Preparation method for 3-chloropropionylchloride

A technology for chloropropionyl chloride and acrylic acid, which is applied in the preparation of acyl halide, the preparation of organic compounds, the preparation of carboxylate, etc., can solve the problems of high risk, complicated preparation method of 3-chloropropionyl chloride, etc., and achieves less post-processing steps. , The effect of high product yield and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

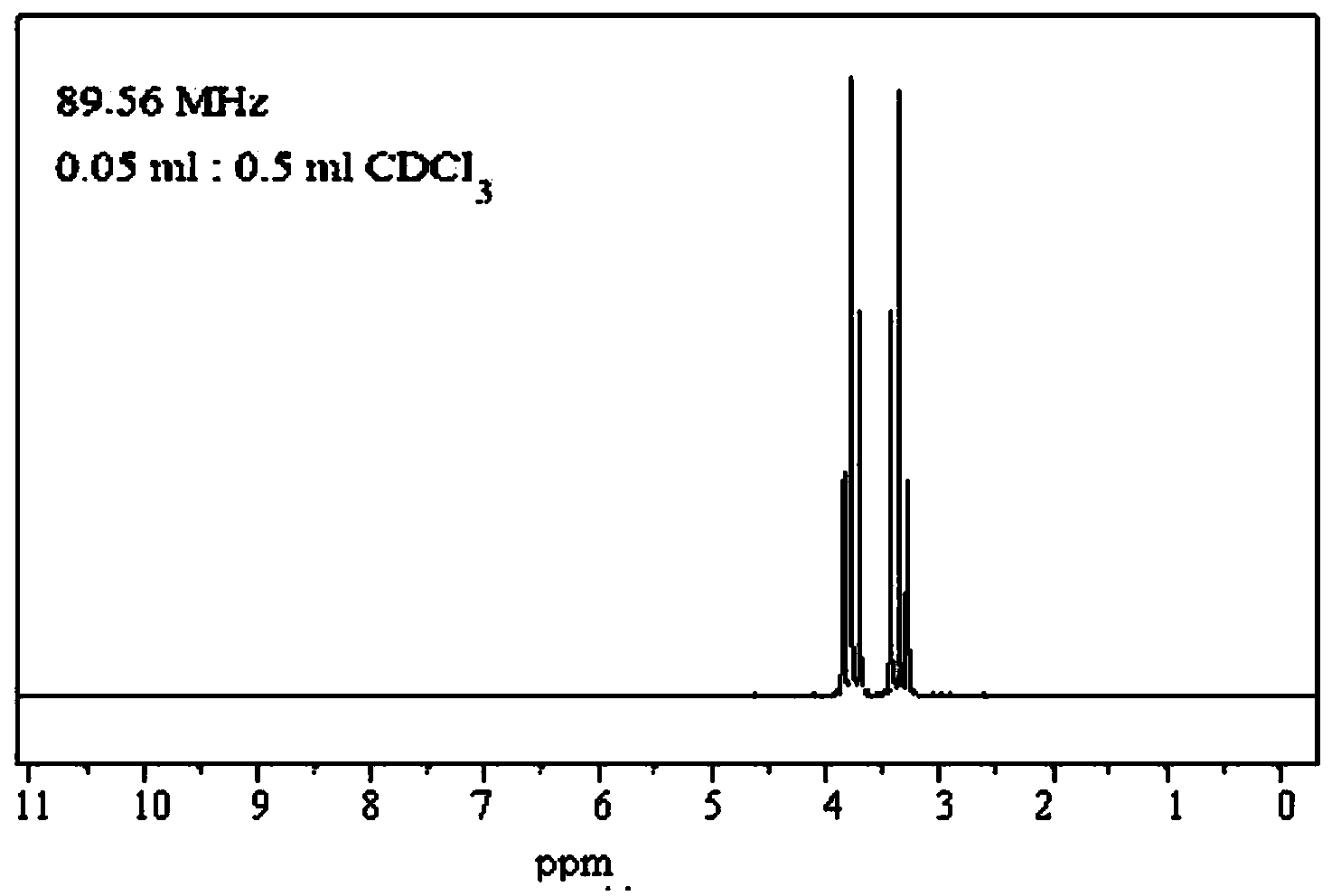

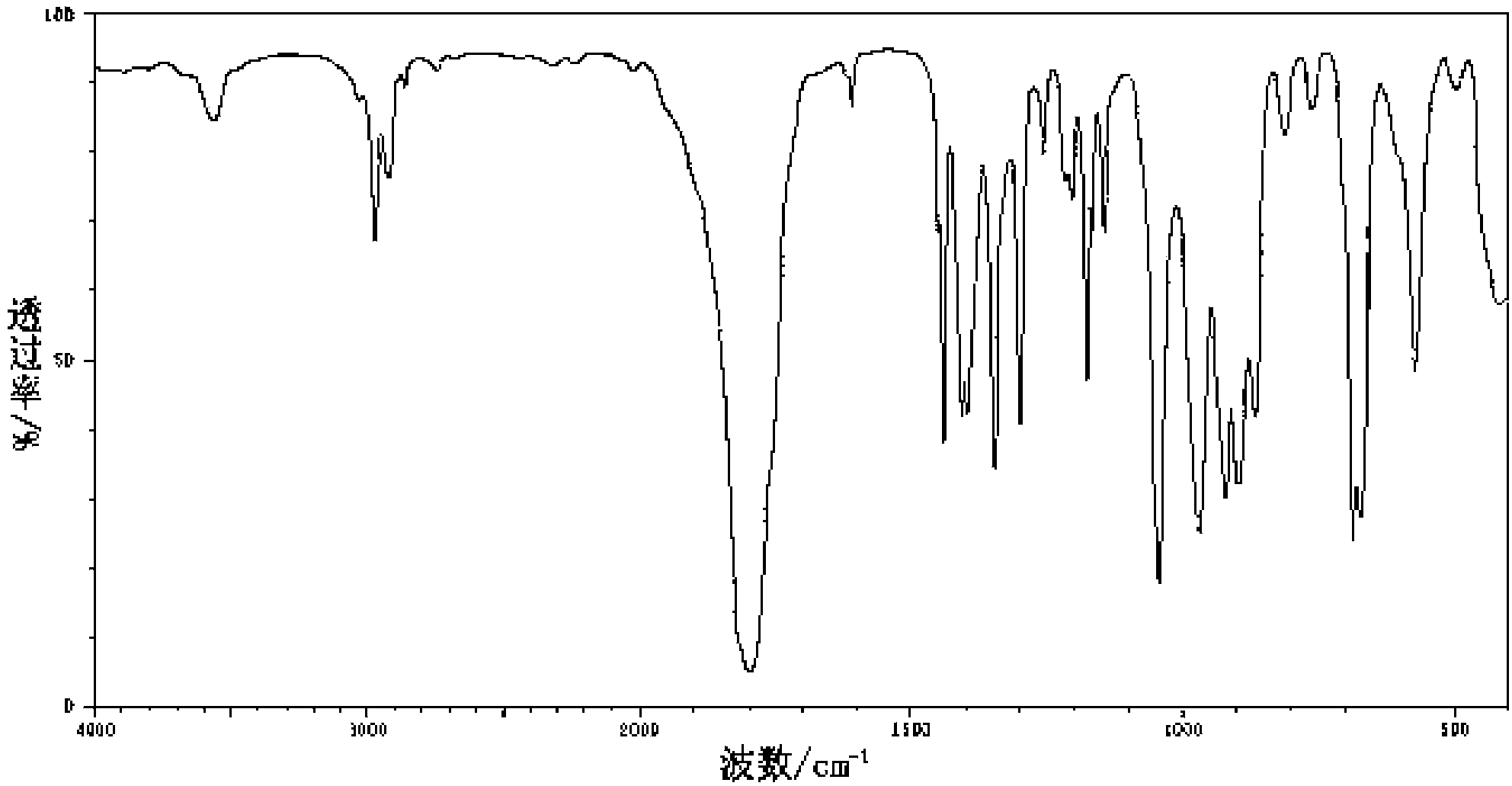

[0011] Add 200g of acrylic acid and 2g of water into a four-neck flask equipped with a stirrer, a thermometer and a condenser, add 360g of thionyl chloride dropwise below 20°C, slowly heat and reflux for 6 hours after dropping, and then distill at atmospheric pressure to 120°C. Distilled under reduced pressure to obtain 303g product again, yield 86%, content 99.1%. From figure 1 and figure 2 It can be confirmed that the final product obtained in this example is 3-chloropropionyl chloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com