Adsorption roller for continuous printed matter detection and adjusting method for conveyed printed matter

A printed matter and roller technology, which is applied in the field of adsorption rollers for continuous detection of printed matter, can solve problems such as unstable paper angles, difficulty in extinction monitoring, and unstable measured objects, so as to prevent inconsistent states of scanning parts and ensure consistency and stability. performance, improving quality inspection reliability and quality inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

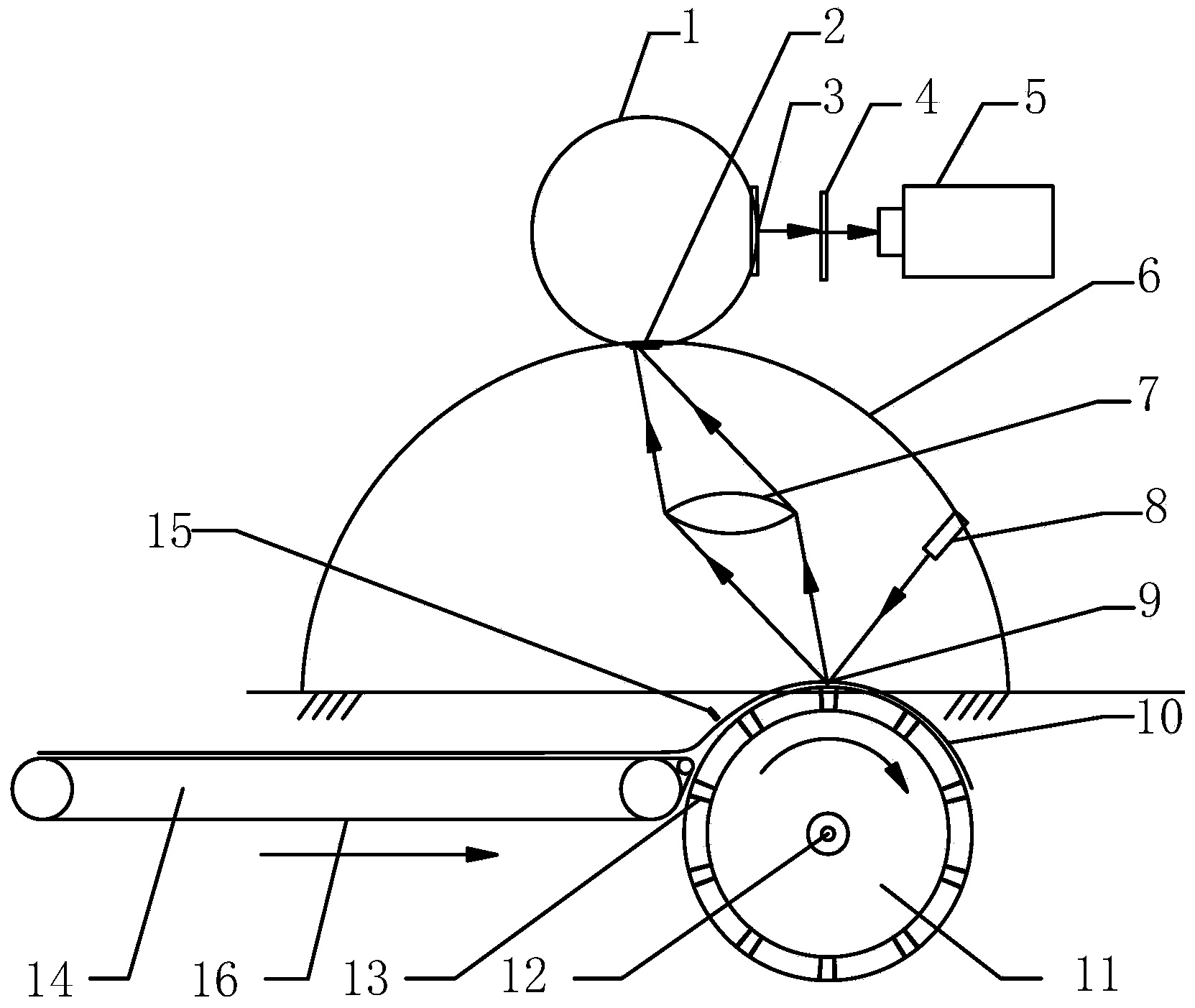

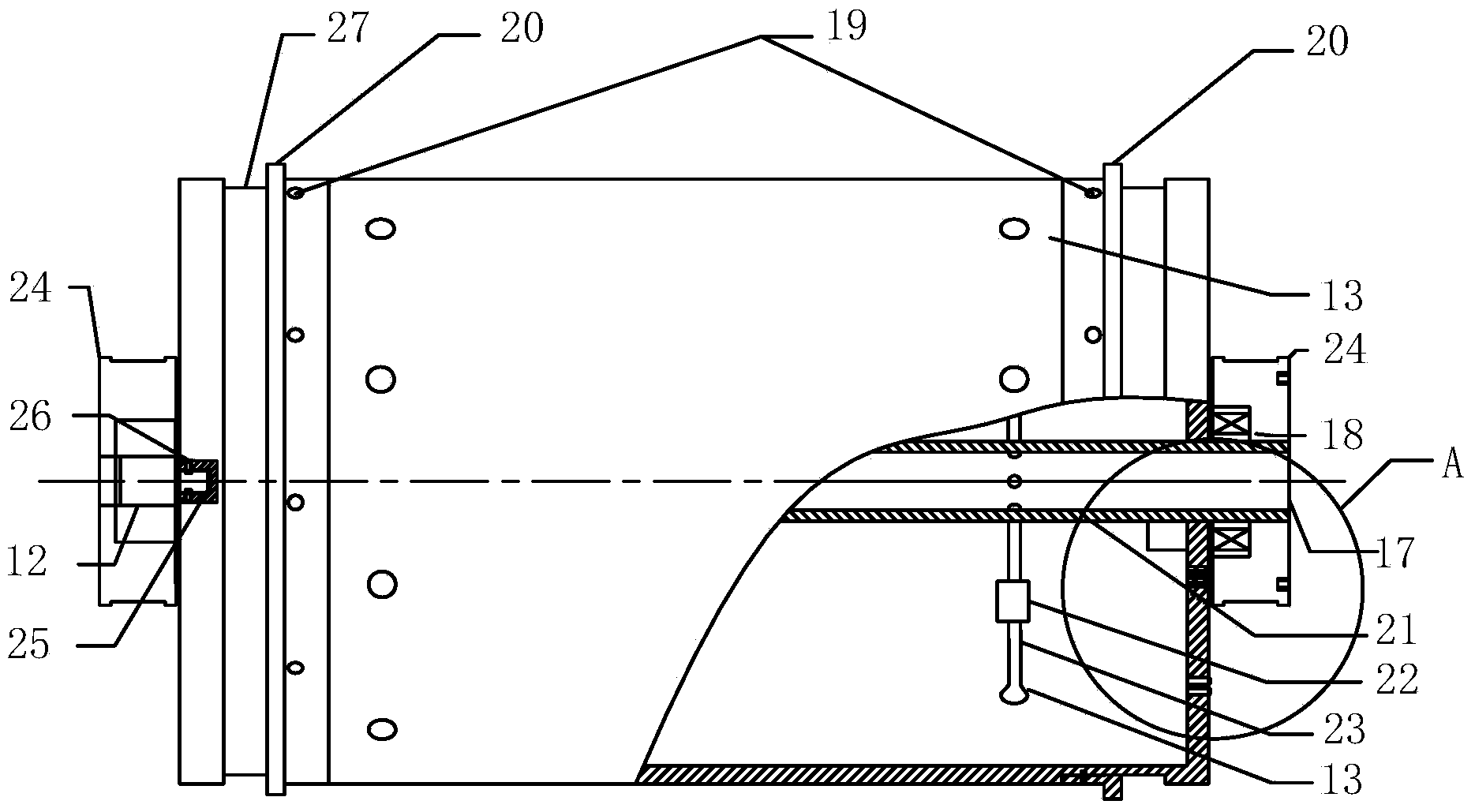

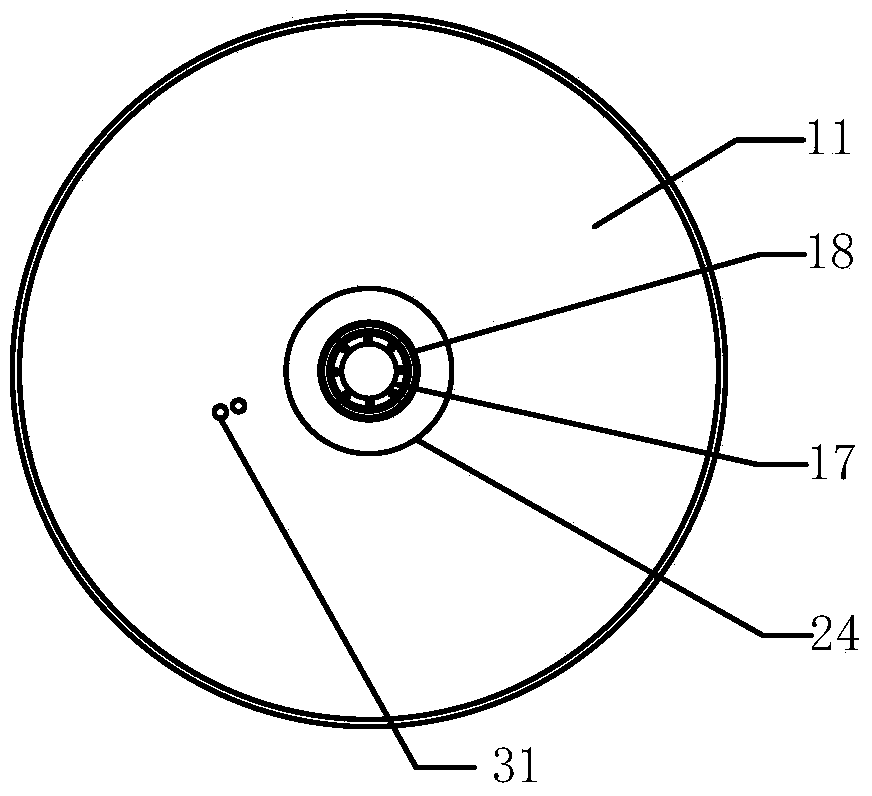

[0025] The invention is applied to the extinction detection device for continuously identifying the hue of laser printing. In order to realize continuous laser printing quality inspection, sufficient diffuse light and direct light source are provided in the diffuse hemisphere. At the same time, in order to ensure the consistency of the detection status of the printed matter, use The printed matter that is fixed and tensioned by the adsorption roller ensures the consistency and stability of the scanned image, and prevents the inconsistent state, inaccurate position, surface wrinkles, vibration and deflection of the printed matter during the batch continuous inspection process. The resulting damage and other problems have greatly improved the image reduction and clarity of the laser printed part and the non-laser printed part.

[0026] The following specifically introduces the extinction detection device corresponding to the present invention for continuously identifying the hue of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com