Automatic milling machine for die parting line of hard disk base

A hard disk base and parting line technology, applied in the field of machinery, can solve the problems of unfavorable occupational health of employees, high labor intensity, serious noise and dust, etc., to reduce occupational health hazards of employees, reduce labor costs, reduce noise and dust The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in further detail below in conjunction with accompanying drawing:

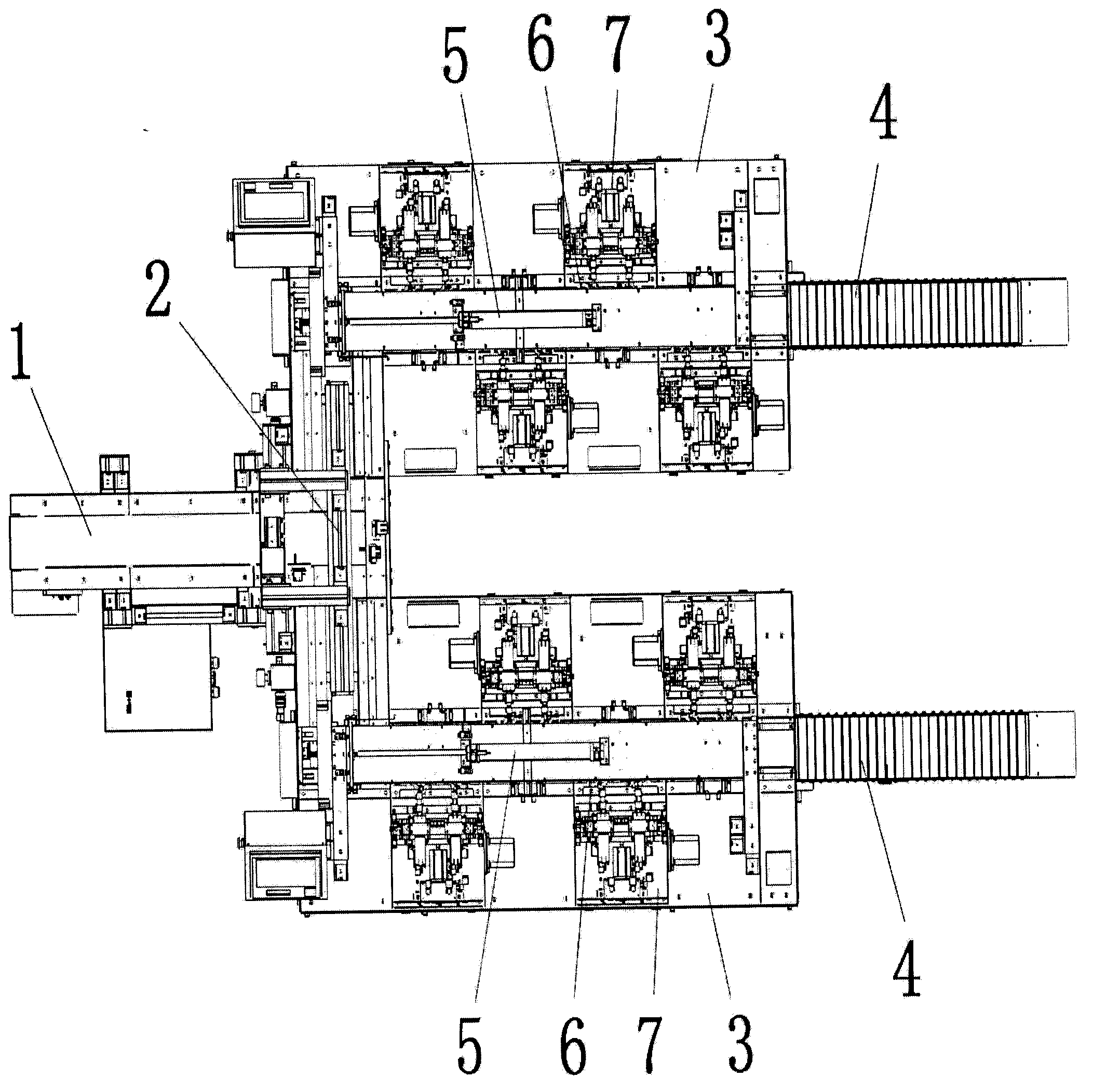

[0016] Such as figure 1 As shown, an automatic milling machine for a hard disk base parting line, including a base conveying device 1, a set of shunt components 2, two milling devices 3 and two sets of discharge guide rails 4, each milling device includes a set of bases Push assembly 5, four sets of base positioning fixtures 6, four sets of automatic milling servo systems 7. The conveying equipment 1 transports the base to the diversion assembly 2, and the diversion assembly 2 pushes the two adjacent bases to the two milling equipment 3 respectively, and two sets of push assemblies 5 push each base into eight sets of positioning fixtures 6, and each base is automatically positioned , After clamping, the corresponding eight sets of servo systems 7 start at the same time, return to the original position immediately after the milling action is completed, each positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com