Electromagnetic heating insertion-type plastic pipeline fusing and adhering technology

A plastic pipe and plug-in technology, which is applied in the direction of pipe connection arrangement, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve problems such as difficulty in mastering the amount of adhesive used, damage to the physical and mental health of construction workers, and quality problems with adhesives, etc., to achieve Convenient construction, not easy to deform and damage, prevent corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

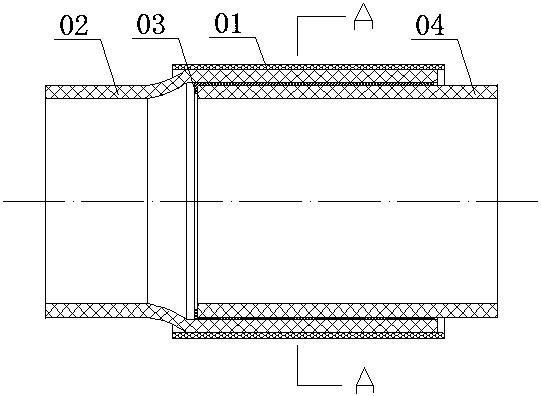

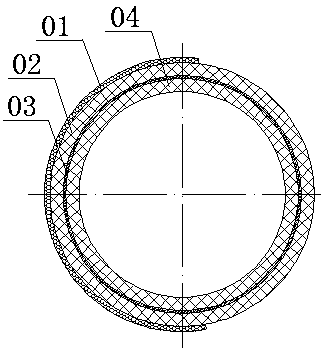

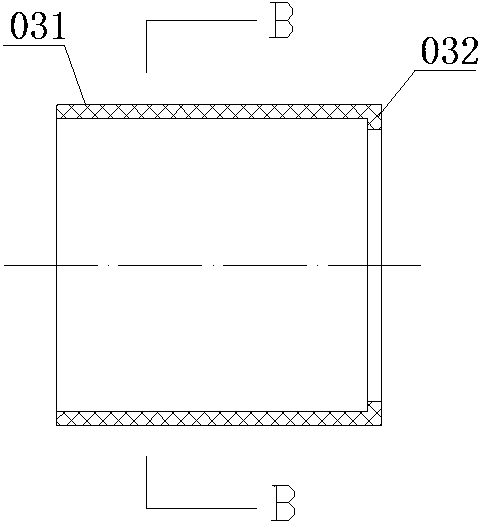

[0020] As shown in the figure, the hot-melt adhesive film (03) is a cylindrical structure with a shrinking mesh opening, and is a medium material used for bonding of plug-in plastic pipe joints.

[0021] The magnetic material net (12) is a network structure made of environmentally friendly and non-toxic magnetic conductive metal materials; the hot-melt material (11) is a solid and hot-melt material at normal temperature, which can be Plastic, adhesive or a mixture of plastic and adhesive; the shrinkage net (032) is a non-elastic annular body with sufficient strength, bound together with one end of the hot-melt adhesive film (03).

[0022] Fill the mesh holes of the magnetic permeable material net (12) with hot-melt material (11), or completely wrap the magnetic permeable material net (12) to make a hot-melt adhesive film (03), hot-melt adhesive The film (03) has a certain stretchability, so that it can be tightly sleeved on the straight cannula (04) of the plastic pipe joint. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com