Hydraulic fracturing ground stress testing system for panoramic drill hole inspection instrument

A testing system and peeping instrument technology, which is applied in the direction of earthwork drilling and production, wellbore/well components, etc., can solve the problems of inability to peek at the drilling hole, hinder the detection effect of surrounding rock, and make it difficult to monitor the condition of surrounding rock, so as to achieve convenient use , The effect of the test results is clear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

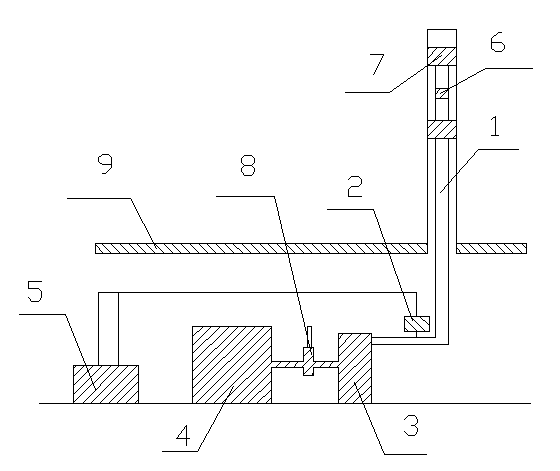

[0010] Such as figure 1 As shown, a hydraulic fracturing ground stress testing system of a panoramic drilling peeping instrument includes a high-pressure pipe 1, a pressure sensor 2, an accumulator 3, a high-pressure oil pump 4 and a data acquisition instrument 5, and one end of the high-pressure pipe 1 A water injection hole 6 is provided, the upper end of the water injection hole 6 is provided with a packer 7, the high-pressure pipe 1 is respectively connected with the accumulator 3 and the pressure sensor 2, the accumulator 3 is connected with the high-pressure oil pump 4, and the A flow meter 8 is provided at the place where the accumulator 3 is connected to the high-pressure oil pump 4 , and the pressure sensor 2 is connected to the data acquisition instrument 5 .

[0011] The two sides of the high-pressure pipe 1 are respectively provided with roadway roofs 9 .

[0012] The working principle of the present invention: firstly, in the drilled hole, the rubber packer 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com