Manufacturing method of semiconductor device test sample

A manufacturing method and semiconductor technology, applied in the semiconductor field, can solve problems such as batch wafer defects, and achieve the effect of increasing the rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

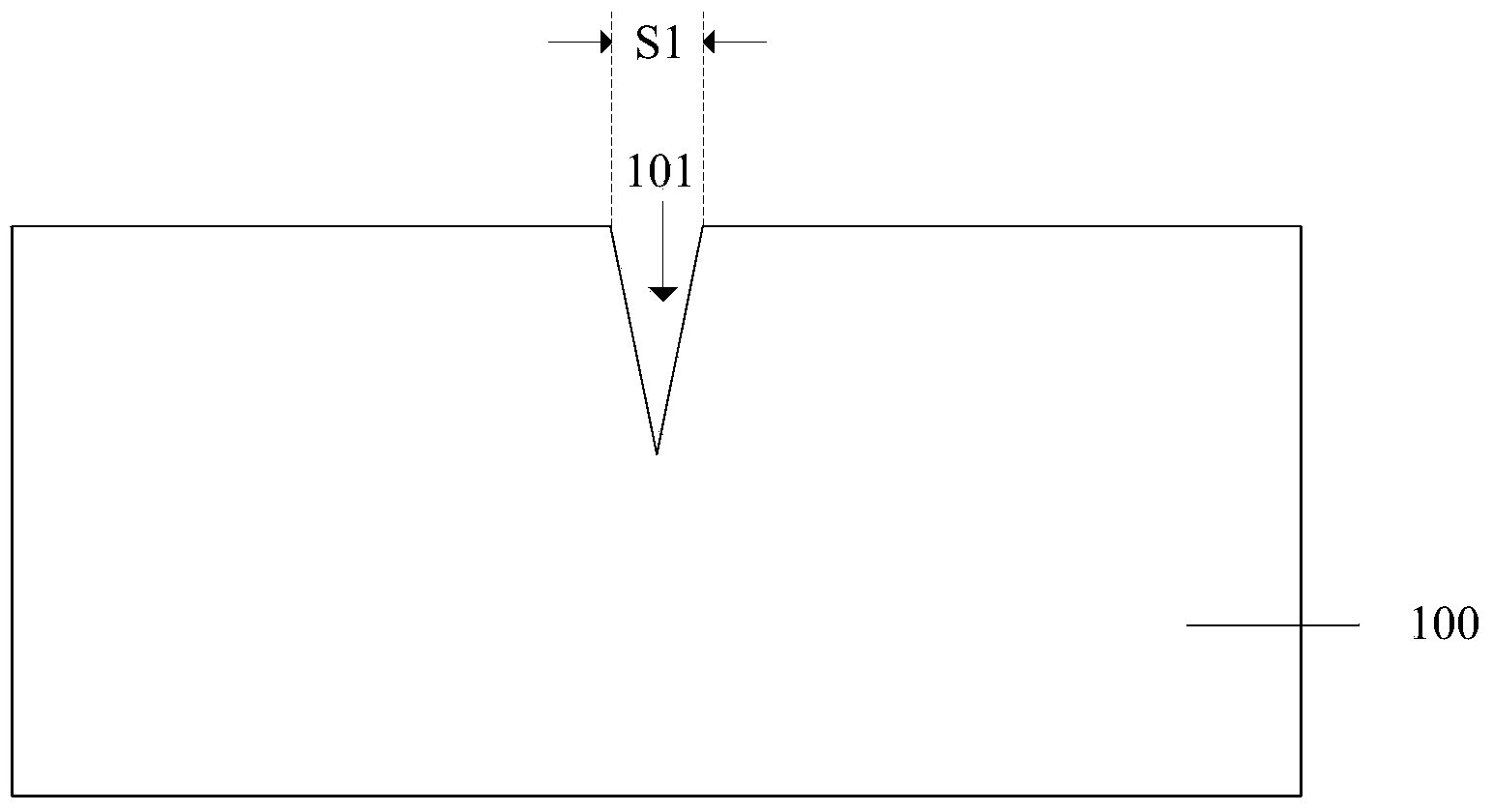

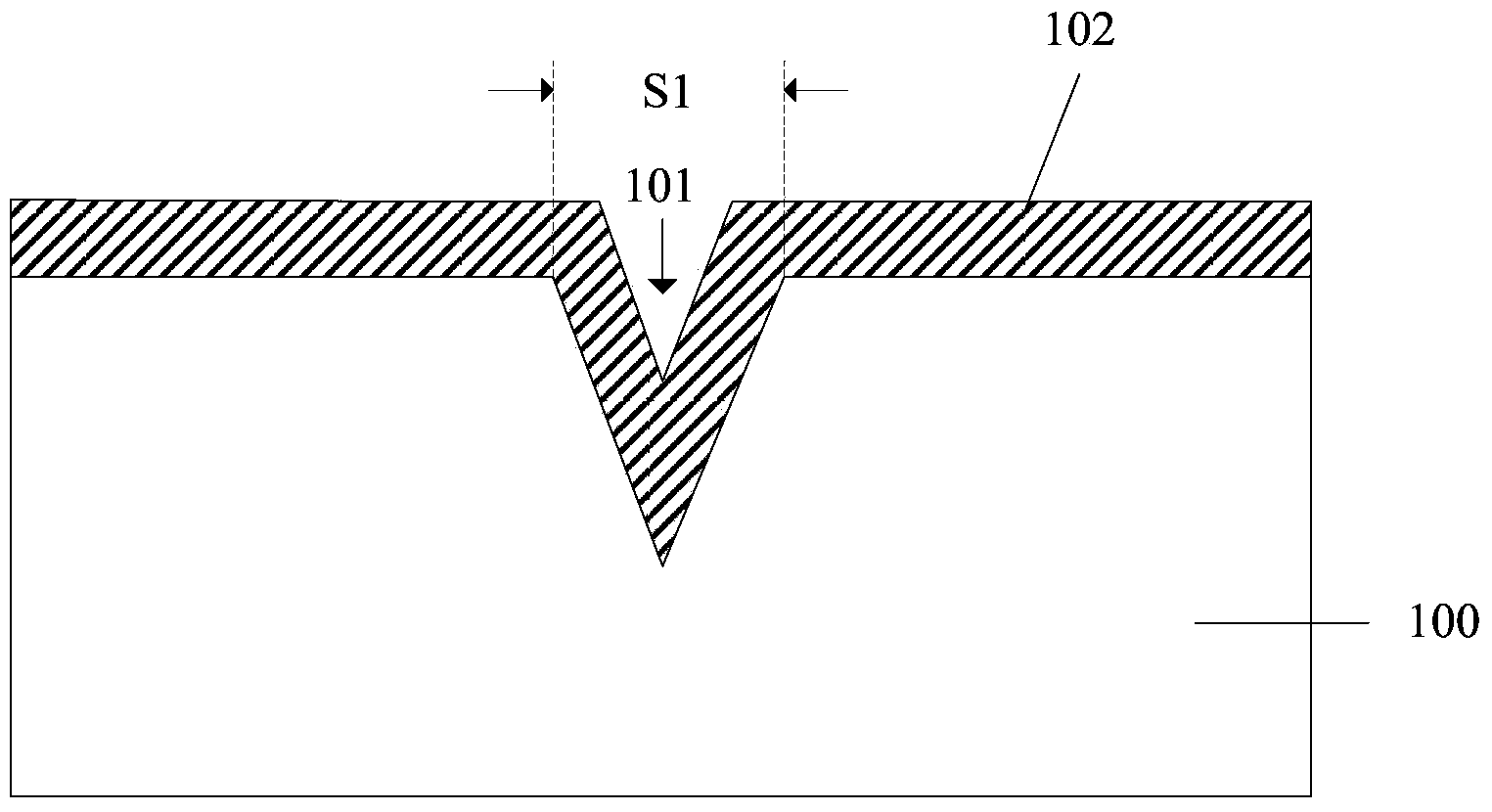

[0023] In the existing manufacturing process of semiconductor devices, defects such as dents with small sizes often occur. In the detection of defects such as dents with small sizes, it is difficult for the detection equipment to capture the defects, which is easy to cause batch failure. Wafers are scrapped due to defects, resulting in losses.

[0024] In order to solve the above-mentioned technical problems, the present invention provides a method for manufacturing test samples of semiconductor devices, so that wafer inspection equipment can more sensitively capture defects such as dents with smaller sizes, and monitor such defects in time to reduce Probability of failure of small semiconductor devices.

[0025] The detection method of semiconductor device defect of the present invention roughly comprises the following steps:

[0026] Provide a substrate; perform at least one oxidation treatment on the substrate, the oxidation treatment includes the steps of forming an oxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com