Method for connecting PE (Polyethylene) winding pipes

A connection method and a technology of winding pipes, which are applied in the direction of pipeline connection layout, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve problems such as high cost, heavy pipe weight, and poor corrosion resistance of metal flanges, and achieve convenient construction , Good anti-floating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] specific implementation plan

[0031] The present invention will be further described below in conjunction with accompanying drawing.

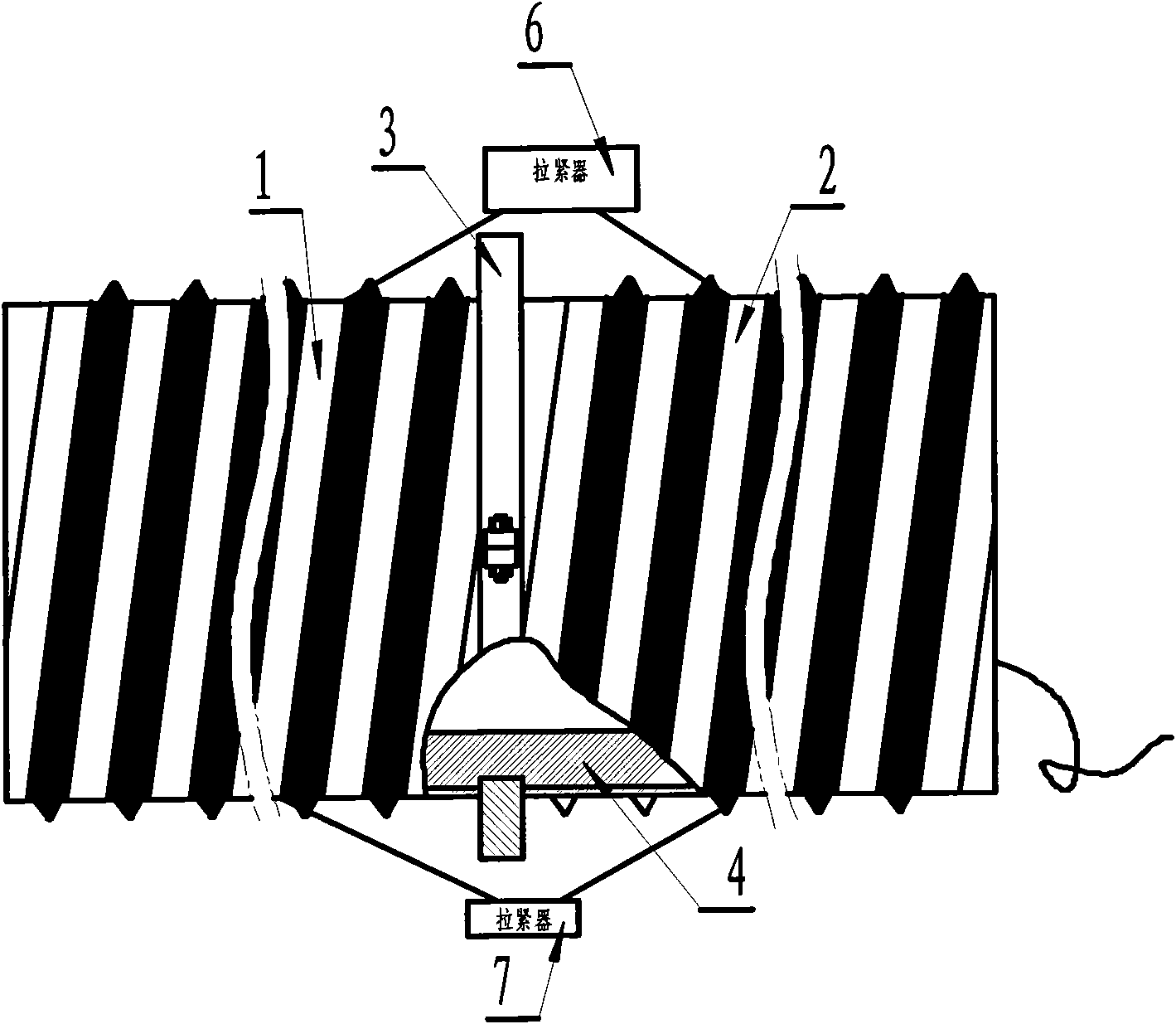

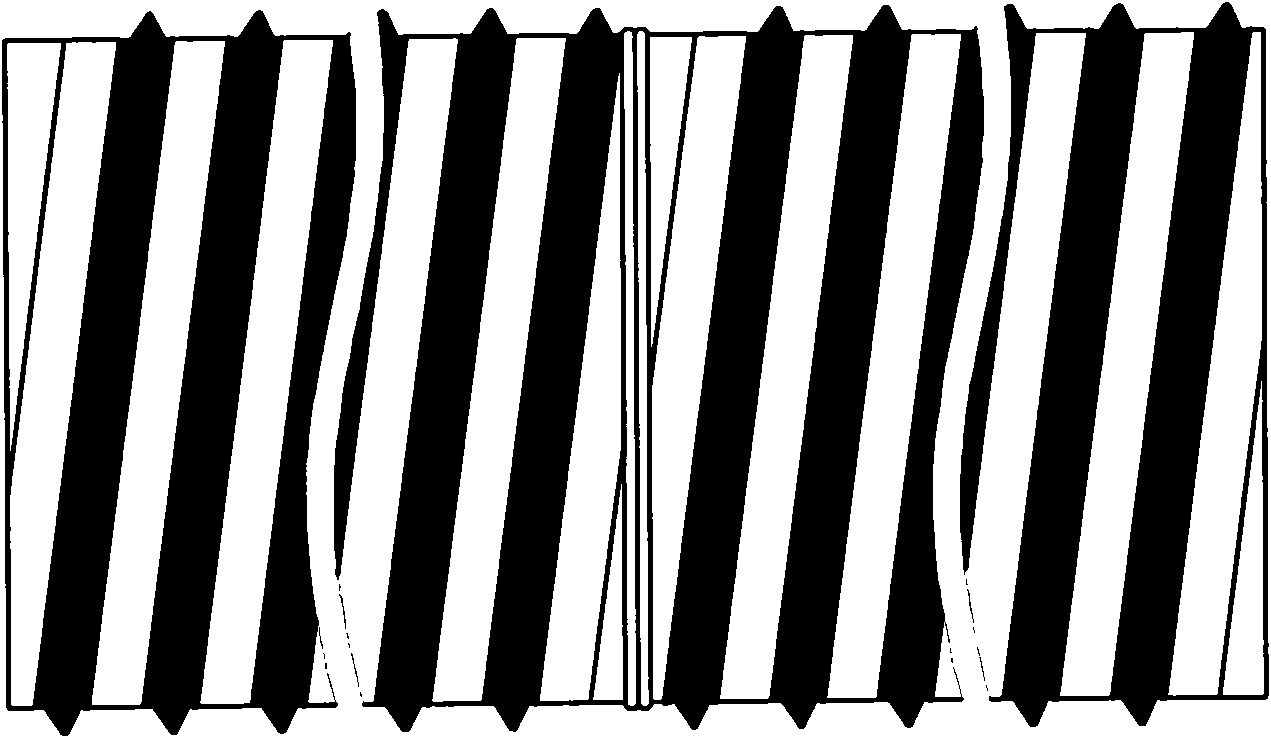

[0032] The PE winding pipe connection method of the present invention needs to be realized by using the heating ring 3 , the winding pipe inner supporting device 4 , and the tensioners 6 and 7 .

[0033] Such as figure 1 As shown, the tensioners 6 and 7 must be placed at equal intervals along the outer circumference of the PE winding pipe to ensure the balance of tension;

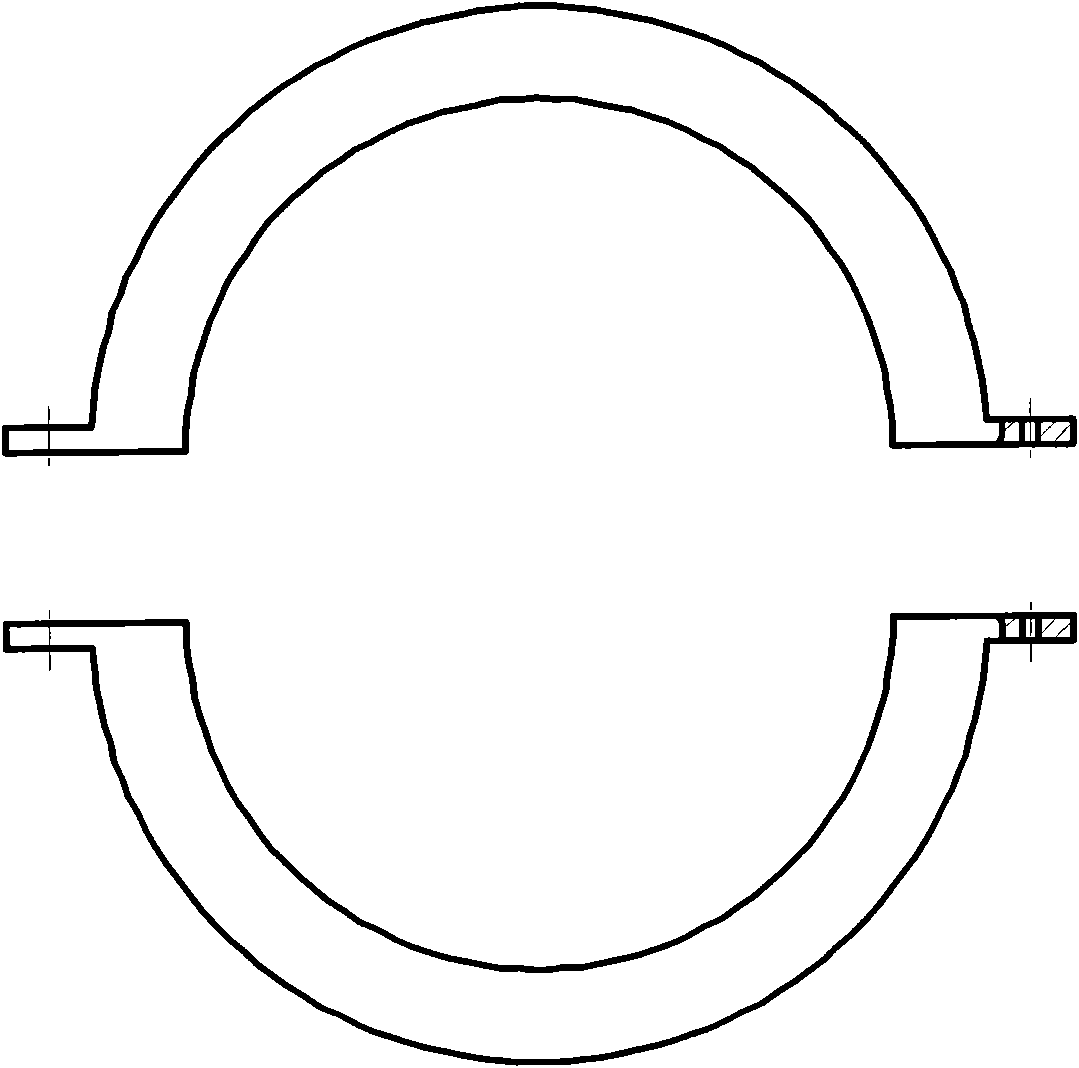

[0034] Such as image 3 As shown, the heating ring has two semicircular structures, which are easy to remove after the heat melting is completed;

[0035] Such as Figure 4 , 5 As shown in , 6 and 7, the winding tube inner support device 4 is composed of two driving sliders 11 and two driven sliders 12, and the outer walls of the driving slider 11 and the driven slider 12 are provided with a heating ring positioning groove 9, The active slider 11 and the driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com