Semiconductor equipment machine quality monitoring method and system

A quality monitoring and semiconductor technology, applied in general control systems, control/regulation systems, computer control, etc., can solve the problems of manual calculation and input prone to errors, untimely, incomplete data, etc., to eliminate errors and improve product quality. Accurate and complete effect of rate and data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

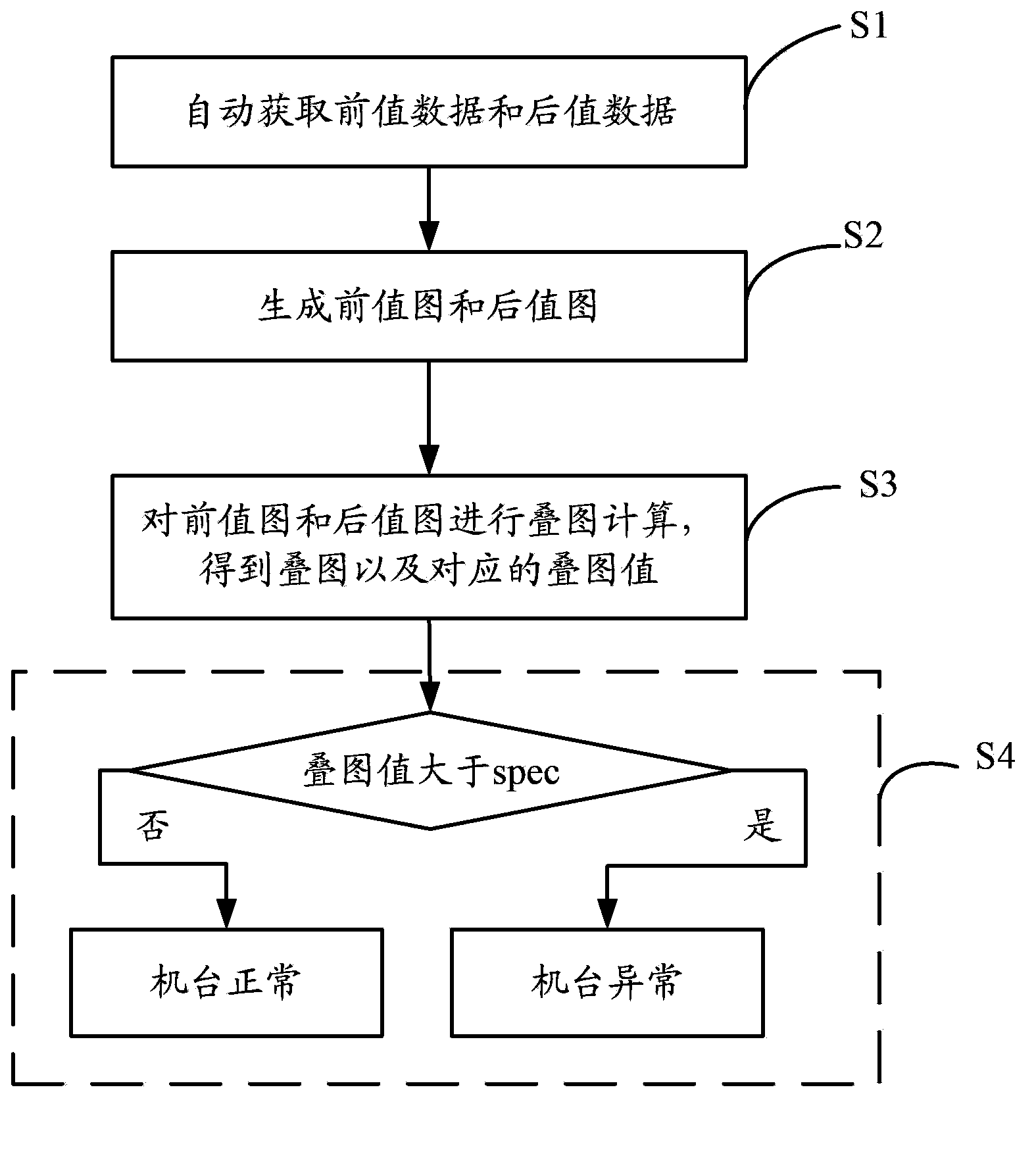

[0035] The invention discloses a method for monitoring the quality of a semiconductor equipment machine, the method comprising:

[0036] S1. Automatically acquire the pre-value data of the machine quality monitoring in the previous process and the post-value data of the machine quality monitoring in the next process, wherein the pre-value data and the post-value data are the number of defects on the wafer in the process;

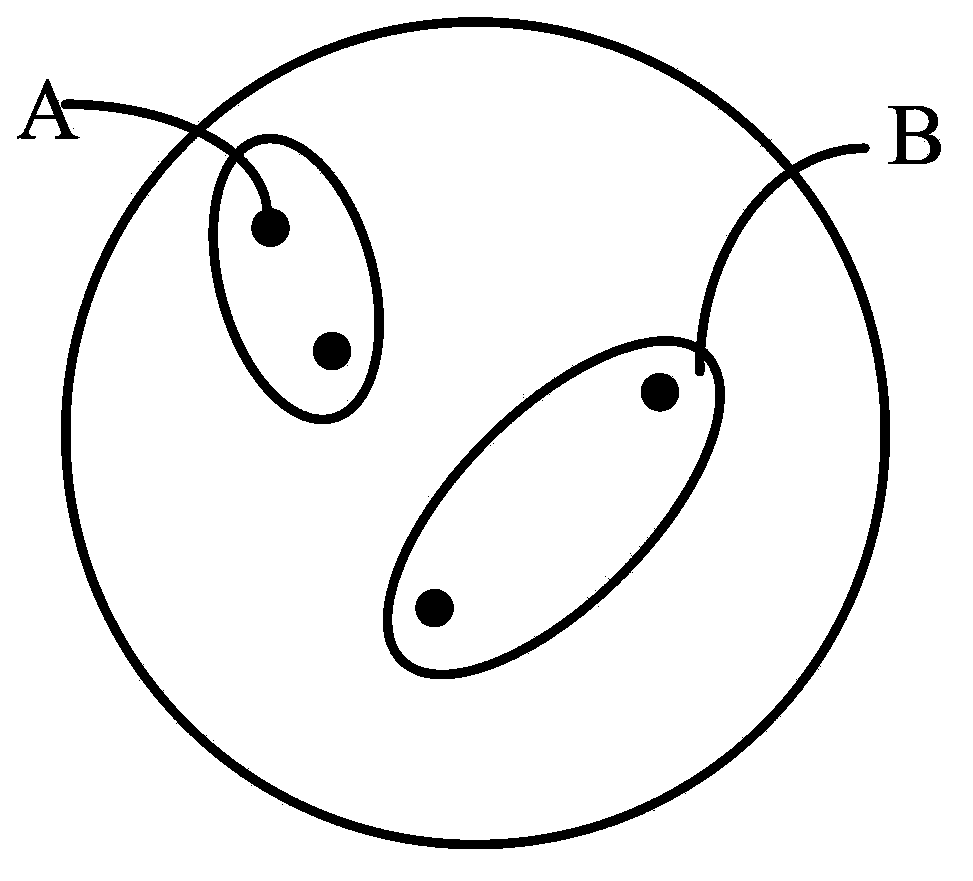

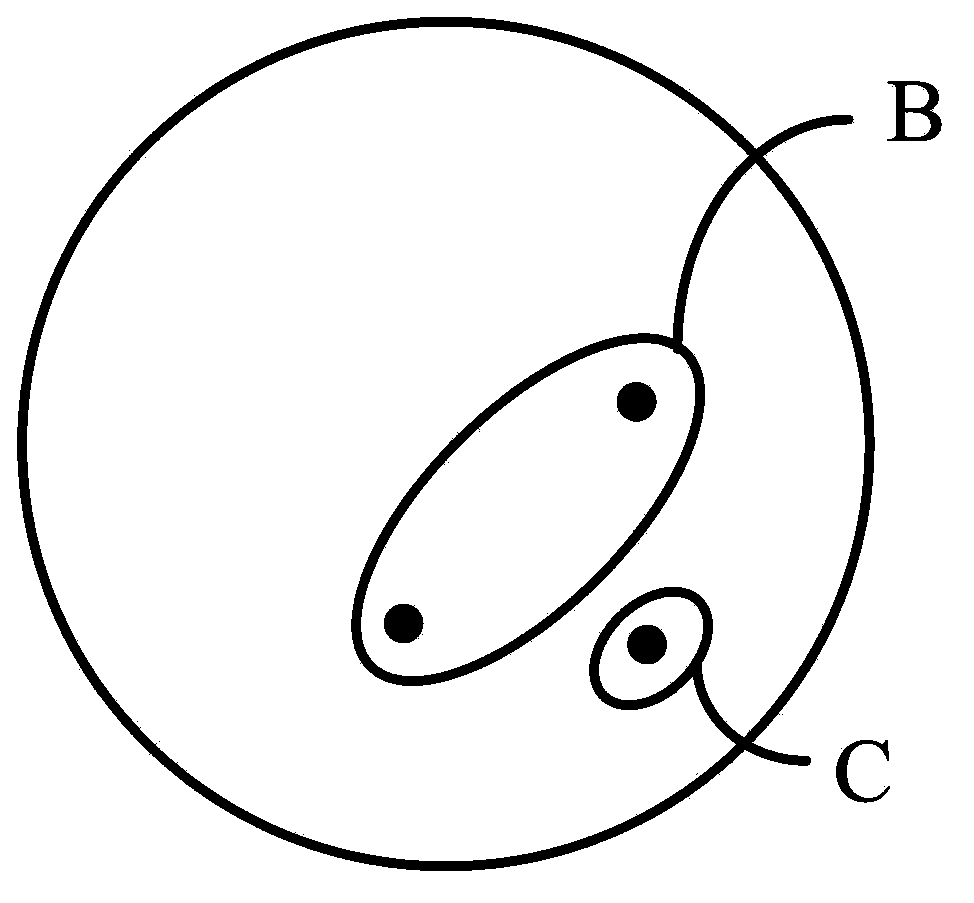

[0037] S2. Correspondingly generate a previous value graph and a rear value graph from the previous value data and the rear value data;

[0038] S3. Perform overlay calculation on the pre-value map and the post-value map to obtain the overlay and corresponding overlay values, wherein the overlay value is the number of newly added defects in the two processes;

[0039] S4. Comparing the overlay value with the system preset threshold spec, if the overlay value is less than or equal to spec, it is determined that the machine is normal; if the overlay value is g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com