Electrical equipment defect detection and maintenance method

A technology for electrical equipment and defect detection, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of low cost, high cost, low efficiency, etc., and achieve the effect of improving efficiency, improving accuracy and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

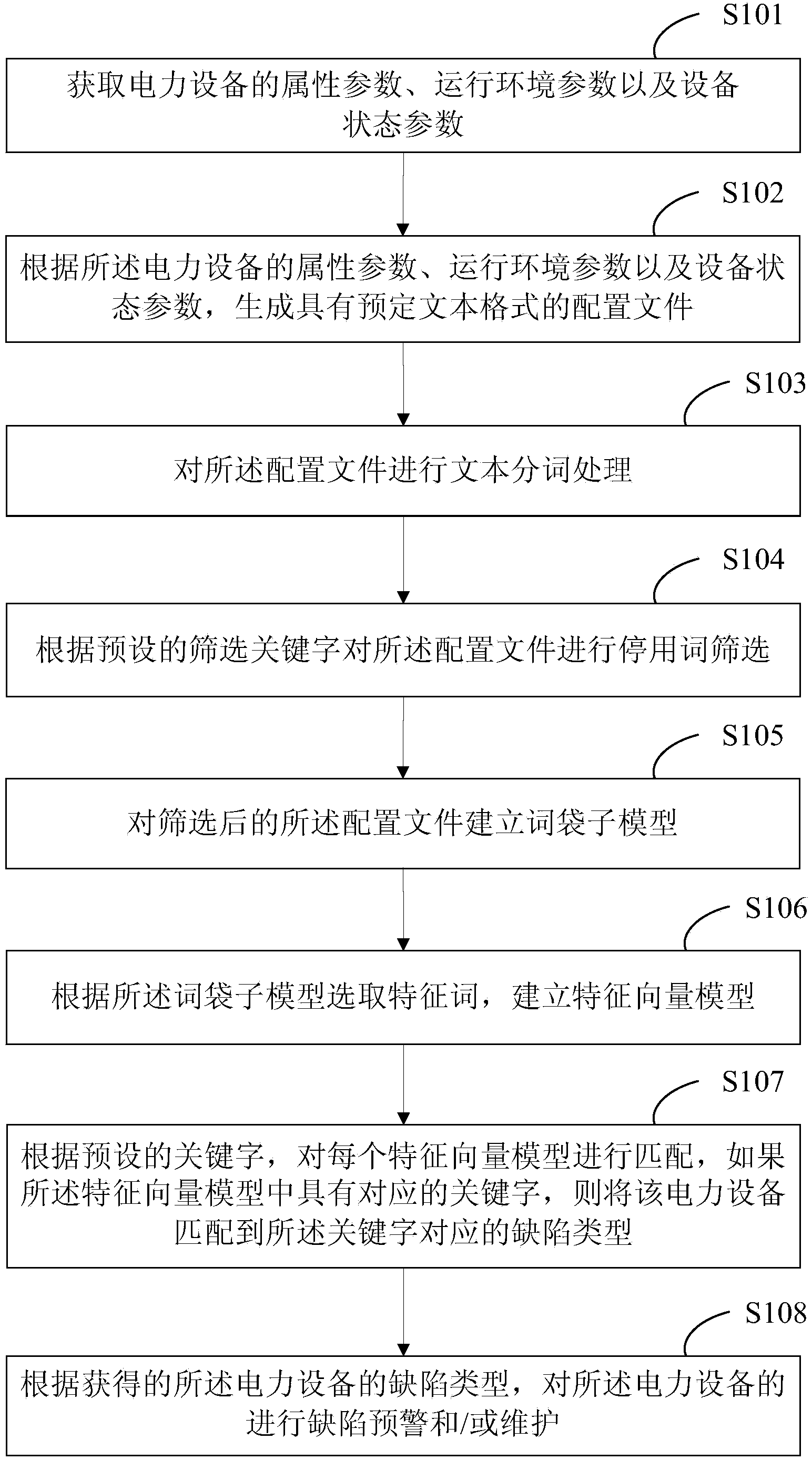

[0020] see figure 1 , figure 1 It is a schematic flow chart of the electric equipment defect detection and maintenance method of the present invention.

[0021] The method for detecting and maintaining defects in electrical equipment includes the following steps:

[0022] S101, acquiring attribute parameters, operating environment parameters and device status parameters of the electric equipment;

[0023] S102. Generate a configuration file in a predetermined text format according to the attribute parameters, operating environment parameters, and device status parameters of the electric device;

[0024] S103, performing text segmentation processing on the configuration file;

[0025] S104, performing stop word filtering on the configuration file according to preset filtering keywords;

[0026] S105, establishing a bag-of-words model for the configuration file after screening;

[0027] S106, selecting feature words according to the bag-of-words model, and establishing a fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com