Live working phase spacing control device on equipotential wire

A technology of live operation and phase-to-phase distance, which is applied to overhead lines/cable equipment, etc., can solve the problems of inability to meet the requirements of the safety distance of the wires, and the sag of the phase wires becomes larger, so as to prevent the wires from falling off, safe in operation, and convenient in use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below through specific embodiments.

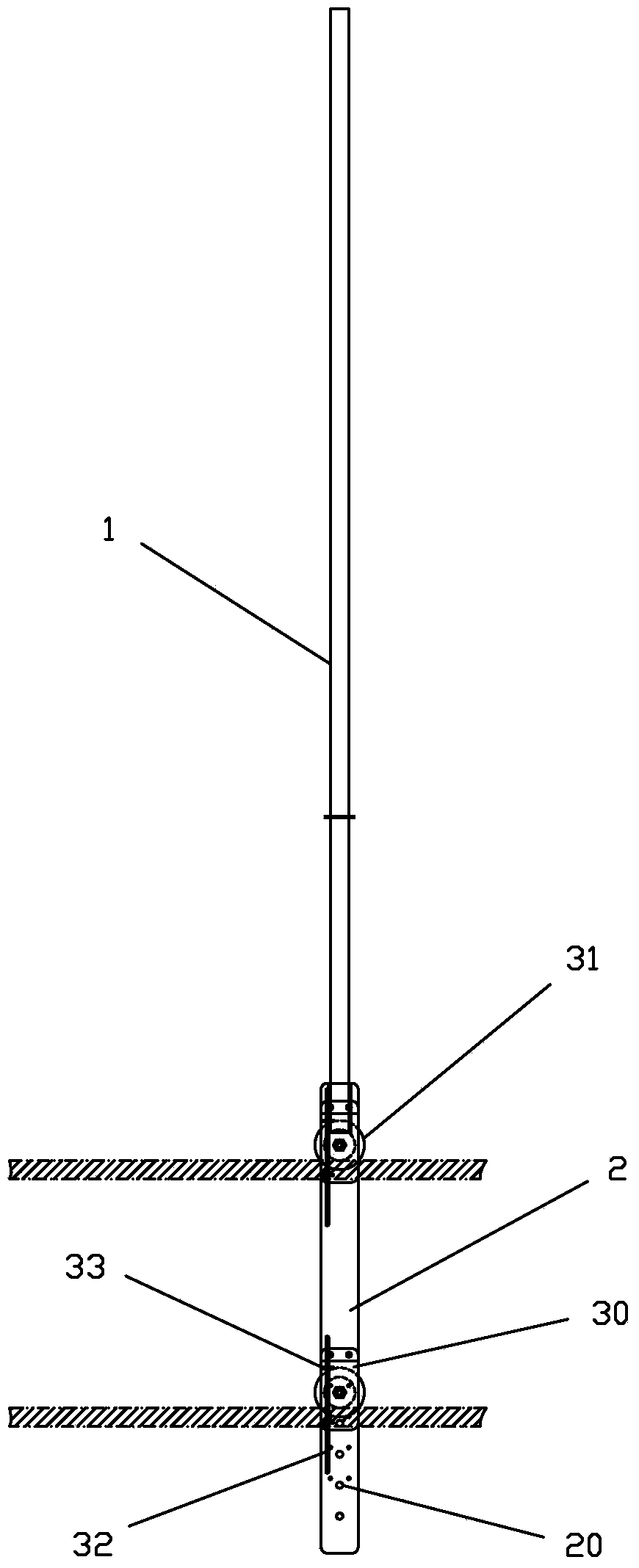

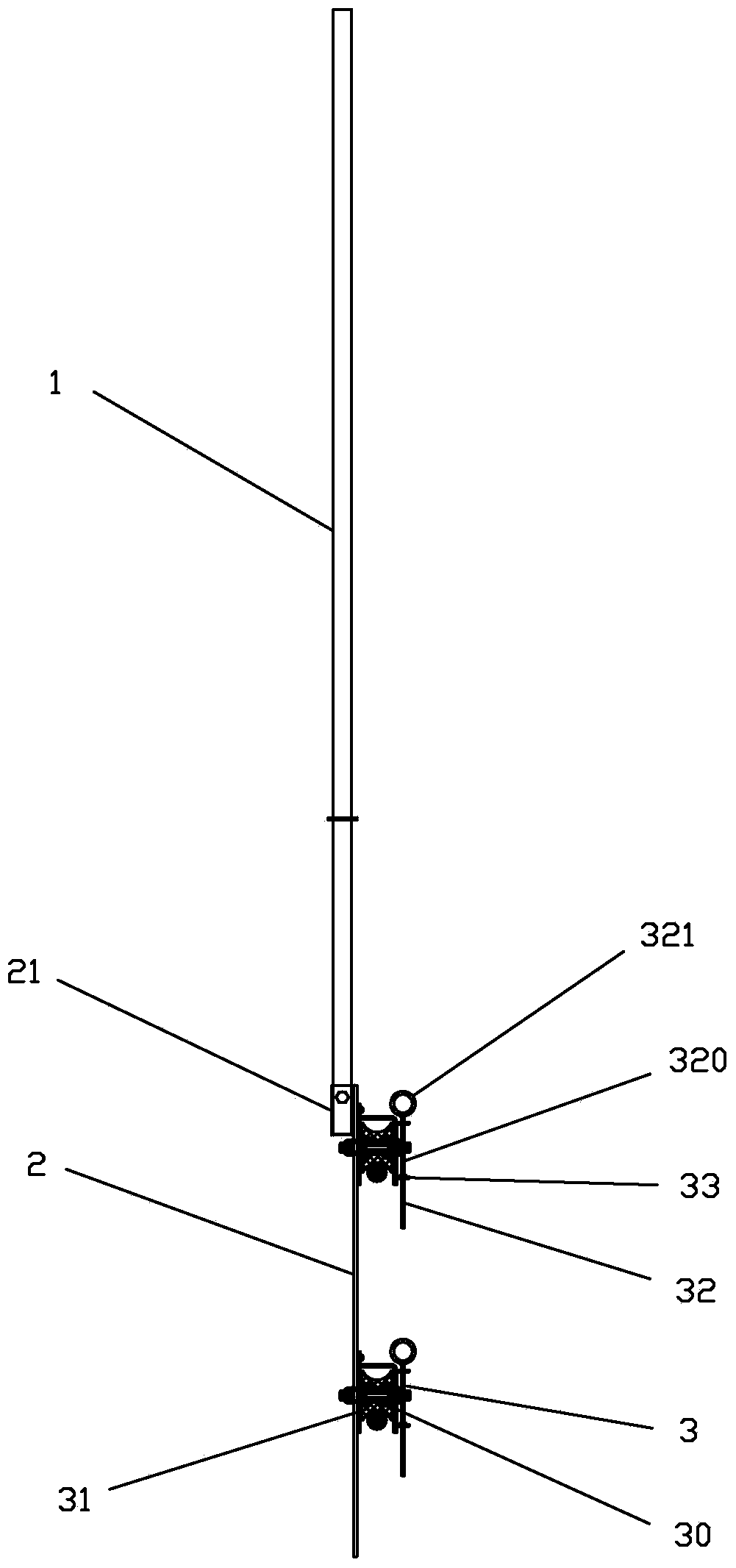

[0020] refer to figure 1 and figure 2 , a device for controlling the distance between phases of live work on equipotential conductors of the present invention is composed of a conductor fixing device connected to an insulating scale 1 .

[0021] The wire fixing device consists of an insulating connecting plate 2 and two wire fixing grooves 3 detachably installed on the insulating connecting plate 2 for fixing the lower wire sub-busbar. The wire fixing groove 3 consists of a mounting base 30, a The pulley 31 that is rotatably arranged in the mounting base 30 and a self-locking protection pin 32 that is detachably mounted on the mounting base 30 to prevent the wires from falling off are formed. A set of adjustment holes 20 are opened on the insulating connecting plate 2 to adjust the distance between the two wire fixing slots 3 . The mounting seat 30 is locked on the insulating conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com