A thin-walled aluminum alloy head flange ring seam laser welding fixture

A laser welding jig and aluminum alloy technology, which is applied in laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of weld seam precision not meeting welding requirements and large welding deformation, and achieve small welding deformation, low manufacturing cost, The effect of welding parameter stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

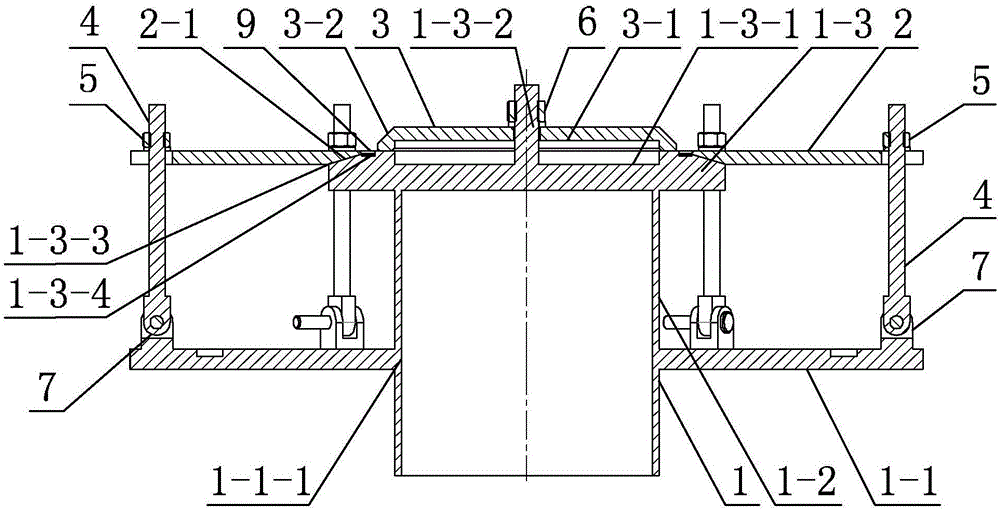

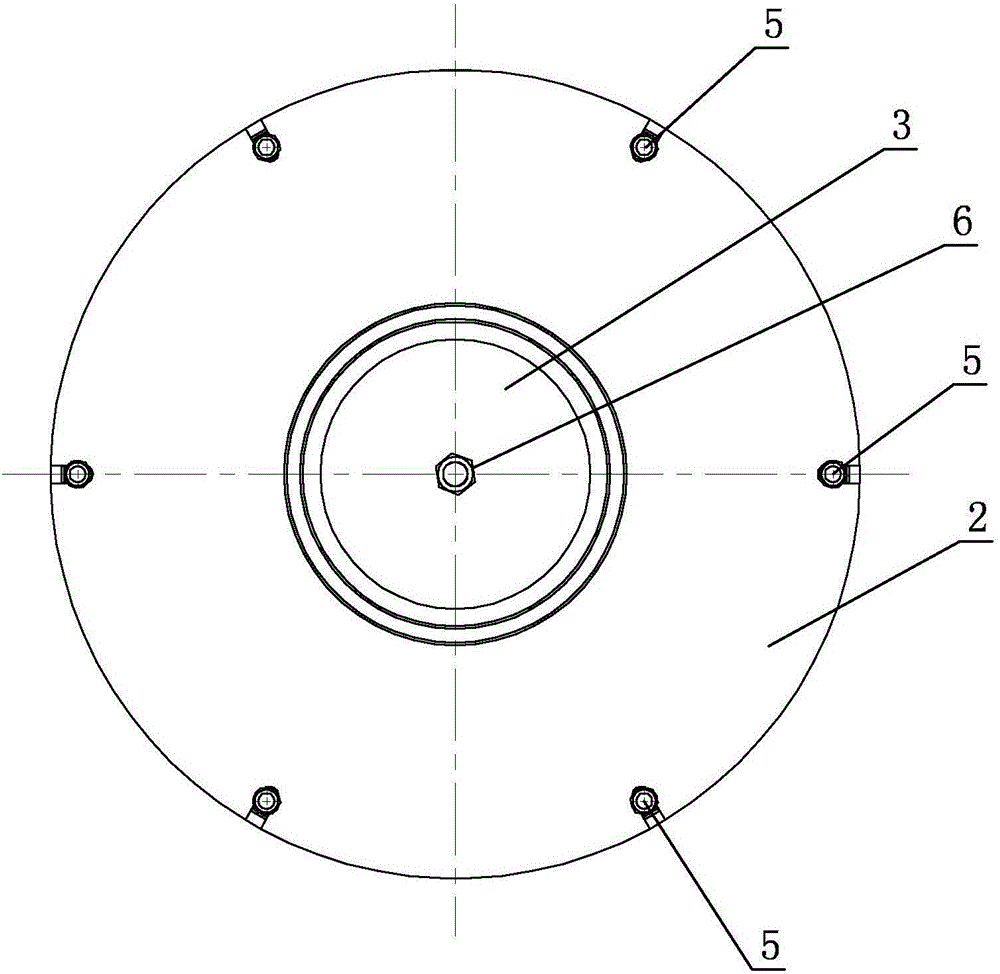

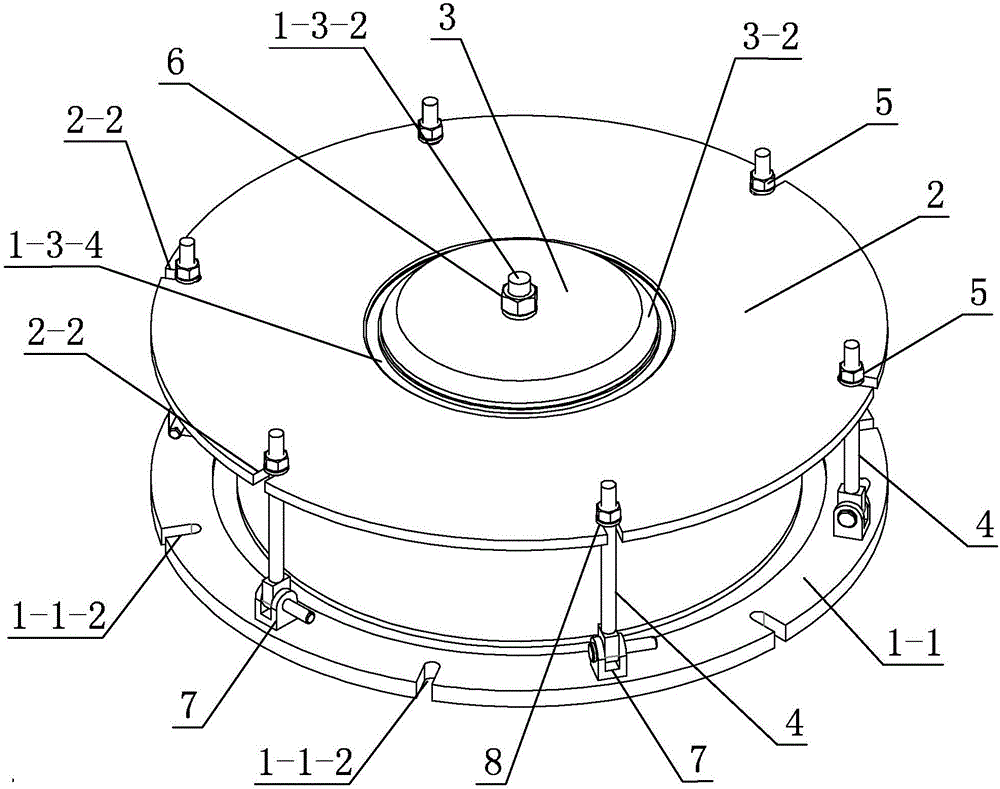

[0014] Specific implementation mode one: as Figure 1~4 As shown, the thin-walled aluminum alloy head flange circular seam laser welding fixture of this embodiment includes a bottom placenta 1, an outer pressure plate 2, an inner pressure plate 3, a first nut 6, a plurality of screws 4, a plurality of second Nut 5 and a plurality of hinge seats 7; the bottom placenta 1 includes a lower disc 1-1, a cylinder 1-2 and an inner pressure disc seat 1-3, and the lower disc 1-1 is processed with a first central through hole 1- 1-1, the lower disc 1-1 is fixedly set on the middle part of the outer wall of the cylinder 1-2, the inner pressure plate seat 1-3 is fixed on the upper end surface of the cylinder 1-2, the lower disc 1-1, The cylinder 1-2 and the inner pressure plate seat 1-3 are coaxially arranged and the three are integrated, and the upper end surface of the inner pressure plate seat 1-3 is processed with a first circular central groove 1-3-1, the first The upper end surface ...

specific Embodiment approach 2

[0016] Specific implementation mode two: as Figure 2-4 As shown, there are six screw rods 4 , second nuts 5 and hinge seats 7 in this embodiment. In this design, the number of screw rod 4, second nut 5 and hinge seat 7 is six, and the force of each second nut 5 is the same, so that the force on the head is uniform, and the welding deformation of the ring seam of the flange of the head can be controlled. . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: as figure 1 and image 3 As shown, in this embodiment, an annular groove 1-3-4 is processed on the inner pressure plate seat 1-3 along the circumferential direction, and the annular groove 1-3-4 is located at the annular gap 9 . Such a design is to prevent the occurrence of weld leakage caused by the serious sagging of the weld seam, thereby ensuring the formation of the weld seam. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com