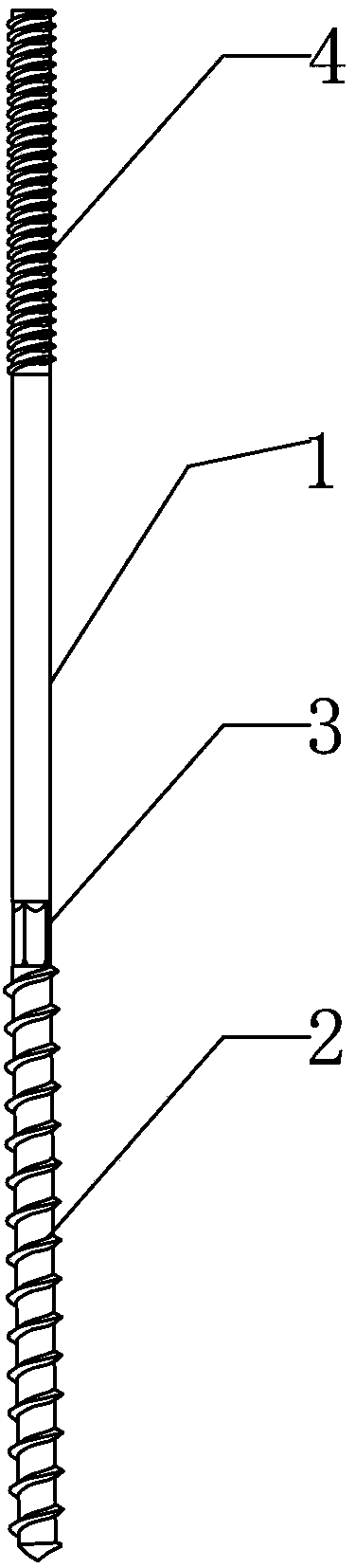

Double tooth screw

A screw and thread technology, applied in the field of double tooth screws, can solve the problems of destructive damage, inconvenient installation and disassembly, etc., and achieve the effect of stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] In this embodiment, a double-thread screw includes a stainless steel or carbon steel rod body 1. The front end of the rod body 1 is provided with a wood thread 2, and the end of the wood thread 2 is connected to the rod body to be an external hexagon 3; the rear end of the rod body 1 is provided with a machine thread 4; There is an octagonal star hole in the cross section of the threaded tail of the rod body 1; use a wrench to turn the hexagonal part of the screw rod to drill the wood thread into the connecting object to fix it, and punch a hole equivalent to the diameter of the screw rod. , Pass through the threaded part of the end of the screw, use a nut to hide and fix the screw in the object to be connected. The outer end of the hole end of the object has a slightly wider diameter to accommodate the nut, so that the nut is hidden in the object at the same time; when it needs to be removed, use a screw The knife tool acts on the octagonal star at the end to unscrew the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com