Safety paper, safety paper manufacturing method and movement synchronizing device for strip material

A manufacturing method and paper technology, which are applied in papermaking, patterned paper, papermaking machines, etc., can solve the problem that the rotary screen cannot be reused, and achieve the effects of enhancing anti-counterfeiting effect, improving production efficiency and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

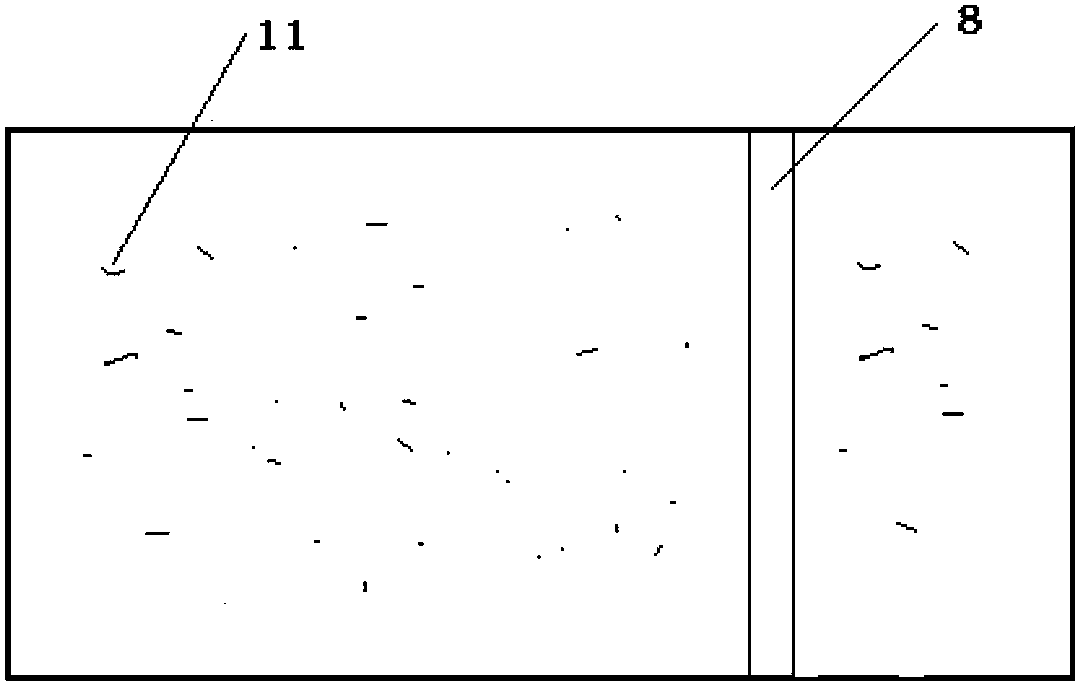

[0031] A security paper (such as image 3 shown), containing a white watermark pattern8 on the surface of the security paper.

[0032] The safety paper in this embodiment contains the following raw materials in dry weight parts: 4 parts of cotton fiber and 1 part of anti-counterfeiting fiber 11; the anti-counterfeiting fiber used in this embodiment is colorless fluorescent fiber, and the papermaking fiber used is cotton fiber after beating; In this example, the strip material is a solid, straight edge, made of PU material.

[0033] A method of manufacturing security paper:

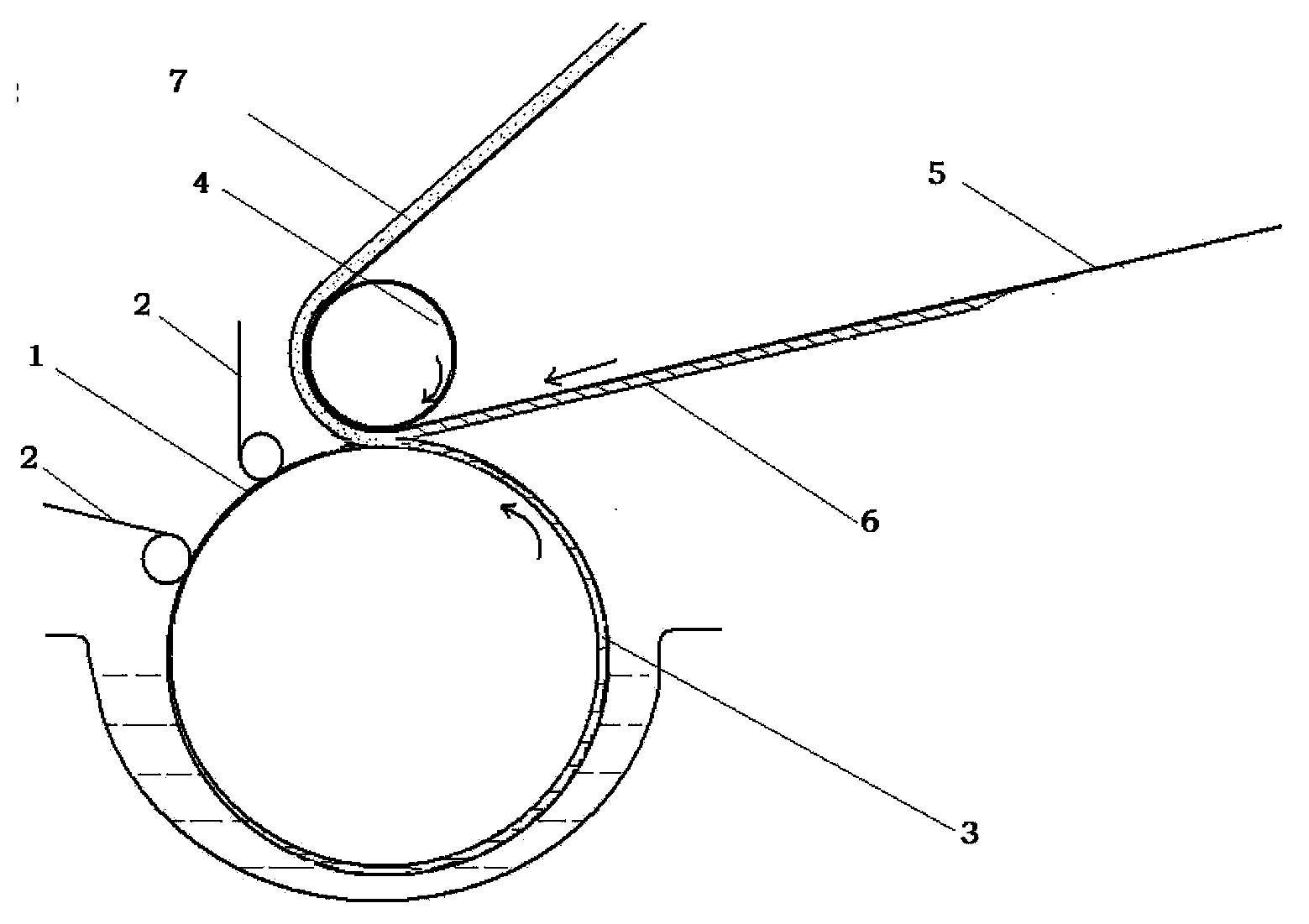

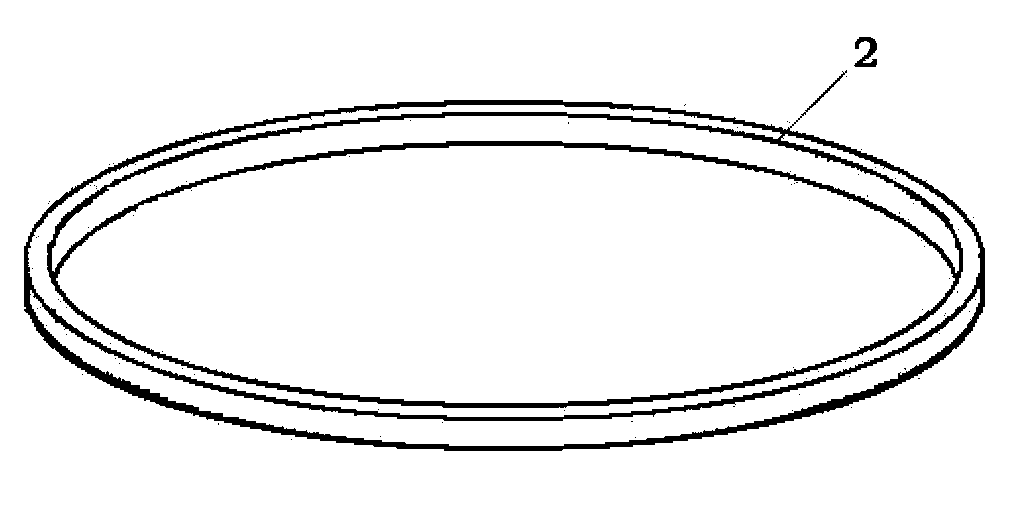

[0034] Step 1. Install the belt-shaped material operation synchronization device, which includes a drive device composed of a motor and a transmission system and a pulley wound with a belt-shaped material. The belt-shaped material is driven by a motor, and the motor controls the movement of the belt-shaped material and the cylinder synchronous operation;

[0035] Step 2. adopting traditional rotary scre...

Embodiment 2

[0039] A security paper containing a white watermark pattern 8 on the surface of the security paper.

[0040] The safety paper in this embodiment contains the following raw materials in dry weight parts: 4 parts of cotton fiber and 1 part of anti-counterfeiting fiber 11; the anti-counterfeiting fiber used in this embodiment is colorless fluorescent fiber, and the papermaking fiber used is cotton fiber after beating; In this example, the strip-shaped material is solid, with folded edges, and is made of PA containing metal fibers.

[0041] A method of manufacturing security paper:

[0042]Step 1. Install the belt-shaped material operation synchronization device, which includes a drive device composed of a motor and a transmission system and a pulley wound with a belt-shaped material. The belt-shaped material is driven by a motor, and the motor controls the movement of the belt-shaped material and the cylinder synchronous operation;

[0043] Step 2. Using a cylinder paper machi...

Embodiment 3

[0048] A security paper containing a white watermark pattern 8 on the surface of the security paper.

[0049] The safety paper of this embodiment contains the following raw materials in dry weight parts: 10 parts of flax fiber and 1 part of anti-counterfeiting fiber 11; the papermaking fiber used is beaten flax fiber; anti-counterfeiting pigment is used as one of the anti-counterfeiting materials and added to the slurry for papermaking ; In this example, the strip material is a strip material containing a hollow area 13, and the shape of the hollow area presents on the side surface is an irregular geometric figure and a regular geometric figure, and the edge of the strip material is a curve, and the material used is an alloy Copper material is used to make strip material.

[0050] A method of manufacturing security paper:

[0051] Step 1. Install the belt-shaped material operation synchronization device, which includes a drive device composed of a motor and a transmission sys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com