Heating furnace slab positioning device and positioning method thereof

A technology for positioning devices and heating furnaces, which is applied to heat treatment furnaces, furnaces, furnace types, etc., can solve the problems of no calibration, no slab width measurement process, and slab straightening process, etc., so as to improve input rate and protect The effect of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

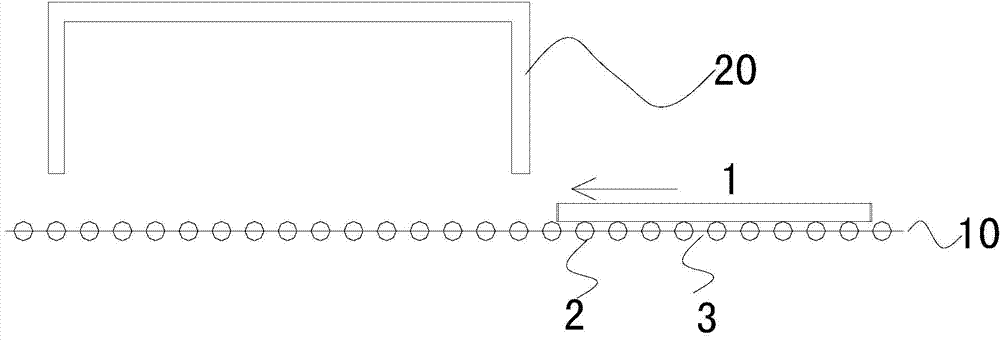

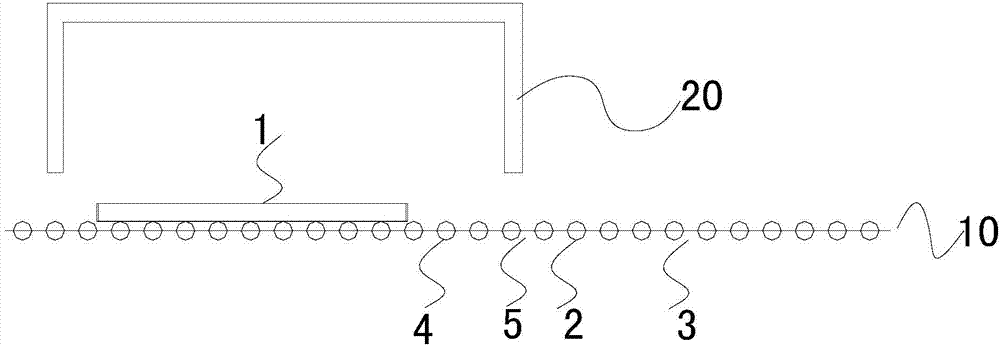

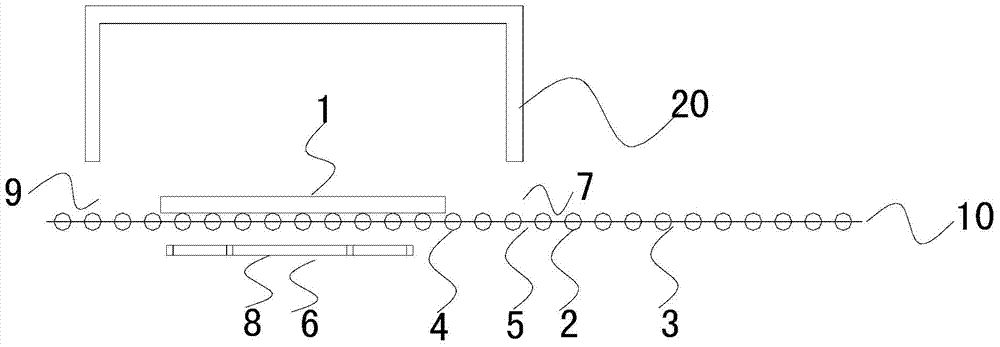

[0036] Such as Figure 1-Figure 4 As shown, a heating furnace slab positioning device includes: a furnace side roller table encoder 2, a furnace side cold and hot metal detector 3, a furnace front roller table encoder 4, a furnace front cold and hot metal detector 5, and Mechanism 6, width-measuring metal detector 7, encoder 8 of push-up mechanism, range finder 9, roller table group 10 and control unit.

[0037] The roller table encoder 2 on the side of the furnace, the roller table encoder 4 in front of the furnace, and the encoder 8 of the pushing mechanism can all use the incremental RHI58 or absolute value AHM58 products of Pepperl+Fuchs P+F.

[0038] The hot and cold metal detector 3 on the side of the furnace, the hot and cold metal detector 5 in front of the furnace, and the metal detector 7 measuring the width can use the laser grating products of Changzhou Lucheng Sensor Co., Ltd.

[0039] The pushing mechanism 6 is in the form of horizontal movement and adopts a pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com