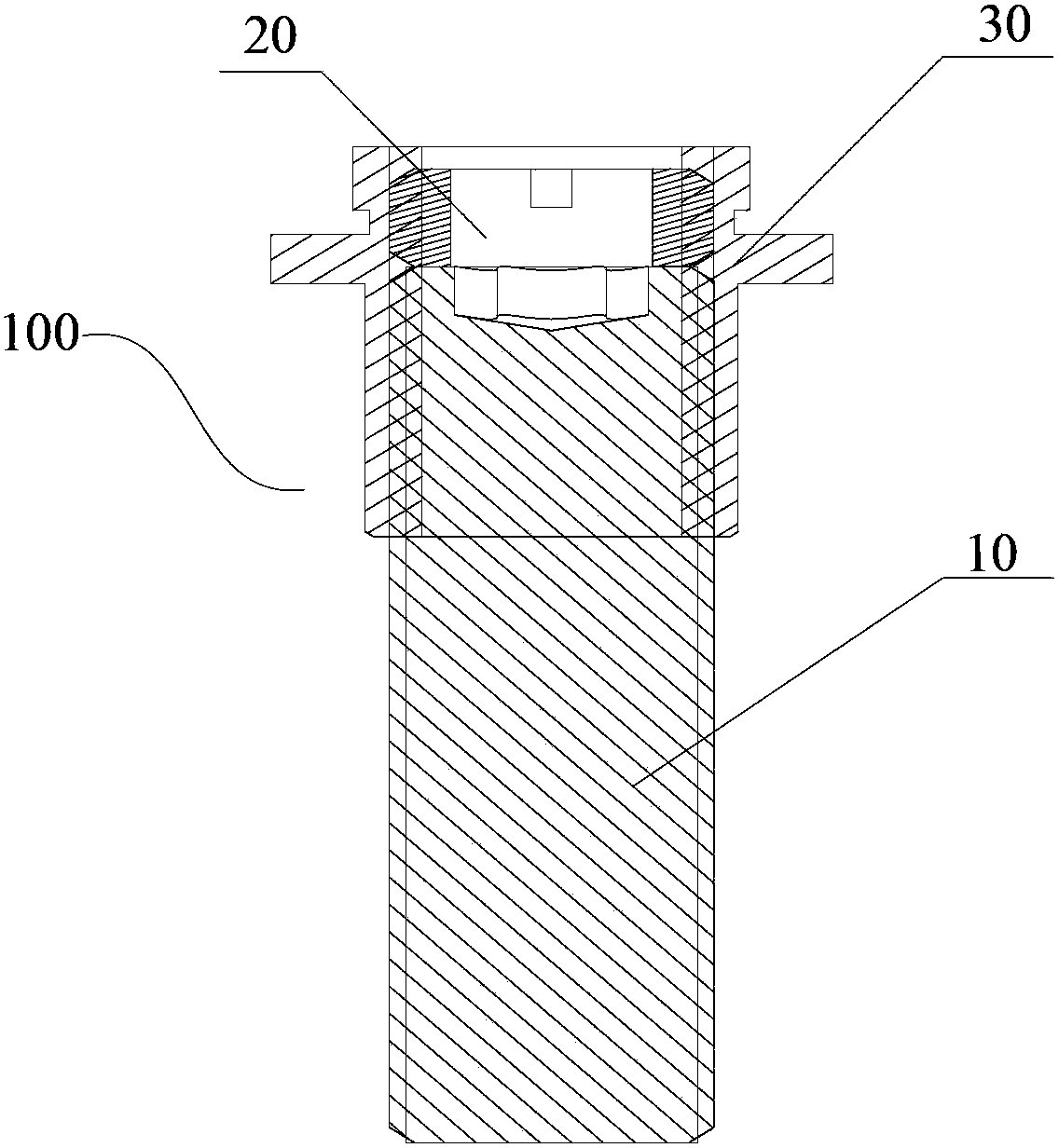

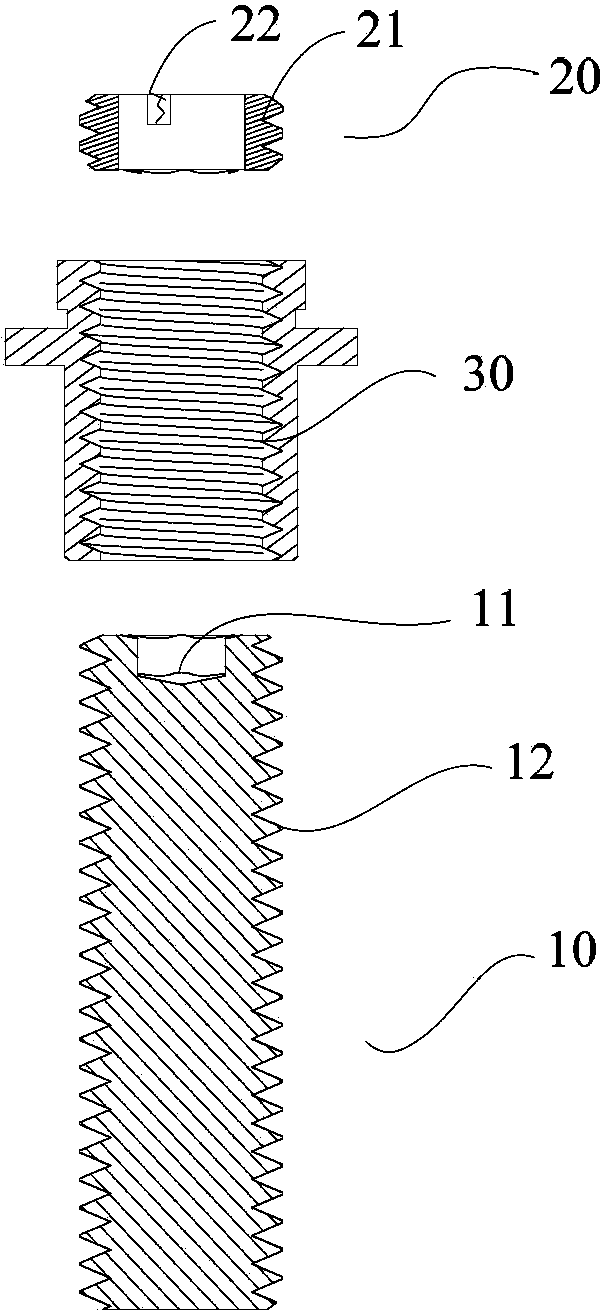

[0020] like figure 2 As shown, this embodiment provides a screw device 100, including a first screw 10 and a locking member 20 for locking the first screw 10, the first screw 10 and the locking member 20 are screwed together In the threaded hole 30, one end of the locking member 20 is docked with one end of the first screw rod 10 to generate a pre-tightening force to lock the first screw rod 10, and the other end surface of the locking member 20 does not protrude from the first screw rod 10. The above threaded hole 30.

[0021] Specifically, refer to image 3 and Figure 4 , The locking member 20 is preferably an annular body with an external thread 21, and the annular body is used to allow an external workpiece to pass through during installation to position the first screw rod. The end face of one end of the locking member is provided with a notch 22 for screwing the locking member into the threaded hole. The notch can be preferably two symmetrical notches, and certainly...

Embodiment 2

[0028] This embodiment provides a cavity filter 200, refer to Figure 5 , including a closed cavity 210 composed of at least one face, and a tuning screw device 100 assembled on at least one face, the tuning screw device can be referred to together figure 2 , image 3 and Figure 4 , the tuning screw device 100 includes a tuning screw 10 that is at least partially threaded with the cavity 210 and a locking member 20 for locking the tuning screw, the tuning screw 10 and the locking member 20 are both screwed In the threaded hole 30 on the cavity, one end of the locking member 20 is docked with one end of the tuning screw 10 to generate a pre-tightening force to lock the tuning screw 10, and the other end of the locking member 20 is not convex. out of the threaded hole 30 .

[0029] The tuning screw device 100 on the installation cavity 210 is used to adjust the radio frequency parameters in the filter cavity, and the radio frequency parameters are changed by adjusting the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com