Internal fluid heat exchange system

A heat exchange system and internal source technology, applied in the direction of electrical solid devices, semiconductor devices, semiconductor/solid device components, etc., can solve problems such as poor stress, difficult structure independence, and power-off protection, so as to avoid mechanical noise and wear, improve work efficiency, reduce the effect of heat displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

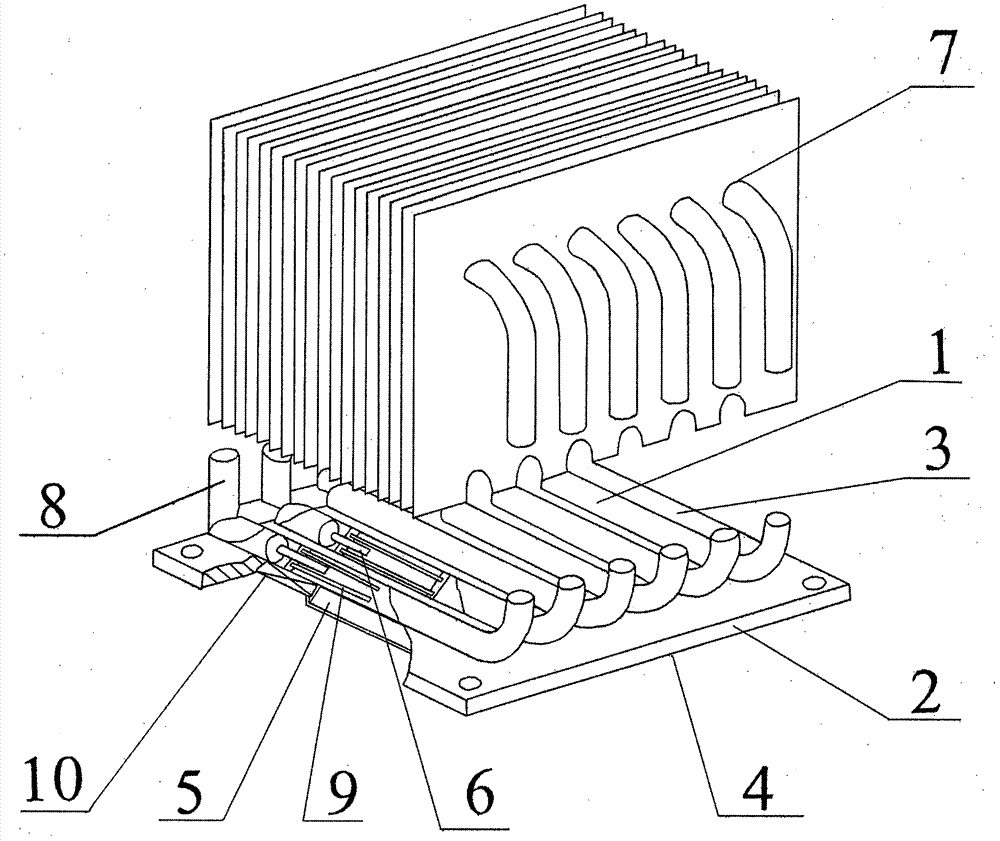

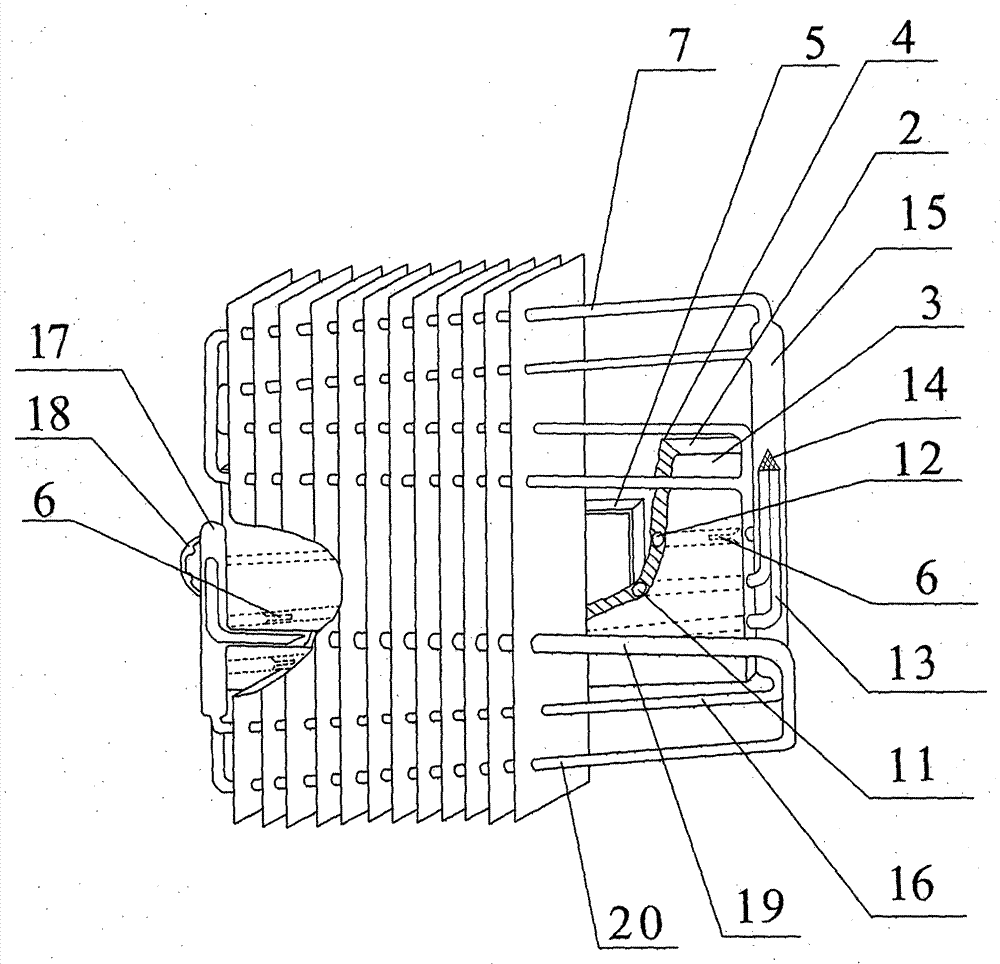

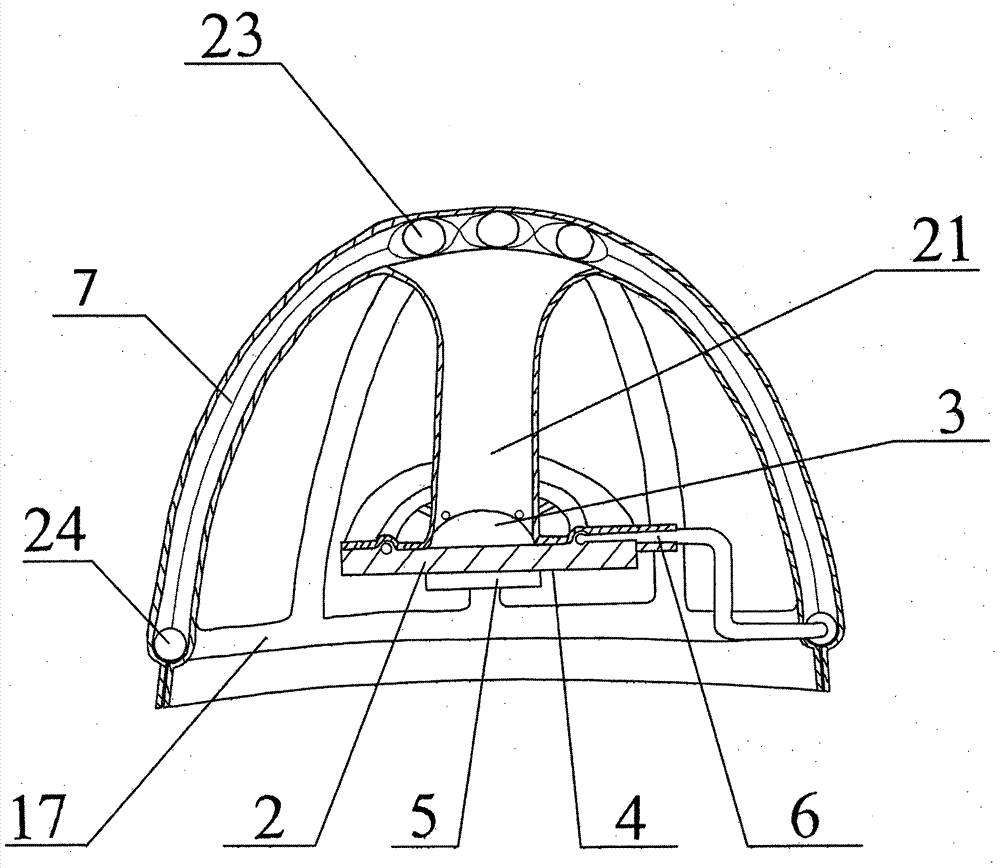

[0011] figure 1 For the first embodiment of the present invention, it is disassembled for the sake of clarity, and the upper part is vacated and a partial section is made at the bottom. The heat surface 4 is closely combined with the heat conduction surface of the semiconductor integrated module 5, and the fluid working medium enters the evaporation tube through the throttle valve 6 to form a heat exchange bottom plate. There are also heat dissipation fins on the heat dissipation surface of the bottom plate, interspersed in the heat dissipation fins The pipeline is the condensation pipe 7, which starts from the evaporation pipe and connects with the condensation pipe. The working medium in the pipeline adopts more than two kinds of mixed refrigerants with different boiling points prepared in a certain proportion. The formula is divided into three batches of start-up, easy-boiling and azeotropic. In the direct-exchange heat exchange base plate, the liquid formula working fluid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com