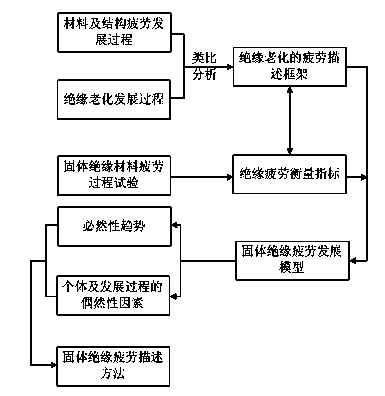

Fatigue test device and method for solid insulation degradation process

A technology of solid insulation and fatigue testing, which is applied in the direction of testing dielectric strength, etc., can solve the problems of few mechanical performance parameters, and achieve the effect of reducing costs and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

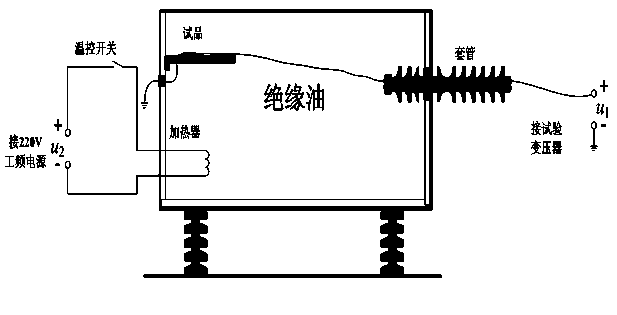

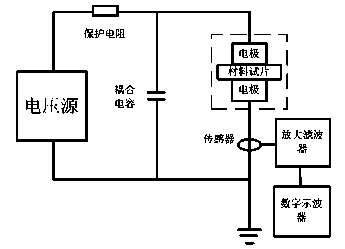

[0038] test bench and circuits such as figure 1 and figure 2 shown. The experimental part includes a glass cabinet, a platform assembly set in the glass cabinet for placing the tested product, a high-voltage system and a low-voltage system; the glass cabinet is filled with insulating oil; the glass cabinet is supported on the ground by insulating pillars; the high-voltage Part of the system is set inside the glass cabinet, and the other part is set outside the glass cabinet; part of the low-voltage system is set inside the glass cabinet, and the other part is set outside the glass cabinet;

[0039] The platform assembly includes a platform and positive and negative electrodes, and the tested product is placed between the positive and negative electrodes;

[0040] The high pressure system includes:

[0041] The high-voltage system includes a high-voltage part and an insulating part; the high-voltage part includes a test transformer and its lead wires; the insulating part in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com