water-swellable polymer beads

A water-swellable, polymer-based technology, applied in the field of polymer pellet preparation, can solve problems such as reduced compatibility

Inactive Publication Date: 2016-08-24

SAUDI BASIC IND CORP SA

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The problem with using emulsifiers with longer linear alkyl chains is that the compatibility of the tails of these aliphatic emulsifiers with the aromatic styrene / polystyrene phase decreases as the conversion of the styrene / polystyrene mixture increases

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-8

[0121]Examples 1-8 were carried out in the same manner as Example 9, except that the parameters were varied as described in Table 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

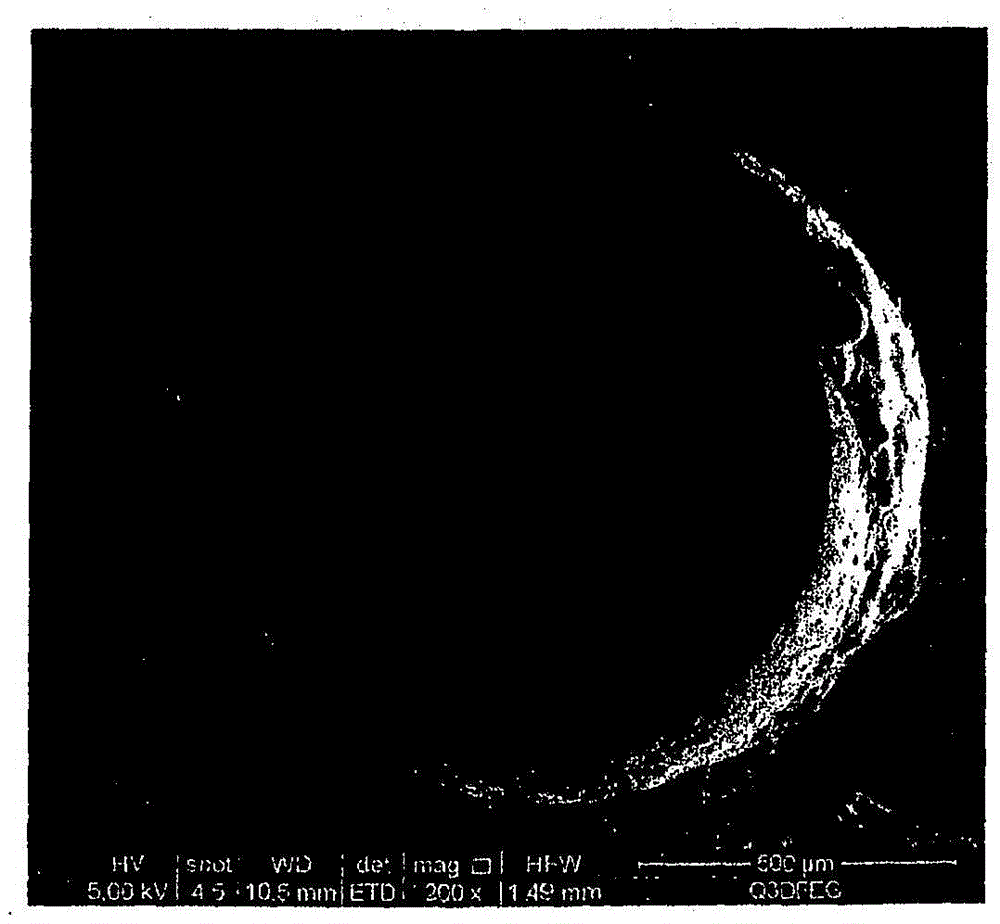

The present invention relates to a process for the emulsifier-free preparation of water-swellable polymer beads, said process comprising the steps of: a) providing an emulsifier-free starting composition comprising styrene and a polyphenylene ether resin, b) pre- polymerizing the starting composition to obtain a prepolymer composition, c) adding to the prepolymer composition an aqueous dispersion of nanoclay without modifiers to obtain an inverse emulsion, d) a suspending step in an aqueous medium c) the inverse emulsion obtained in step d) to produce an aqueous suspension of suspended droplets, and e) polymerizing the monomers in the droplets of the suspension obtained in step d) to obtain water-swellable polymer globules .

Description

technical field [0001] The present invention relates to a process for the preparation of water-swellable polymer beads (WEPS). Background technique [0002] Commercial expandable polystyrene pellets (EPS) usually use pentane as a blowing agent. Use pentane and its isomers to form low-density homogeneous EPS foam. But one major disadvantage of using pentane or its isomers is that it is harmful to the environment. Research has shown that both pentane and its isomers contribute to the formation of ozone in the lower atmosphere. In addition, carbon dioxide, which contributes to the greenhouse effect, is also formed during the photooxidation of pentane. [0003] The dissertation "WaterExpandablePolystyrene" by J.J.Crevecoeur of the University of Eindhoven in 1997 describes a process for the production of WEPS in which water finely dispersed in styrene is first emulsified by surface-active substances and the styrene is subsequently polymerized to a conversion of 50%. The mixtu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08J9/12C08J9/20C08L25/06C08K3/34C08L71/12

CPCC08J9/0061C08J9/008C08J9/20C08J2325/06C08J2471/12C08K3/346C08L25/06C08L71/12C08L25/14

Inventor G·加姆迪M·A·G·扬森L·N·I·H·内利森姆

Owner SAUDI BASIC IND CORP SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com