Battery core packaging film and battery

A battery cell and packaging film technology, applied in battery pack parts, battery box/jacket, battery box/cover material, etc., can solve the problems of destroying battery performance, difficult to meet battery needs, low connection strength, etc., and achieve guaranteed performance , Improve the service life and avoid the effect of performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

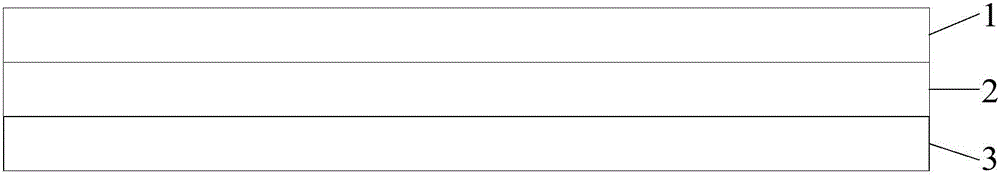

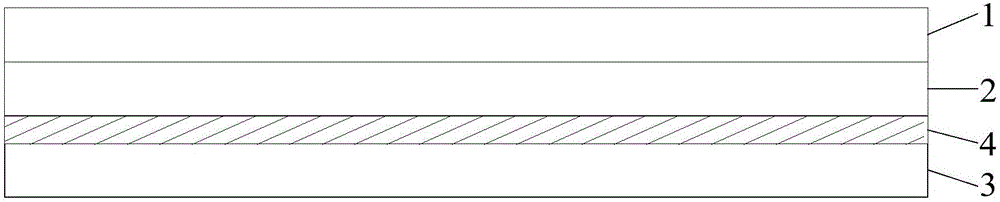

[0016] See figure 2 , figure 2 It is a schematic diagram of the structure of a battery core packaging film provided by the embodiment of the present invention. The battery core packaging film provided by the embodiment of the present invention includes an isolation layer 1, an aluminum foil layer 2 and a sealing layer 3 arranged in sequence, wherein the aluminum foil layer 2 and A protective layer 4 is arranged between the sealant layers 3, wherein the protective layer 4 is a plastic layer.

[0017] The thickness of the protective layer 4 is controlled to be between 0.01 and 10 microns, that is, greater than or equal to 0.01 microns to less than or equal to 10 microns, such as 0.01 microns, 0.1 microns, 3 microns, 8 microns, and so on. Preferably, the thickness of the protective layer 4 is controlled to be between 0.1 and 6 microns, that is, greater than or equal to 0.1 microns and less than or equal to 6 microns, such as 0.2 microns, 0.5 microns, 6 microns and so on.

[0018] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com