Cement composition

A kind of cement composition, Portland cement technology, applied in the direction of cement production, etc., can solve the problem that the effect can not be effectively used and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

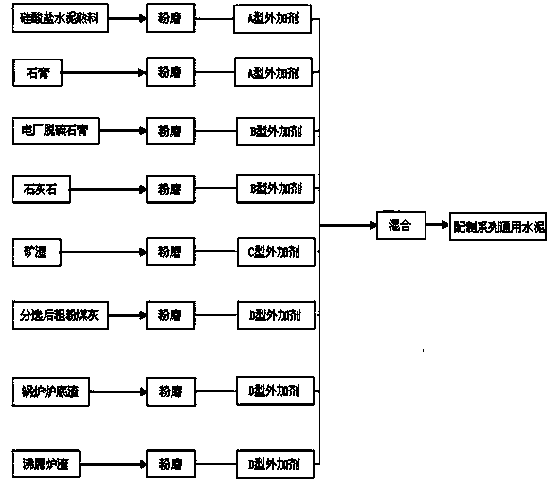

Image

Examples

Embodiment 1

[0033] Grind Portland cement clinker, gypsum, power plant desulfurization gypsum, limestone, slag, sorted coarse fly ash, boiler bottom slag and boiling slag, so that the specific surface area of the above components is as follows: silicate The specific surface area of cement clinker is 300m 2 / kg, the specific surface area of gypsum is 750m 2 / kg, the specific surface area of desulfurization gypsum in the power plant is 700m 2 / kg, the specific surface area of limestone is 900m 2 / kg, the specific surface area of slag is 470m 2 / kg, the specific surface area of coarse fly ash after sorting is 650m 2 / kg, the specific surface area of boiler bottom slag is 700m 2 / kg, the specific surface area of the boiling slag is 700m 2 / kg;

[0034] 2) Add 0.03wt% type A admixture to the ground Portland cement clinker and gypsum respectively, add 0.03wt% type B admixture to the ground power plant desulfurization gypsum and limestone respectively, add 0.03wt% type B a...

Embodiment 2

[0039] Grind Portland cement clinker, gypsum, power plant desulfurization gypsum, limestone, slag, sorted coarse fly ash, boiler bottom slag and boiling slag, so that the specific surface area of the above components is as follows: silicate The specific surface area of cement clinker is 400m 2 / kg, the specific surface area of gypsum is 700m 2 / kg, the specific surface area of desulfurization gypsum in the power plant is 750m 2 / kg, the specific surface area of limestone is 1000m 2 / kg, the specific surface area of slag is 450m 2 / kg, the specific surface area of coarse fly ash after sorting is 700m 2 / kg, the specific surface area of boiler bottom slag is 600m 2 / kg, the specific surface area of the boiling slag is 600m 2 / kg;

[0040] 2) Add 0.01wt% type A admixture to the ground Portland cement clinker and gypsum respectively, add 0.04wt% type B admixture to the ground power plant desulfurization gypsum and limestone respectively, and add 0.04wt% typ...

Embodiment 3

[0045] Grind Portland cement clinker, gypsum, power plant desulfurization gypsum, limestone, slag, sorted coarse fly ash, boiler bottom slag and boiling slag, so that the specific surface area of each of the above components is as follows: silicate The specific surface area of cement clinker is 350m 2 / kg, the specific surface area of gypsum is 800m 2 / kg, the specific surface area of desulfurization gypsum in the power plant is 800m 2 / kg, the specific surface area of limestone is 800m 2 / kg, the specific surface area of slag is 500m 2 / kg, the specific surface area of coarse fly ash after sorting is 600m 2 / kg, the specific surface area of boiler bottom slag is 650m 2 / kg, the specific surface area of the boiling slag is 650m 2 / kg;

[0046] 2) Add 0.05wt% type A admixture to the ground Portland cement clinker and gypsum respectively, add 0.01wt% type B admixture to the ground power plant desulfurization gypsum and limestone respectively, and add 0.01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com