Range hood, and method and system for adjusting constant air volume of range hood

A technology of constant air volume and adjustment method, applied in the direction of oil fume removal, heating mode, household heating, etc., can solve the problem of self-adaptive adjustment of output constant air volume, etc., and achieve the effect of ensuring effect and constant output air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

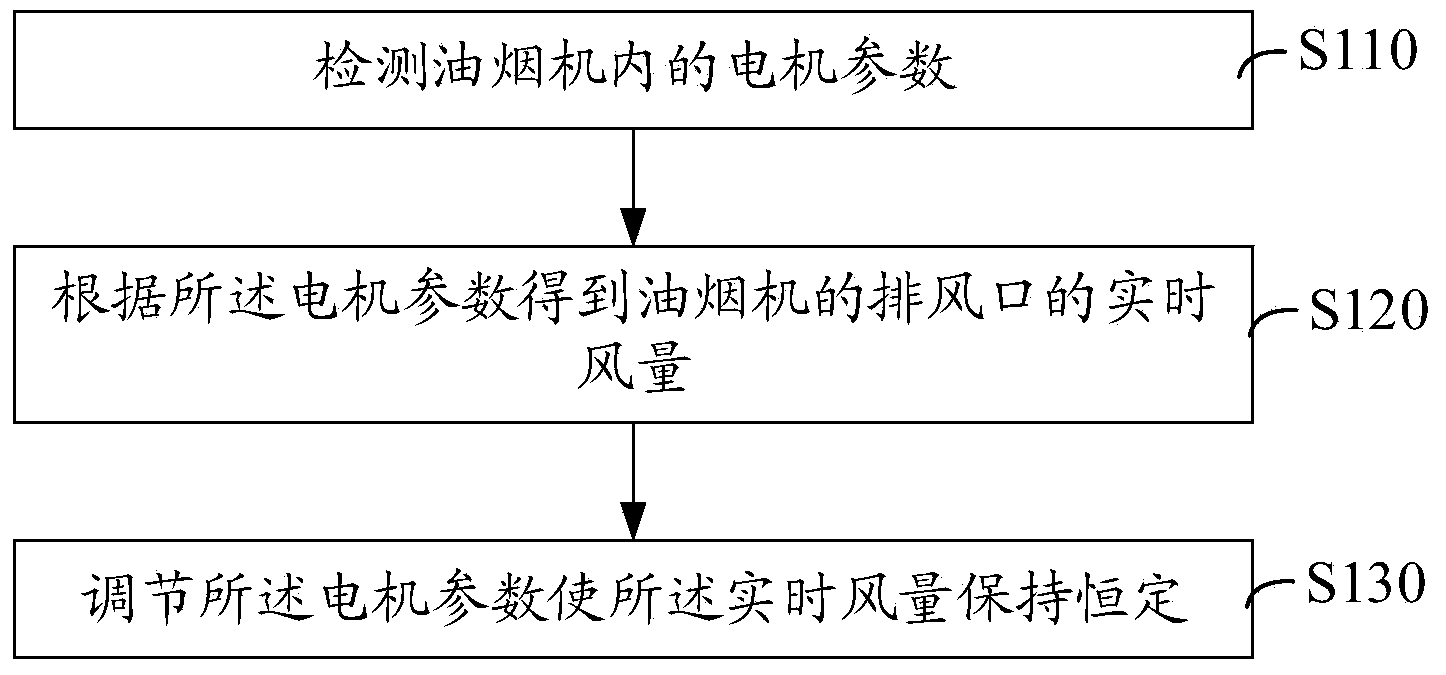

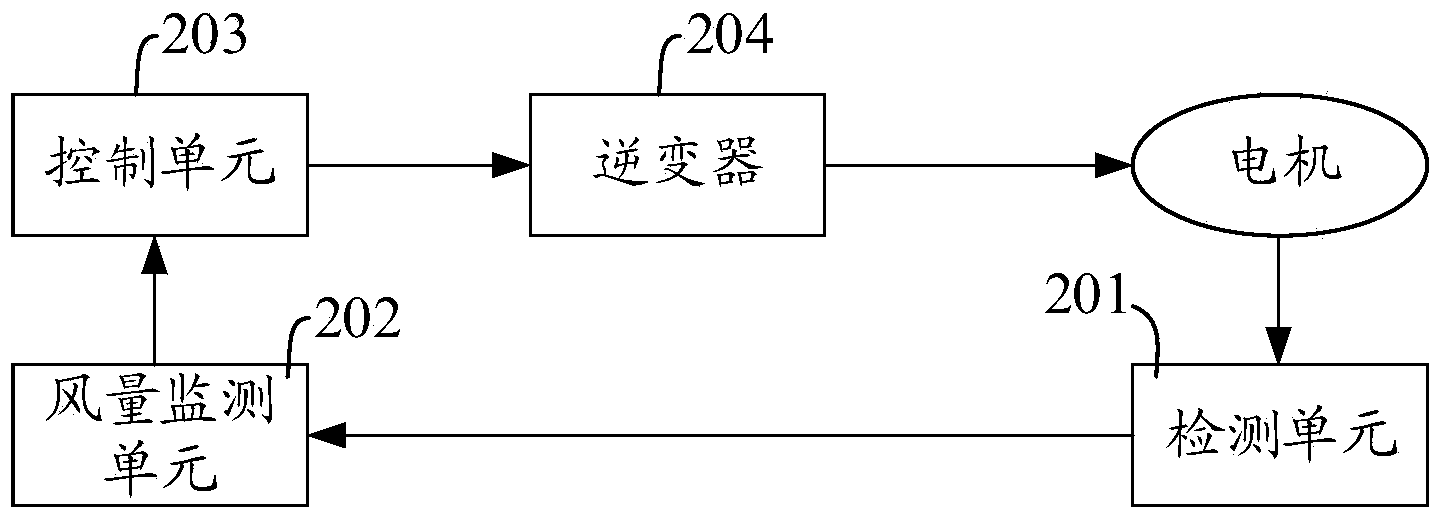

Method used

Image

Examples

Embodiment 1

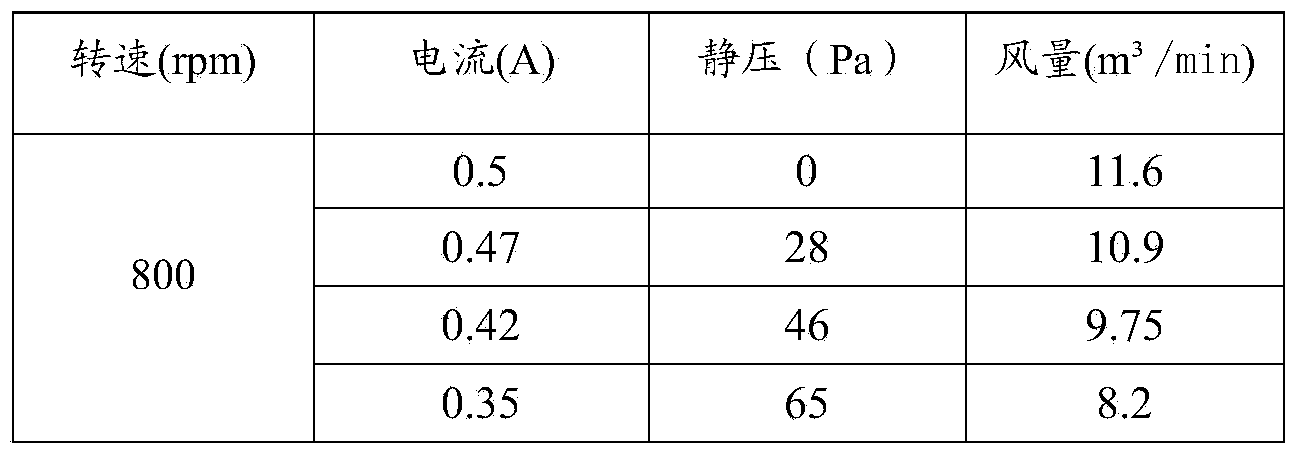

[0027] Embodiment one: only adopt the operating current I in the operating parameters of the motor to establish the air volume model:

[0028] Real-time air volume Q=C0×I+C1×I 2 +C2×I 3 ;

[0029] In the above formula, I is the operating current of the motor (that is, the bus current), and the preset parameters C0, C1, and C2 can be obtained by fitting the air volume and operating current I under different static pressures.

Embodiment 2

[0030] Embodiment 2: Using the motor running speed n and running current I to establish an air volume model:

[0031] Real-time air volume Q=C0×I+C1×n×I;

[0032] Or Q=C0×n+C1×I 2 +C2×I 2 ×n 2 +C3×n 3 ;

[0033] In the above formula, I is the operating current of the motor, n is the operating speed of the motor, and the preset parameters C0, C1, C2, and C3 can be obtained by fitting the air volume and operating parameter data under different static pressures.

Embodiment 3

[0034] Embodiment 3: Only the operating speed n, operating voltage u among the operating parameters of the motor and the winding resistance R, winding inductance L, winding pole pair number p, and back EMF coefficient ke of the motor body parameters are used to establish the air volume model.

[0035] by the formula: u 2 =(k e ×n+ωL d i d ) 2 +(ωL q i q ) 2 ;

[0036] ω=2πpn / 60;

[0037] Among them, among the commonly used surface mount motors: L q = L; L q is the q-axis inductance; L d is the d-axis inductance; i d is the d-axis current; i q is the q-axis current; ω is the angular velocity of the motor.

[0038] In vector control i d =0 control mode can get:

[0039] I=(i 2 d + i 2 q ) 1 / 2 = i q ;

[0040] u 2 =(k e ×n) 2 +(ωL q i q ) 2 ;

[0041] I=g(u,n,L,R)=(u 2 -(k e ×n) 2 ) / (ωL)=(u 2 -(k e ×n) 2 ) / (2πpnL / 60);

[0042] The air volume model formula can be obtained:

[0043] Q=f(u,n,L,R)=C0×g 2 (u,n,L,R)+C1×g 3 (u,n,L,R);

[0044] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com