Coreless permanent magnet power generation and electric device

A technology of power generation device and electric device, which is applied in the direction of electromechanical device, electronic commutation motor control, magnetic attraction or thrust holding device, etc. It can solve the problems of complex structure and low power generation efficiency, achieve small size and reduce copper loss , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

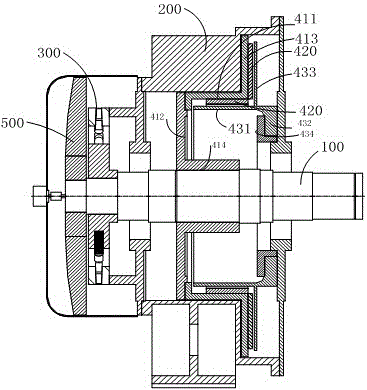

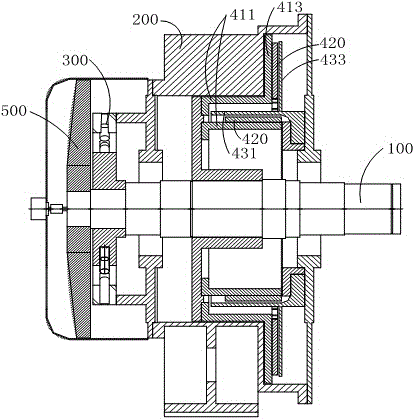

[0027] Such as Figure 1-3 As shown, this embodiment proposes a magnetic levitation coreless permanent magnet power generation device. The power generation device includes a shaft body 100, a casing 200 and a power generation assembly. The casing 200 and the shaft body 100 can rotate relative to each other. The casing 200 generally Installed on the shaft body 100 through bearings. During the relative rotation of the casing 200 and the shaft body 100 , the power generation component generates power.

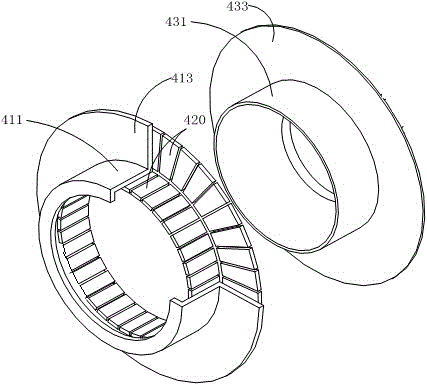

[0028] This embodiment focuses on explaining the structure of the power generation assembly:

[0029] The casing 200 of this embodiment is an outer stator, and the shaft body 100 is an inner rotor. The power generation assembly includes a rotor assembly and a stator assembly. Wherein, the rotor assembly includes a yoke and a magnet 420 install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com