Intensively stacked orifice plate vertical face inclined axis driving input and output device of distribution instrument

A technology of tilting axis and plate facade, applied in the field of culture medium sub-packaging equipment, can solve the problems of complex motor action process, increase the complexity of control system, increase the number of drivers, etc., achieve high space utilization, good compatibility, processing Effects with low requirements on precision and mounting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific structure and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings and multiple embodiments.

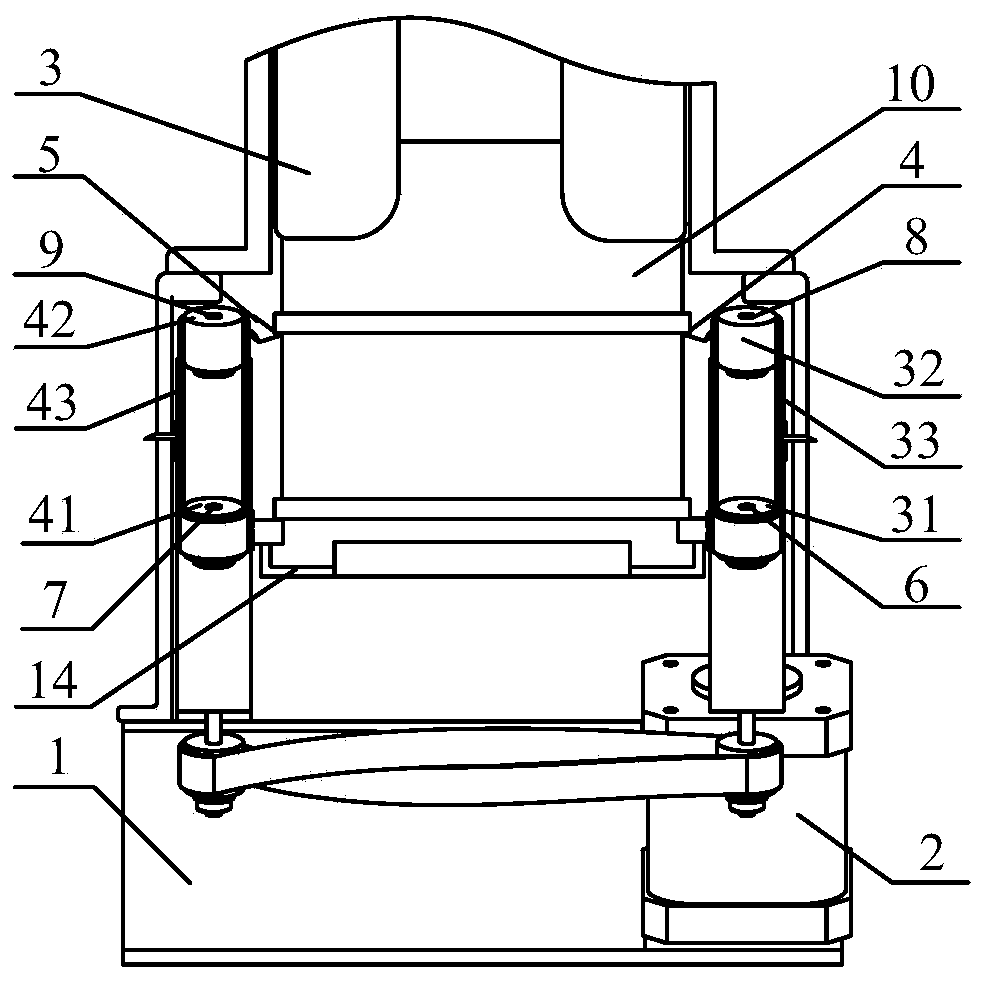

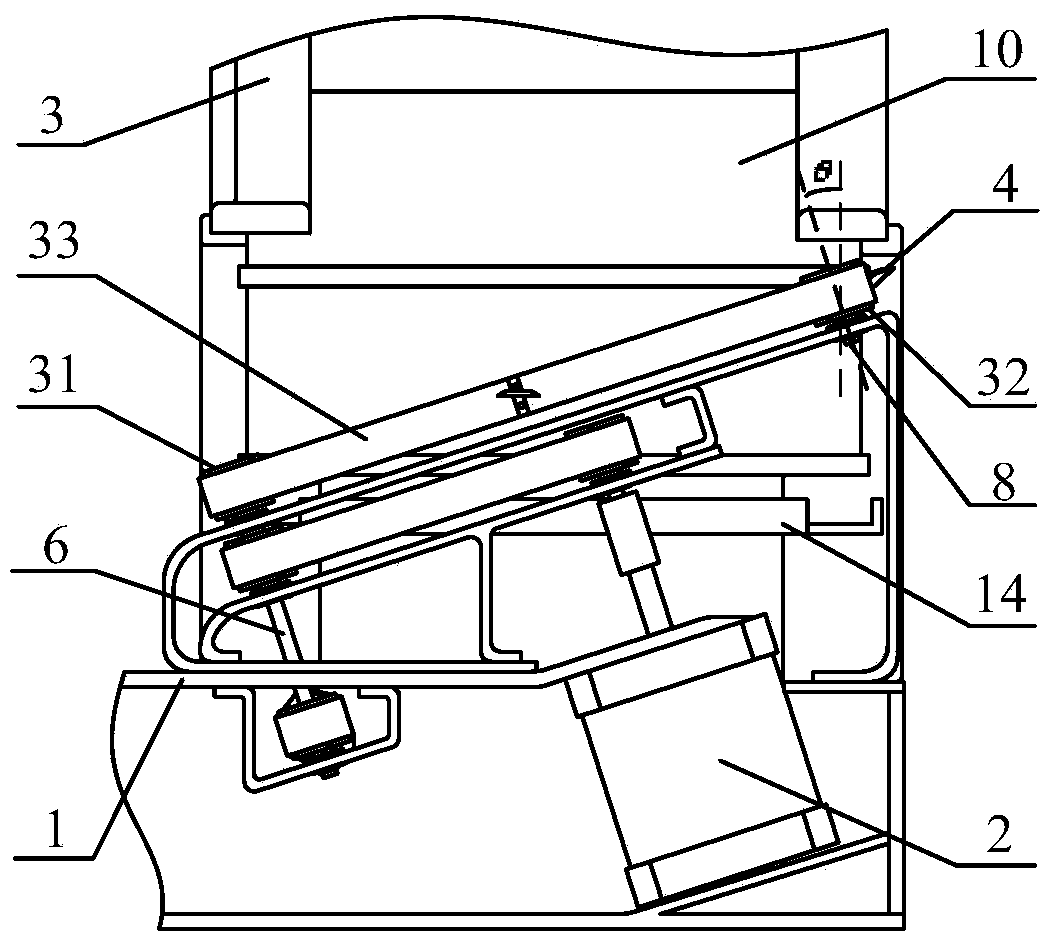

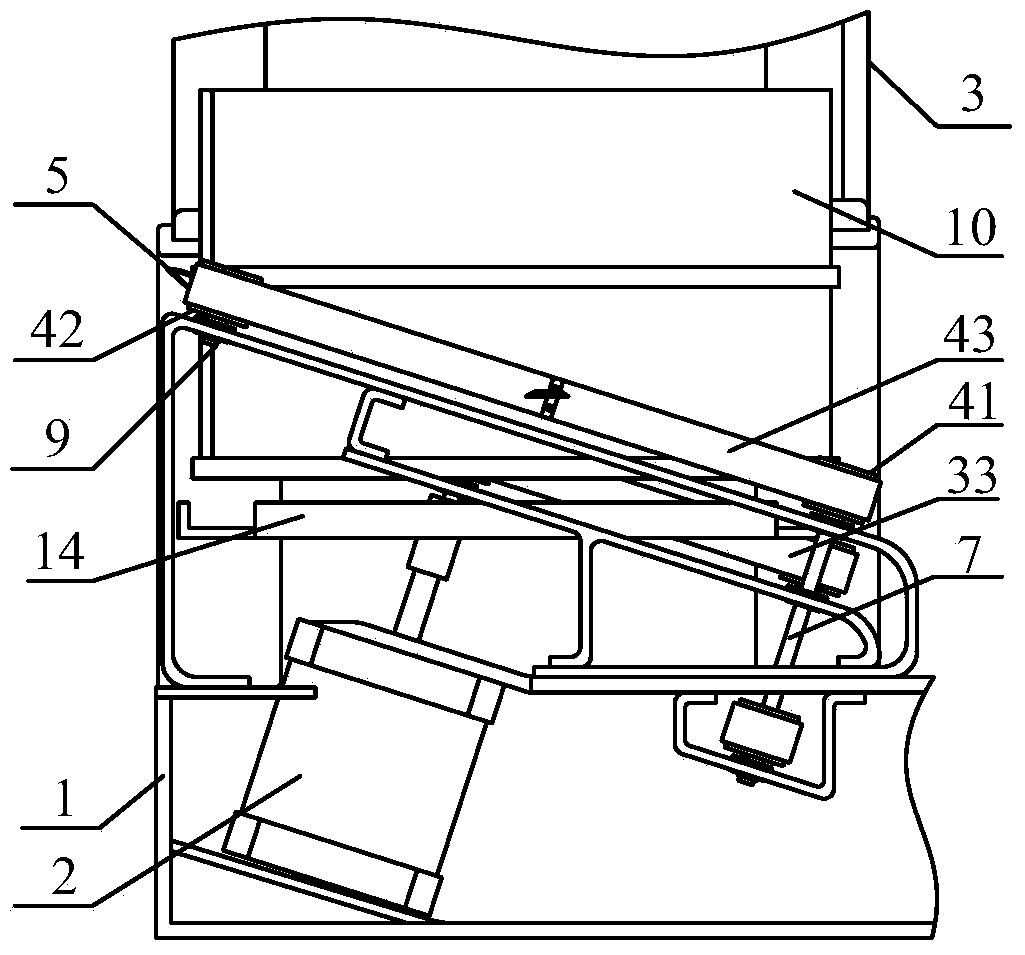

[0033] An embodiment of the inclined shaft belt drive in and out device of the close-packed orifice plate facade of the packaging instrument designed by the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5As shown, it includes a base 1, a driver 2 and an orifice box 3; the driver 2 is fixedly installed in the base 1, the orifice box 3 is arranged on the base 1, and at least one orifice plate is accommodated in the orifice box 10. The device also includes a façade inclined shaft drive lifting mechanism, the lifting mechanism includes a first support block 4, a second support block 5, a first driving shaft 6, a second driving shaft 7, and a first driven shaft 8 , the second driven shaft 9, the first transmission mechanism, the second transmission mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com