Nozzle structure for spraying device

A coating equipment, spraying equipment technology, applied in the direction of spraying device, electrostatic spraying device, etc., can solve the problems of low technical content, inability to move the nozzle, insufficient technical ability, etc., to achieve good operation stability, uniform powder, spray uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

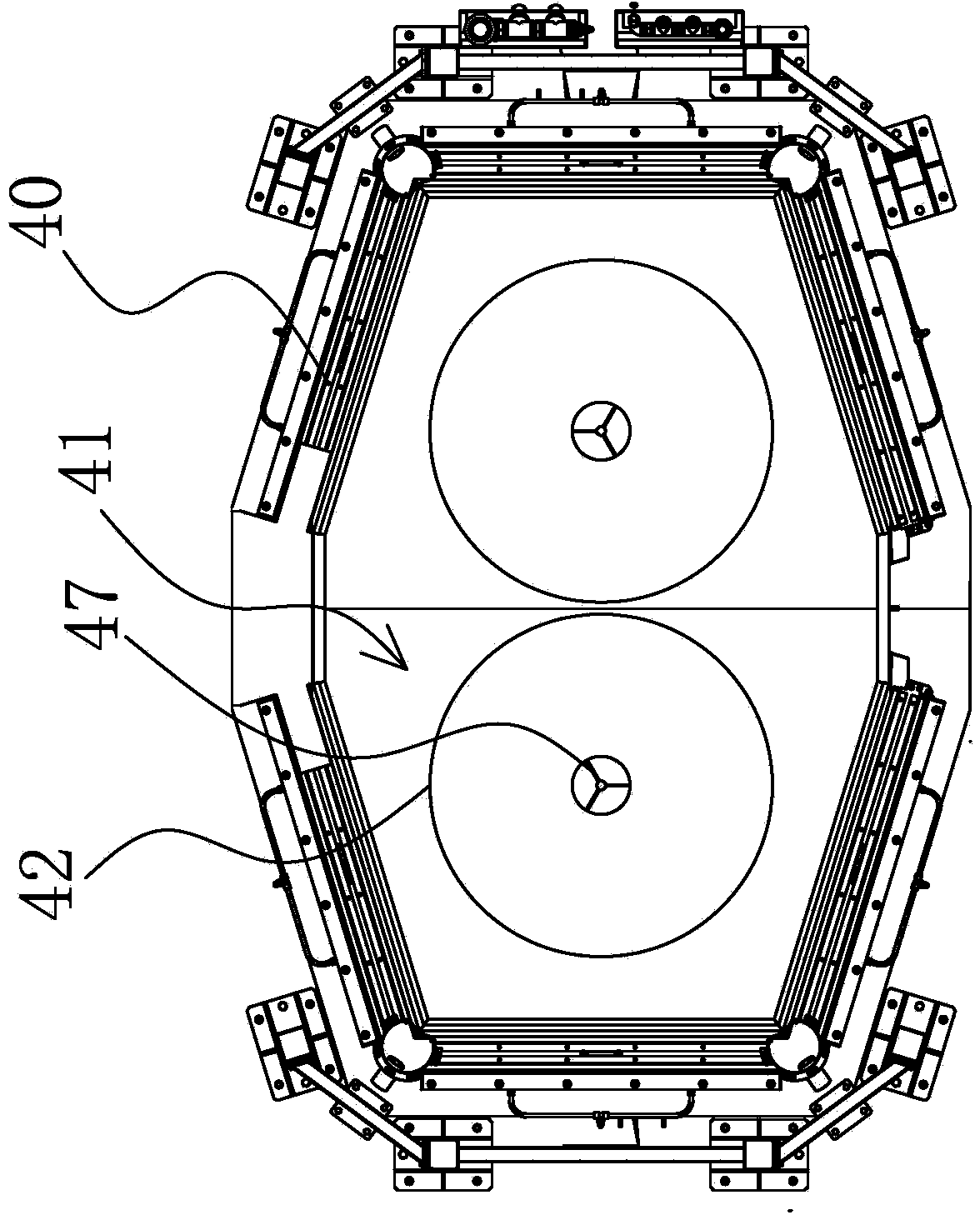

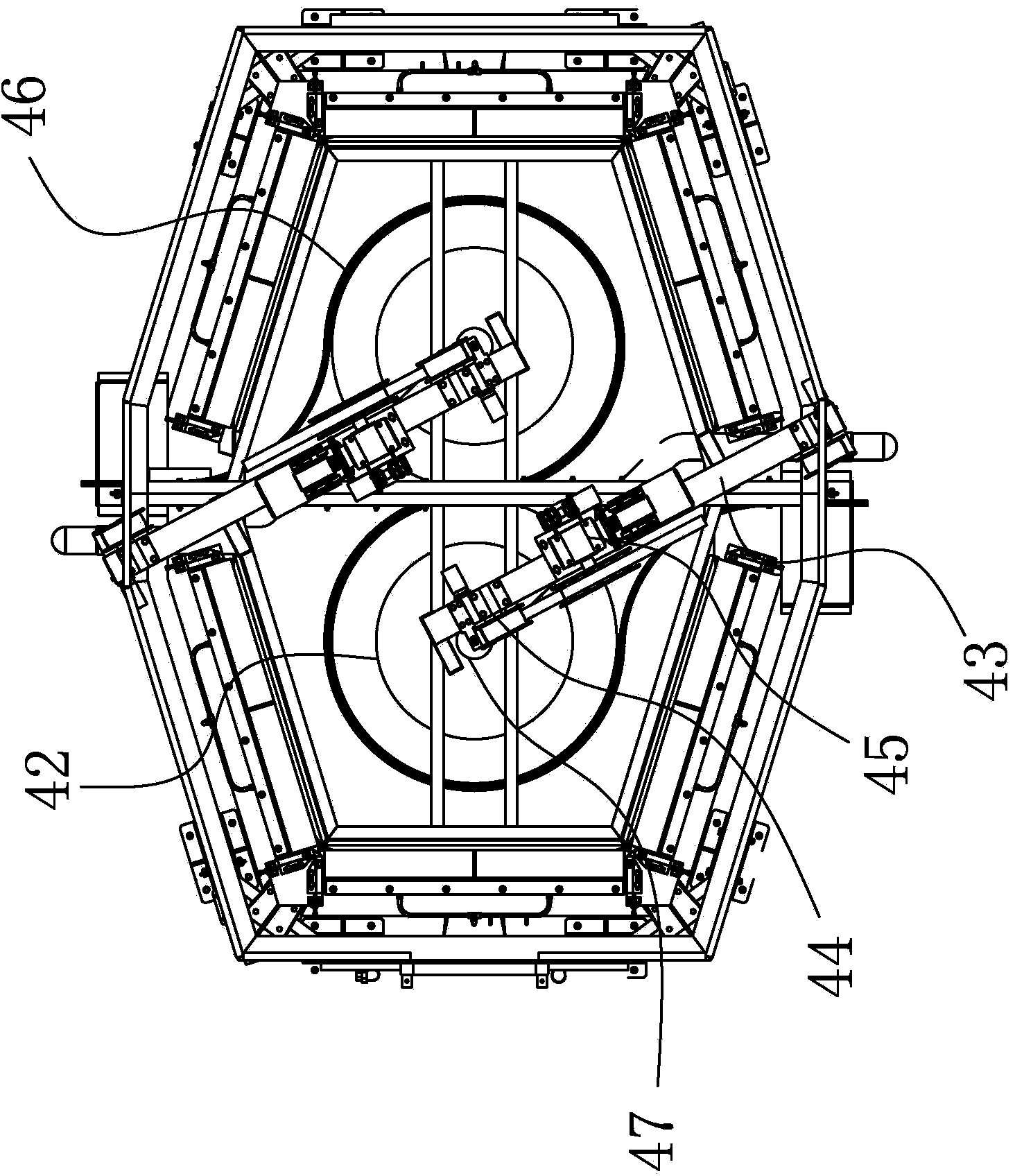

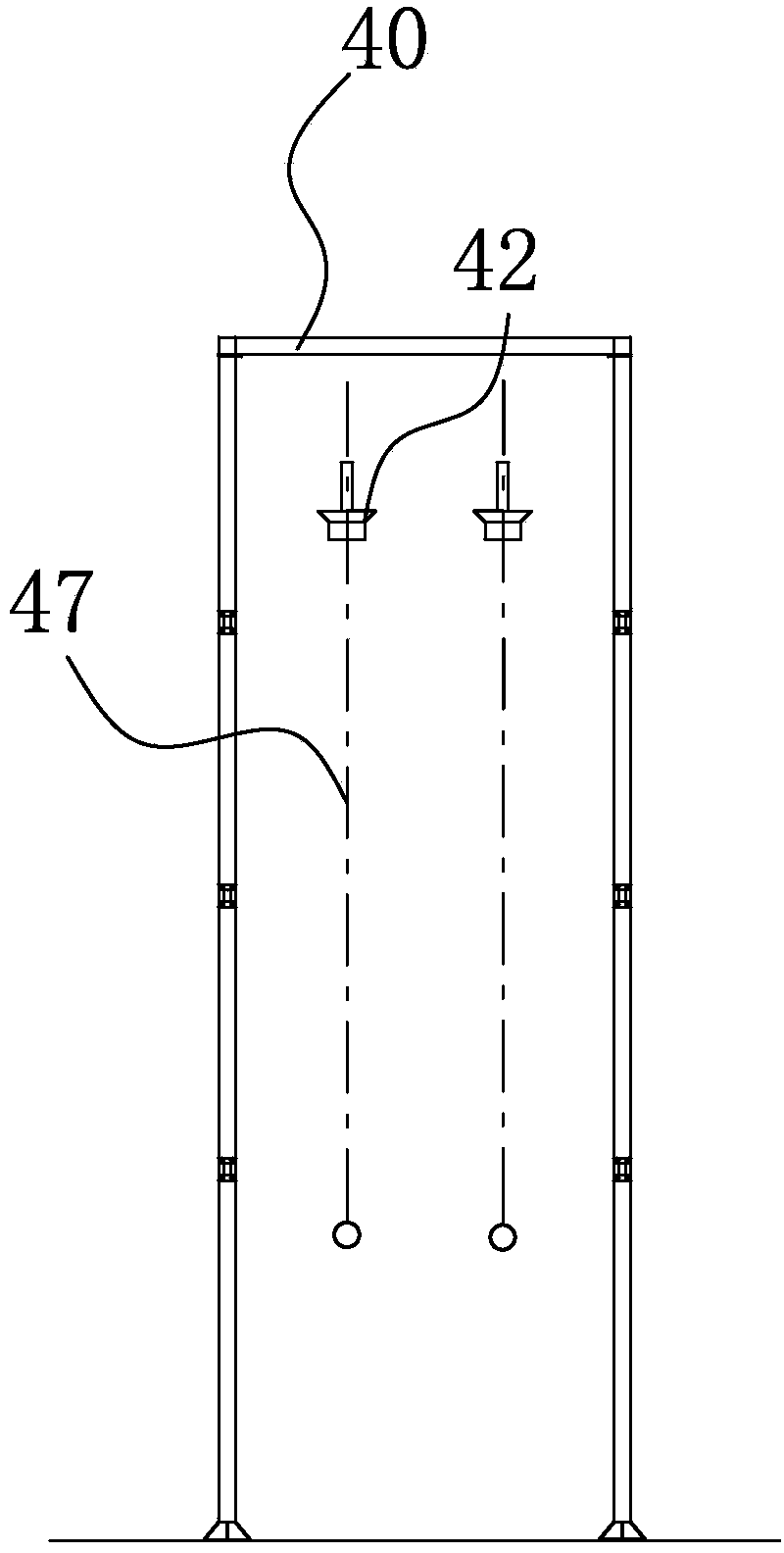

[0015] Such as Figure 1-3 As shown, a nozzle structure for coating equipment includes a nozzle mechanism 41, the nozzle mechanism 41 is arranged in the spray equipment 40, the nozzle mechanism 41 can be lifted in the vertical direction, and the nozzle mechanism 41 is provided with spray holes ( not shown in the figure), the powder can be ejected from the nozzle hole, since the nozzle structure 41 is a prior art, so it will not be repeated here, the nozzle structure 41 is connected to the powder feeding mechanism through a hose, so when the nozzle structure 41 lifts , will not be limited by connecting pipes. The nozzle mechanism 41 includes a vertically arranged guide column 47, the nozzle 42 is sleeved on the guide column 47 and can be raised and lowered along the guide column 47, and the guide column 47 plays a role in positioning in the vertical direction. When the nozzle 42 is raised and lowered, its The position in the vertical direction will not move, thereby ensuring t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com