Q&P heat treatment method of TRIP590 steel of C-Mn-Al series

A heat treatment method and c-mn-al technology, which is applied in the field of material heat treatment, can solve the problems that the process parameters cannot be reasonably matched with each other and cannot be achieved, and achieve the effect of short heat treatment process time, reliable numerical value and saving heat treatment time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Remove rust and oil from the C-Mn-Al series TRIP590 cold-rolled steel plate, and clean it to avoid uneven heating during the heat treatment process.

[0025] (1) Austenitization: The pre-treated TRIP590 cold-rolled steel sheet is kept at 1080°C for 3 minutes;

[0026] (2) Quenching: After the heat preservation is completed, it is rapidly cooled to 200 °C for 25s;

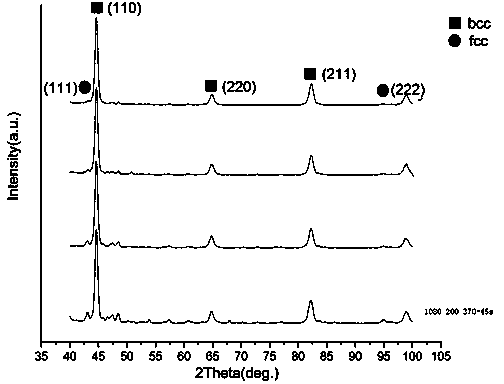

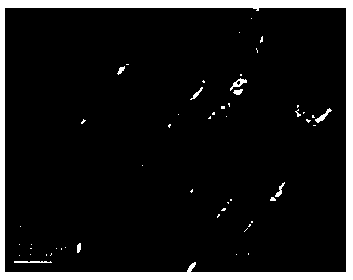

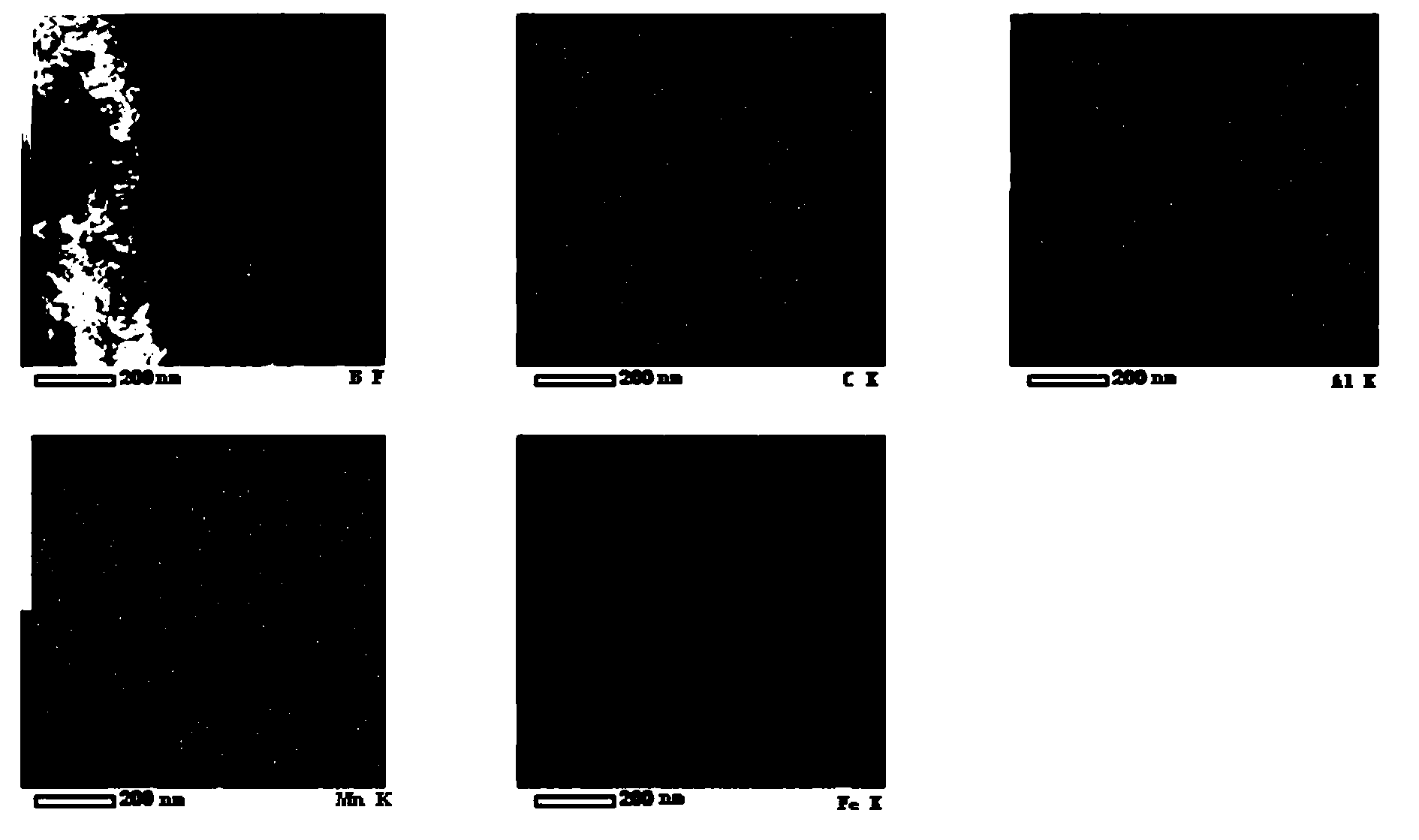

[0027] (3) Partitioning: After quenching, rapid heating is performed for partitioning, the partitioning temperature is controlled at 370 °C, the partitioning time is 45s, and finally water quenching is performed to obtain a steel with enhanced performance. The XRD pattern is as follows figure 1 As shown in the calculation formula, the volume fraction of retained austenite is more than 16%; the TEM image is as follows figure 2 A large amount of film-like distribution and retained austenite between the martensitic laths can also be seen from the TEM image; the STEM image is shown in image 3 It can be seen f...

Embodiment 2

[0030] Remove rust and oil from the C-Mn-Al series TRIP590 cold-rolled steel plate, and clean it to avoid uneven heating during the heat treatment process.

[0031] (1) Austenitization: The pre-treated TRIP590 cold-rolled steel sheet is kept at 1150°C for 2min;

[0032] (2) Quenching: After the heat preservation is completed, it is rapidly cooled to 210 °C for 30s;

[0033] (3) Partitioning: After quenching, rapid heating is performed for partitioning, the partitioning temperature is controlled at 350 °C, the partitioning time is 60s, and finally water quenching is performed to obtain steel with enhanced properties.

[0034] After testing, the tensile strength is 967MPa, the elongation after fracture is 22.5%, and the strong-plastic product is 21757MPa%, which is much higher than that of the steel produced by Q&P treatment with TRIP590 as the base material.

Embodiment 3

[0036] Remove rust and oil from the C-Mn-Al series TRIP590 cold-rolled steel plate, and clean it to avoid uneven heating during the heat treatment process.

[0037] (1) Austenitization: The pre-treated TRIP590 cold-rolled steel sheet is kept at 1000 °C for 5 minutes;

[0038] (2) Quenching: After the heat preservation is completed, it is rapidly cooled to 220°C for 10s;

[0039] (3) Partitioning: After quenching, rapid heating is performed for partitioning, the partitioning temperature is controlled at 360 °C, the partitioning time is 30s, and finally water quenching is performed to obtain steel with enhanced performance.

[0040] After testing, the tensile strength is 970MPa, the elongation after fracture is 22.2%, and the strong-plastic product is 21534MPa%, which is much higher than that of the steel produced by Q&P treatment with TRIP590 as the base material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Strong plastic product | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com