Forced intermittent special mixing apparatus for asphalt mixture regeneration

A technology of asphalt mixture and mixing equipment, which is applied in the direction of roads, road repairs, roads, etc. It can solve the problems of less than 20% of the reasonable utilization rate of recycled asphalt pavement materials, the reduction of the overall constant of the equipment, and it is not suitable for mixing and mixing evenly, so as to facilitate installation Debugging and daily operation and maintenance, reducing the overall height of the equipment, facilitating installation, debugging and daily operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

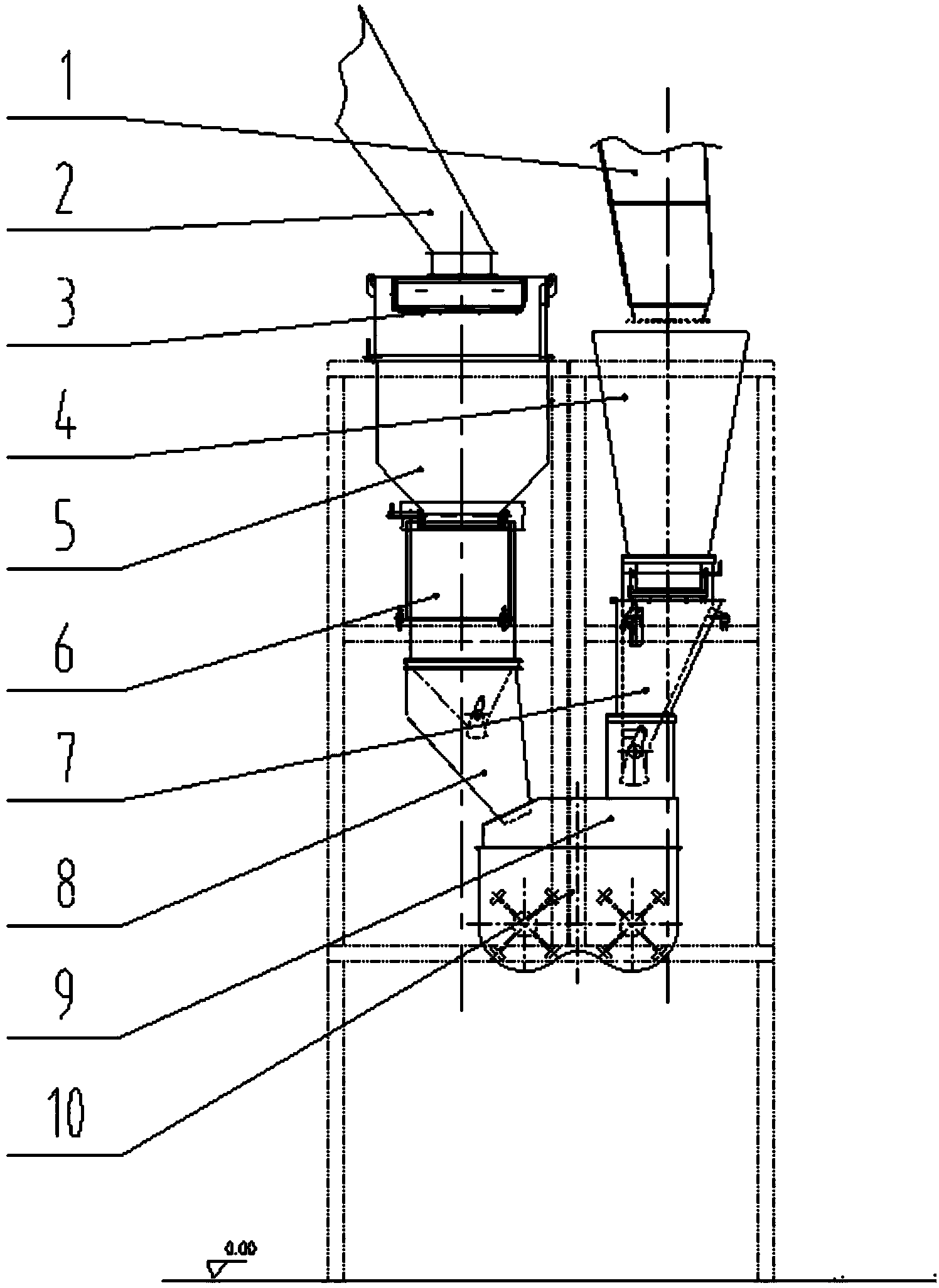

[0032] Combine below figure 1 , to further describe the specific implementation of the patent of the present invention, the following examples are only used to more clearly illustrate the technical solutions of the patent of the present invention, but not to limit the scope of protection of the patent of the present invention.

[0033] Such as figure 1 As shown, the technical scheme of the specific implementation of the patent of the present invention is:

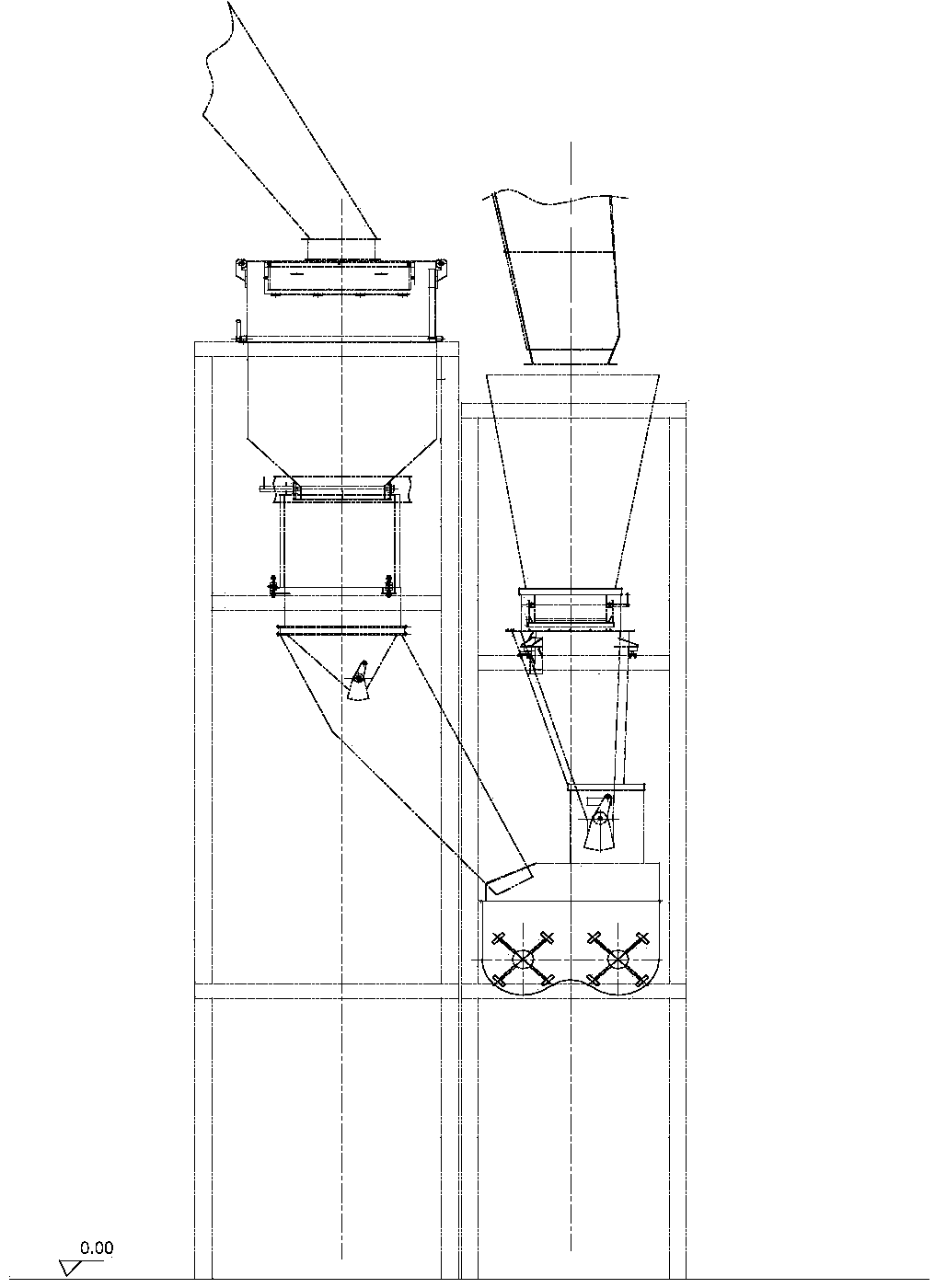

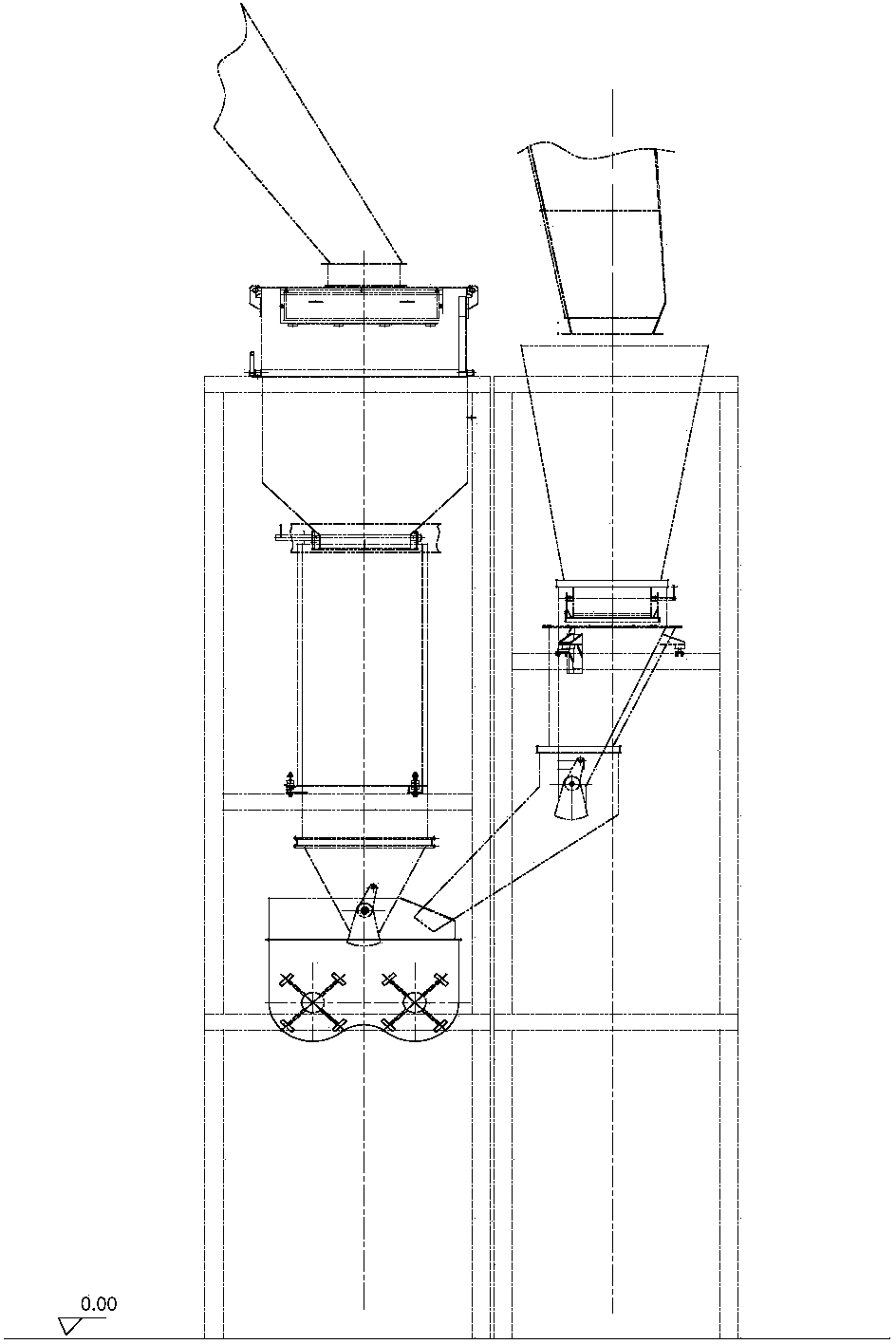

[0034] The drying, caching, weighing and other components required for regenerative production are optimized and integrated with the main building of the forced batch conventional asphalt mixing plant, and the layout and position of the mixing pot (10) are redesigned. figure 2 and image 3 Choose a suitable position between the two extreme positions shown for rearrangement, the principle is to ensure that the reclaimed material (RAP) can be directly discharged into the mixing pot (10).

[0035] The capacity of the mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com