Acceleration sensor

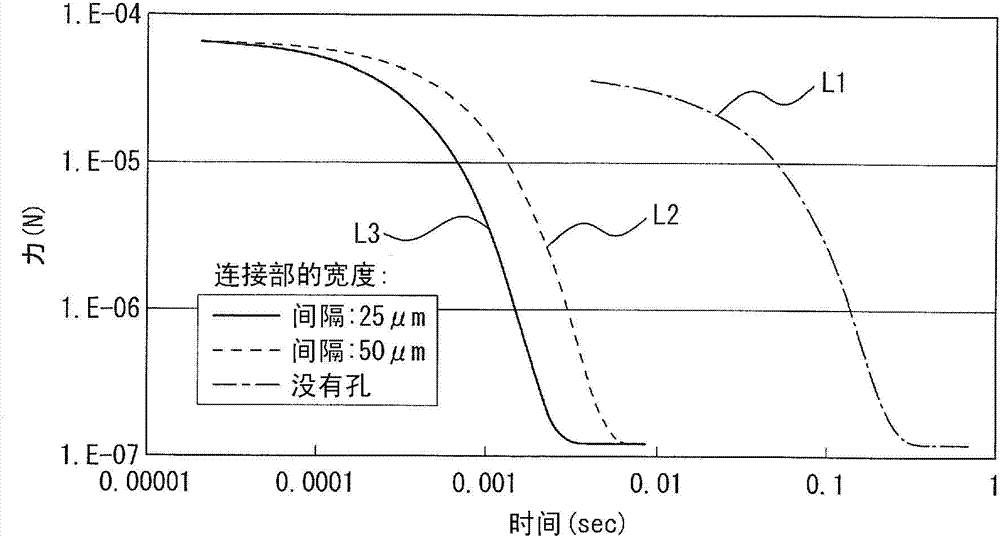

An acceleration sensor and area technology, which is applied in the measurement of acceleration, multi-dimensional acceleration measurement, speed/acceleration/impact measurement, etc., can solve the problem of inability to obtain a large air damping effect, and achieve the effect of reducing air damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described below based on the drawings.

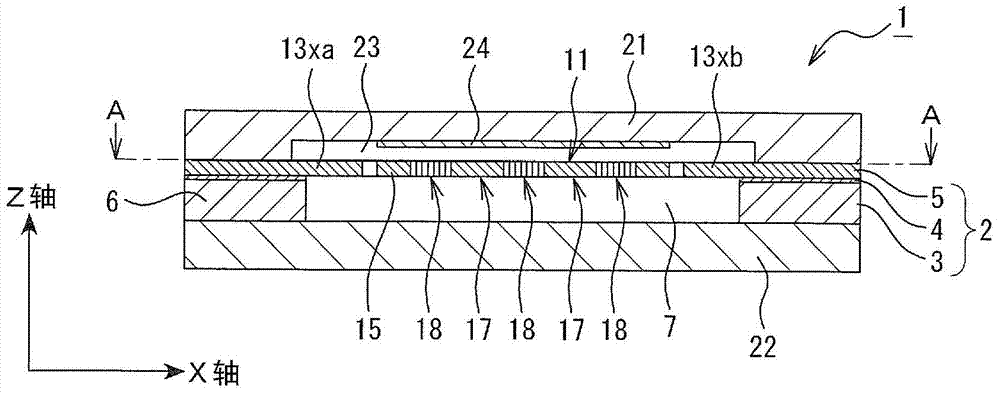

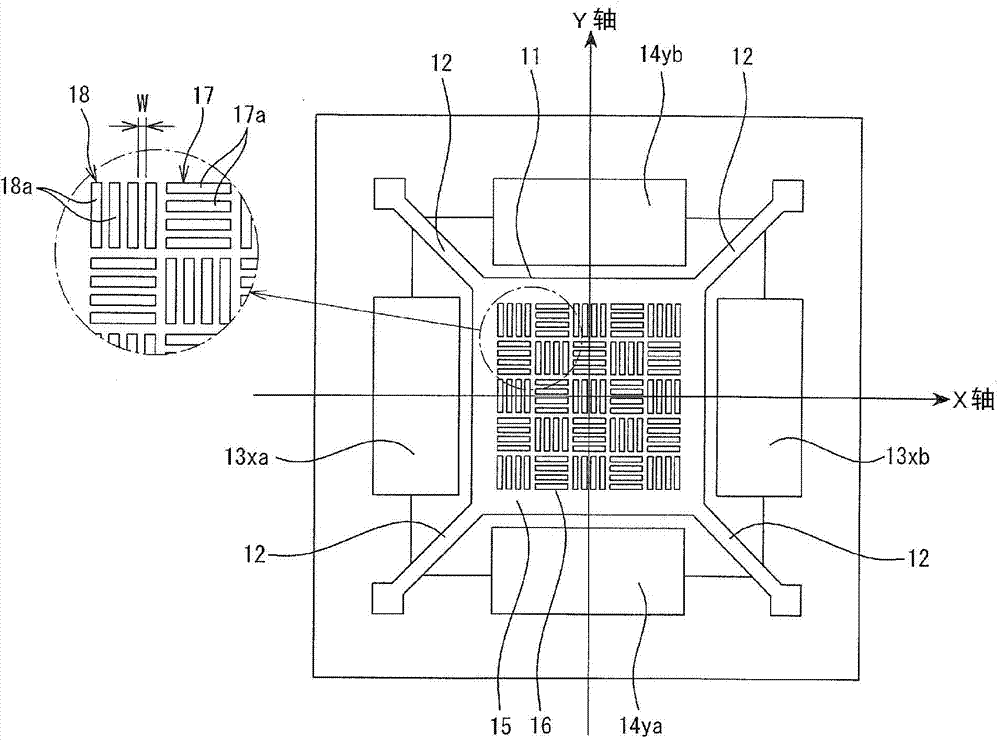

[0026] figure 1 is a sectional view showing an example of an acceleration sensor according to the present invention, figure 2 yes figure 1 End view of the A-A line.

[0027] In the figure, 1 is an acceleration sensor, and the acceleration sensor 1 is formed on an SOI (Silicon On Insulator: silicon on insulator) substrate 2 . The SOI substrate 2 is composed of an underlying silicon support layer 3 , a silicon oxide layer 4 formed on the silicon support layer 3 , and an active silicon layer 5 formed on the silicon oxide layer 4 .

[0028] In addition, the square frame-shaped portion 6 on the outer peripheral side of the silicon supporting layer 3 and the silicon oxide layer 4 is left, and the central portion is removed by etching to form a space portion 7 .

[0029] On the other hand, for the active silicon layer 5 on the upper part, for example, use anisotropic dry etching to remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com