Apparatus for improving hydride vapour phase epitaxy growth GaN material homogeneity

A hydride vapor phase, epitaxial growth technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problem of not meeting the needs of practical applications, and achieve the effect of uniform distribution and uniform airflow distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

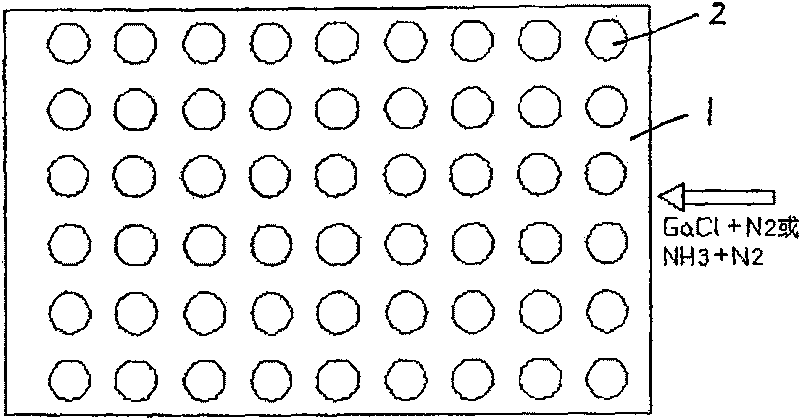

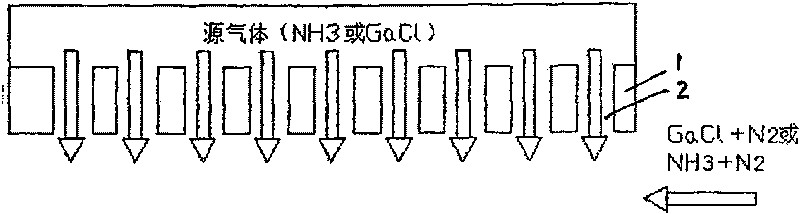

[0013] The arrows in the figure indicate the flow direction of the source gas. There are many small holes 2 evenly distributed in the quartz plate shower head 1. The diameter of the small holes is 1-4mm, and the density of the distributed small holes is 3-20 per square centimeter. The quartz plate shower head is arranged above the surface of the growth substrate and the distance from the substrate is generally 5-20 mm. The shape of the quartz plate shower head can be circular or rectangular.

[0014] There are two ways to implement the technology of the present invention: 1. GaCl gas and carrier gas are sprayed from the shower head to the top of the substrate, and NH3, carrier gas and total N2 are mixed and horizontally enter the top of the substrate where they are mixed with GaCl gas and generated reaction. 2. NH3 gas and carrier gas are sprayed from the shower head to the top of the substrate, and GaCl gas, carrier gas and total N2 are mixed and then horizontally enter the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com