Air cushion type furnace roller, position closed-loop control system based on furnace roller and application thereof

A closed-loop control, air-cushion technology, used in furnace control devices, furnaces, furnace components, etc., can solve the problems of easy to scratch the strip, unstable air cushion pressure, and the thickness of the air cushion should not be too small, so as to reduce the moment of inertia and damping. , the effect of reducing scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

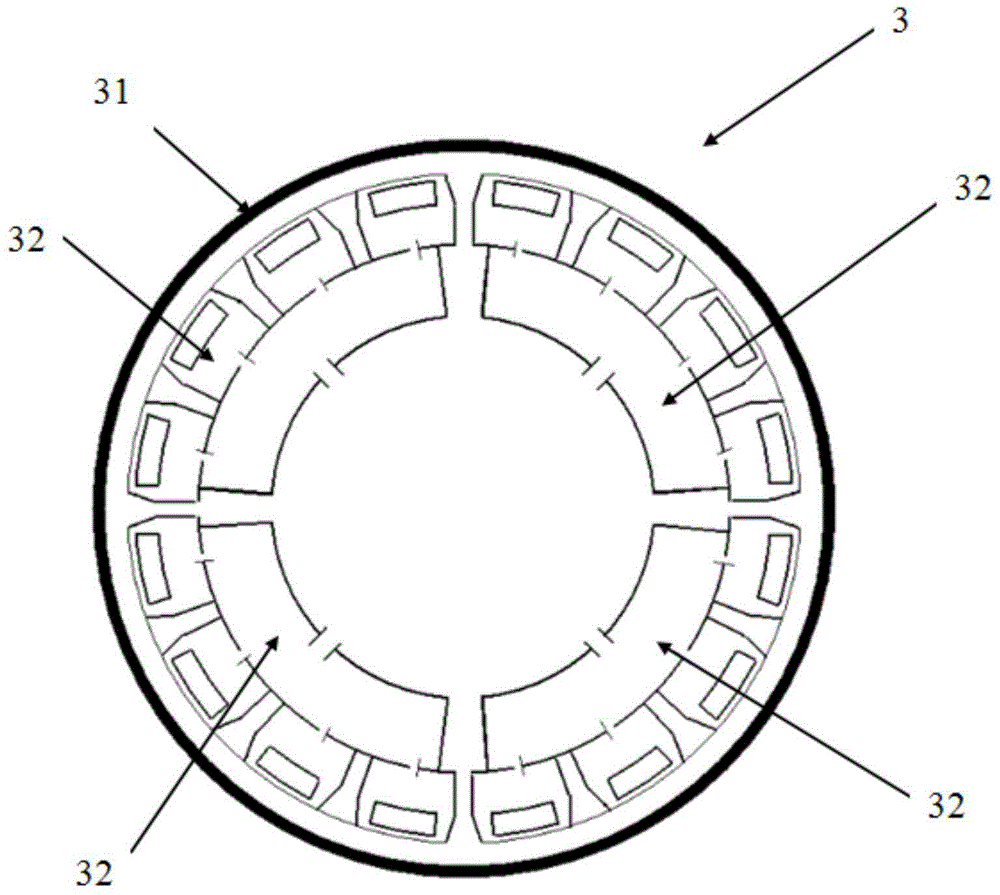

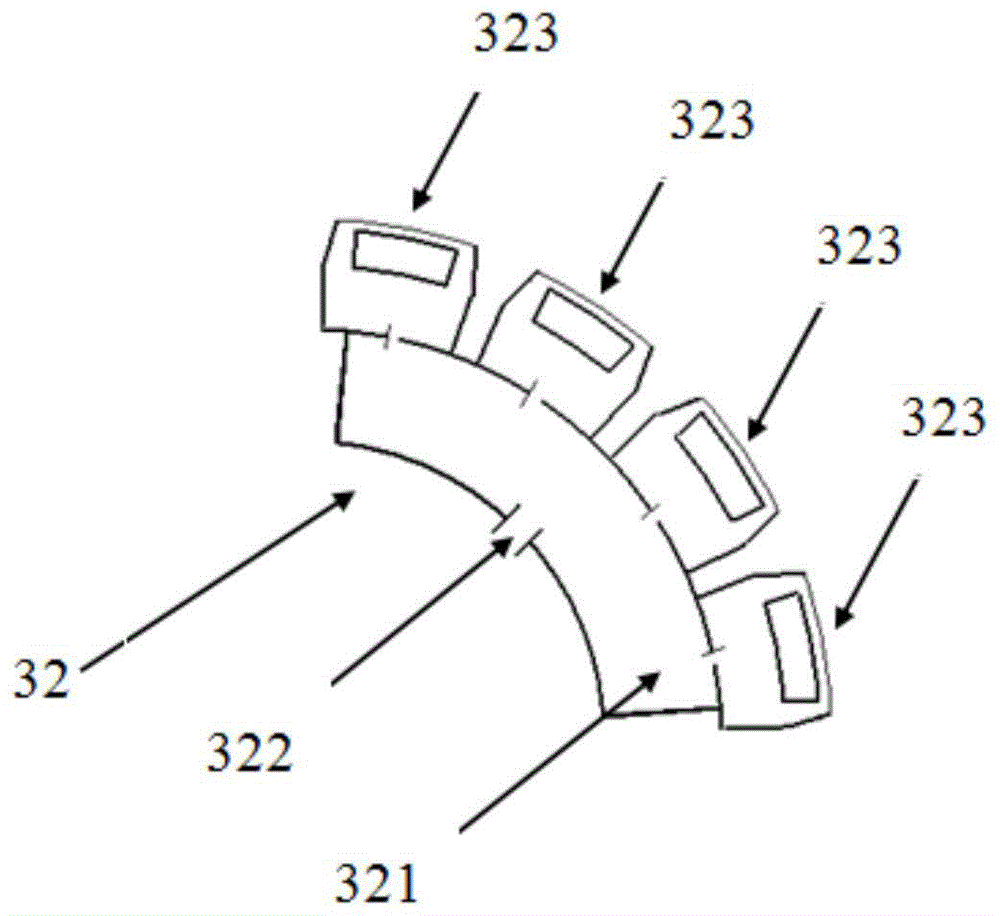

[0035] The structure of an air cushion furnace roll 3 provided by the present invention is as follows Figure 2~4 As shown, the roller sleeve 31 is provided with four arc-shaped air cushions 32 of the same shape. The four arc-shaped air cushions 32 are combined into a circle concentric with the roller sleeve 31, two arc-shaped air cushions 32 are on top, and two arc-shaped air cushions 32 are on top. The air cushion 32 is below, and the inlet pressure of each arc-shaped air cushion can be controlled separately. The arc-shaped air cushion 32 includes an air inlet chamber 321. The air inlet chamber 321 is sequentially arranged with an air inlet inner wall and an air inlet outer wall from the inside to the outside. There are air inlets 322 on the indoor wall, and four air-cushion modules 323 are evenly distributed on the outside of the air-intake outdoor wall. Of course, the number of air-cushion mold modules 323 can be increased or decreased according to specific needs. The air-cus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com