Method for preparing oyster polysaccharide

A technology of oyster polysaccharide and oyster meat, applied in the field of preparation of oyster polysaccharide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] a. Add 5 L of water to 100g oyster meat and homogenate;

[0017] b. Heat at 70°C for 60 minutes, centrifuge at 5000rpm for 30 minutes, and take the supernatant;

[0018] c. Add the supernatant to the hydrophobic resin ME-1 column for chromatography, and elute with water, 5% ethanol by mass percentage and 15% ethanol by mass percentage, until the eluent does not contain sugar (phenol-sulfuric acid method) detection), to obtain water elution fraction, 5% ethanol elution fraction and 15% ethanol elution fraction;

[0019] d. Add 80% ethanol to the water-eluted fraction, 5% ethanol-eluted fraction and 15% ethanol-eluted fraction respectively to a saturated concentration to obtain precipitates respectively. The masses of the three precipitates are 4g, 5g and 11g respectively. g.

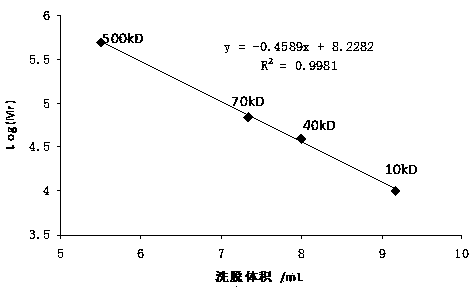

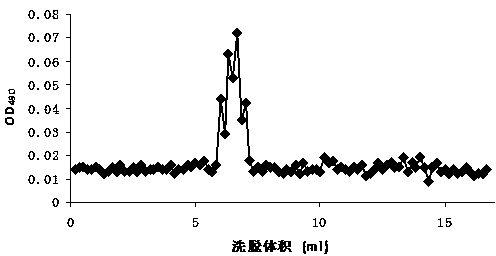

[0020] The obtained three precipitates were passed through TSK-gel G4000PW XL Column (7.8 mm × 30 cm), the determination curve is as follows figure 2 , 3 , 4 shown. According to ...

Embodiment 2

[0022] a. Add 2 L of water to 300g oyster meat and homogenate;

[0023] b. Heat at 80°C for 50 minutes, centrifuge at 10,000 rpm for 10 minutes, and take the supernatant;

[0024] c. Add the supernatant to the hydrophobic resin ME-1 column for chromatography, and elute with water, 5% ethanol by mass percentage and 15% ethanol by mass percentage, until the eluent does not contain sugar (phenol-sulfuric acid method) detection), to obtain water elution fraction, 5% ethanol elution fraction and 15% ethanol elution fraction;

[0025] d. Add 80% ethanol to the water elution fraction, 5% ethanol elution fraction and 15% ethanol elution fraction respectively to the saturated concentration to obtain precipitates respectively. The masses of the three kinds of precipitates are 11g, 15g and 30g respectively g.

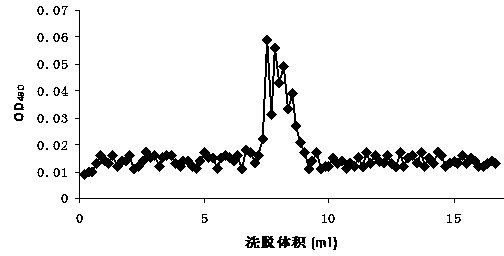

[0026] Same as Example 1, the three precipitates obtained were passed through TSK-gel G4000PW respectively XL Column (7.8 mm × 30 cm), determination curve. Accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com