Rail Lifting Device of Mobile Rail Flash Welding Machine

A flash welding machine and mobile technology, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems that the outer dimension of the welding machine does not meet the requirements of use, the rail welding operation cannot be performed, and the process of padding rollers is complicated, etc. The effect of restricting long rails, simple structure, and large rail lifting load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

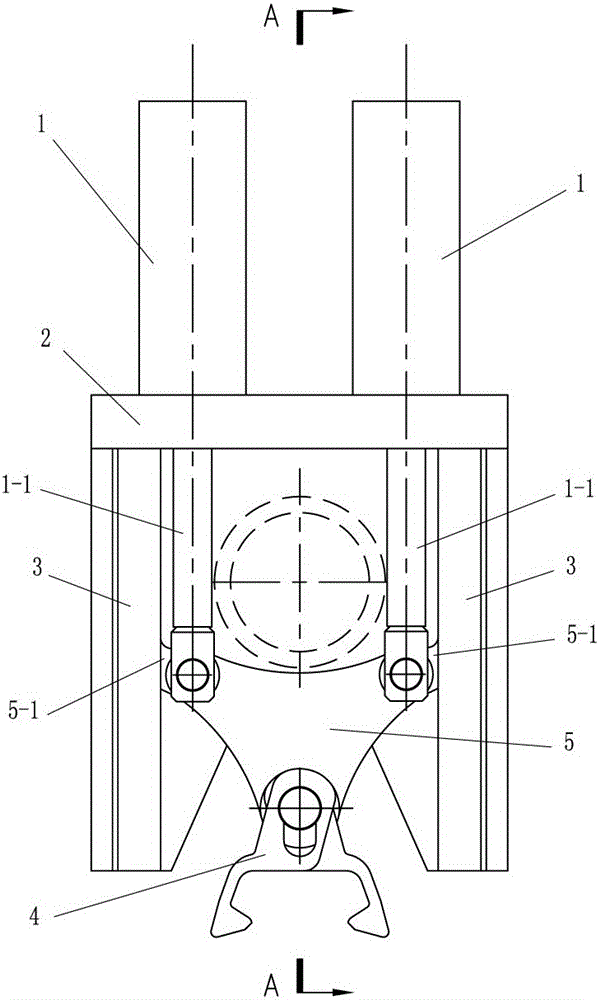

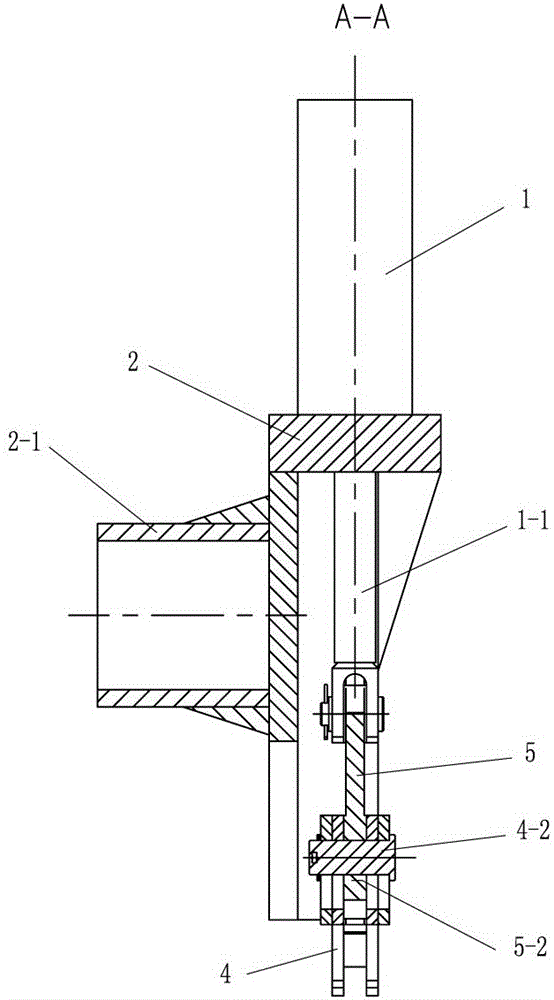

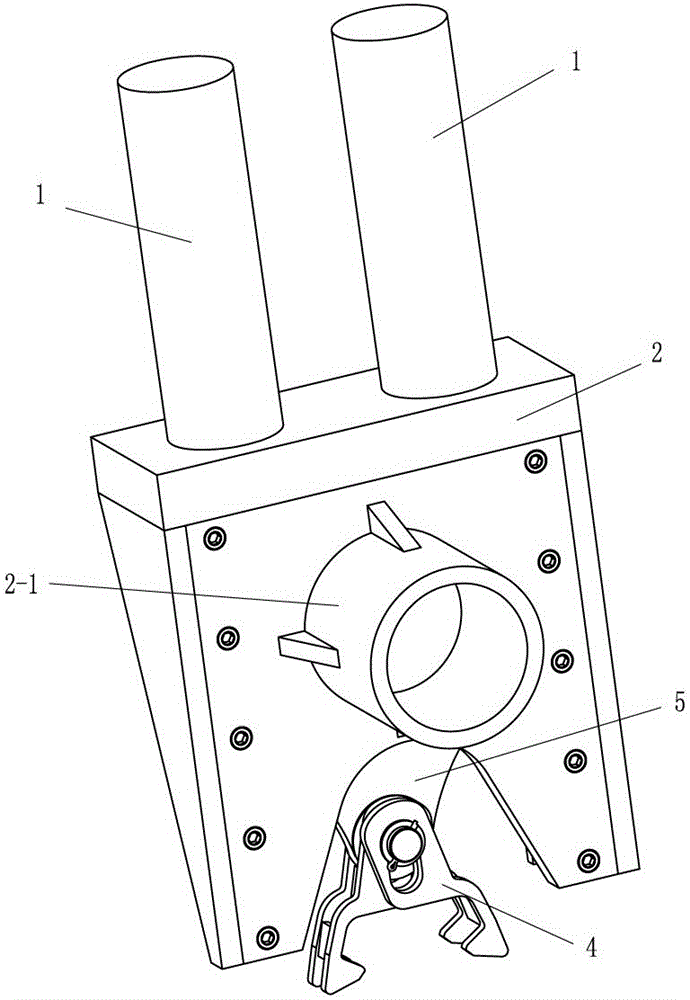

[0017] Such as figure 1 , 2 , 3, 4, and 5, the rail lifting device of a mobile rail flash welder of the present invention includes a clamp 4, and also includes a lifting cylinder 1, a mounting bracket 2, a guide rail 3 and a lifting member 5, and the lifting cylinder 1 is installed on the mounting bracket 2, the clamp 4 is connected with the piston rod 1-1 of the lifting cylinder 1 through the lifting piece 5, the guide rail 3 is installed on the mounting bracket 2, and the lifting piece 5 is slidingly matched with the guide rail 3.

[0018] Such as figure 1 , 2 , 4, the lift cylinder 1 has two, and the piston rods 1-1 of the two lift cylinders 1 are jointly connected to the upper end of the lift piece 5, and both sides of the lift piece 5 have sliding parts 5-1, and the lift piece 5 The lower end of the lower end is connected to the fixture 4, and both sides of the mounting bracket 2 are provided with guide rails 3, and the sliding part 5-1 of the lifting member 5 is slida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com