Alloy welding wire

A technology of alloy welding wire and welding wire, applied in welding medium, welding equipment, metal processing equipment, etc., can solve problems affecting production efficiency, difficult to start arc, easy to break arc, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to enable those skilled in the art to better understand the solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings of the embodiments.

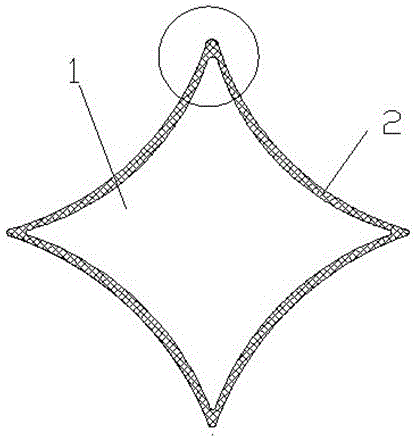

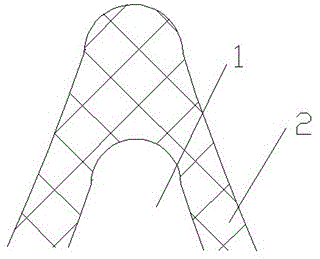

[0013] Such as figure 1 As shown, an alloy welding wire of the present invention includes a welding wire body 1 whose cross-section is quadrilateral, wherein the quadrilateral is formed by connecting four inwardly concave arcs end to end. By designing the cross-section of the welding wire as a quadrilateral with each side sunken inward, that is, a quadrilateral with sharp corners, the problem that the welding wire is easy to roll is effectively avoided. The probability of problems such as arc striking and arc breaking can ensure the welding effect very well. Preferably, such as figure 2 As shown,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap