Shoe glue spraying technology

A technology of glue spraying and technology, applied in the field of glue brushing process, which can solve problems such as glue flow and mass production constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Now, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

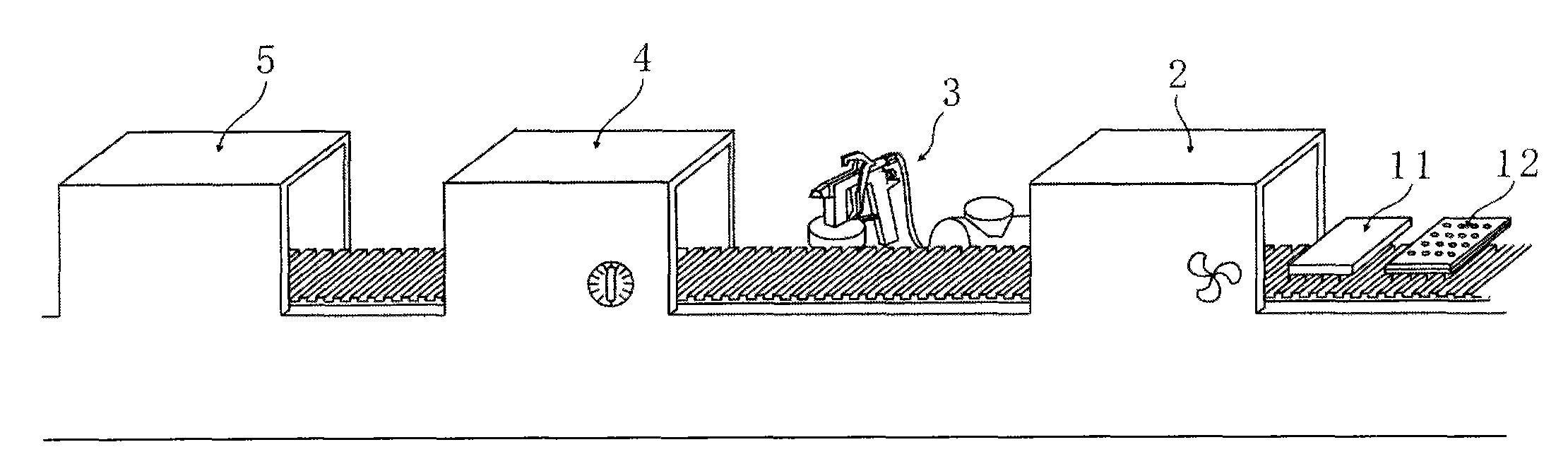

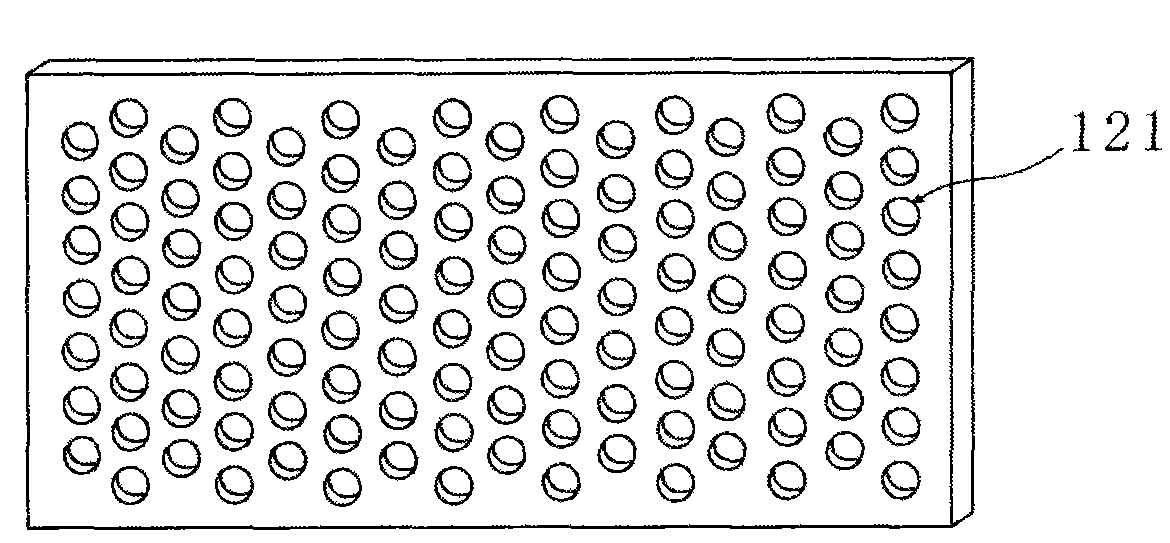

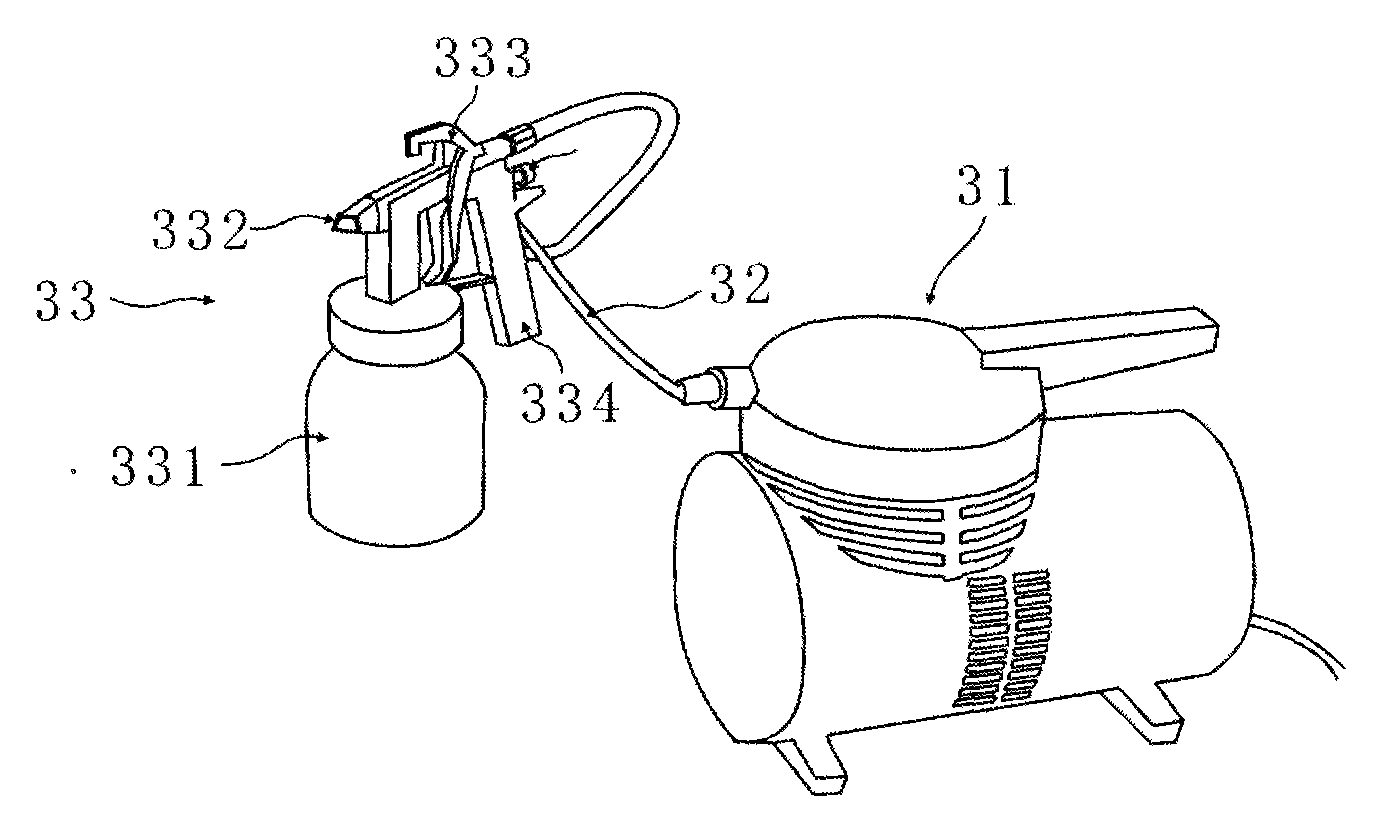

[0014] Such as figure 1 As shown, a footwear glue spraying technology includes the following steps: 1) component placement: lay one or more than one shoe upper parts on the glue spraying board 11 according to the nesting method, leaving a gap of 2mm-5mm between the parts , or fix the stretched side body on the glue spray rack, put it on the glue spray plate 11 corresponding to the matching sole, and place the shutter 12; 2) Dust removal: through the air jet device 2, the glue spray parts are dedusted as a whole, The speed is 8-10 seconds / m 2 ; 3) Glue spraying: hold a glue spraying device 3 or hang two glue spraying devices 3 to spray the glue spraying parts, the distance between the glue spraying device 3 and the glue spraying parts is 30cm-50cm, and the speed is 5-6 seconds / m 2 ;4) Drying: remove the shutter 12, put it into the drying box or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com