Polyester knitted fabric and production method thereof

A silk-polyester needle and knitted fabric technology, which is applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of only striped patterns on the cloth surface, failure to improve silk weaving, complex and time-consuming engineering, etc. Achieve excellent moisture absorption and heat release performance, superior ventilation performance, and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

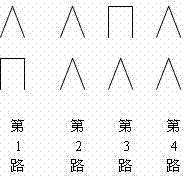

Method used

Image

Examples

Embodiment 1

[0034] The double-twisted yarn obtained above is woven on a 28G single-jersey knitting machine to obtain a weft plain knitted gray cloth. The obtained gray cloth is refined and degummed (95°C degumming, refining weight loss rate is 14%)-after intermediate setting (165°C), and then 0.5 One-bath dyeing of %owf disperse blue-0.5% owf acid blue dye (bath ratio 1:20), the dyeing temperature is 95°C, then the color is fixed and washed, and finally the finishing and setting (setting at 160°C) is carried out to obtain light blue silk-polyester knitting thing.

[0035] The grammage of gained knitted fabric is 130g / m 2 , a thickness of 0.5mm, and a silk content of 45%; according to the drape test, the number of corrugations of the knitted fabric is 10, and the drape coefficient is 15%. The obtained knitted fabric is suitable for use as close-fitting fabrics in spring and summer.

Embodiment 2

[0037] The double-twisted yarn obtained above is woven on a 28G single-jersey knitting machine to obtain a weft plain knitted gray cloth. The obtained gray cloth is refined and degummed (degummed at 95°C, and the weight loss rate of refining is 14%)-after setting in the middle (165°C), and then thickened. Dye the polyester false twisted textured yarn with black disperse dye at 98°C first, then restore and wash; then use acidic black dye to dye silk at 95°C, then fix and wash, and finally finish with water-absorbing resin , 165 ° C stereotypes to obtain thick black silk polyester knitted fabric.

[0038] The grammage of gained knitted fabric is 130g / m 2 , a thickness of 0.5mm, an L value of 15.6, and a silk content of 45%; according to the drape test, the number of corrugations of the knitted fabric is 10, and the drape coefficient is 15%. The obtained knitted fabric is suitable for use as close-fitting fabrics in spring and summer.

Embodiment 3

[0040] Feed the combined twisted yarn and 30D spandex obtained above into a 28G single-jersey knitting machine, and weave to obtain an elastic weft plain knitted gray fabric. After setting (165°C), the polyester false-twist textured yarn is dyed purple with disperse dyes at 95°C, and then the silk is dyed silver-gray with acid dyes at 95°C. After the setting is obtained, a "purple flash silver" elastic knitted fabric is obtained.

[0041] The grammage of the obtained knitted fabric is 150g / ㎡, the thickness is 0.5mm, and the silk content is 42%. According to the drape test, the number of corrugations of the knitted fabric is 12, and the drape coefficient is 10%. The obtained knitted fabric is suitable for use as close-fitting fabrics in spring and summer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com