Multifunctional LED (light emitting diode) lamp cap connection mechanism

A technology of LED lamp holders and connecting mechanisms, which is applied in the direction of lighting devices, light sources, and parts of lighting devices, can solve the problems of shortened life, increased use cost, and easy burnout, and achieves reduced manufacturing costs, improved manufacturing efficiency, and better use Effect of life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

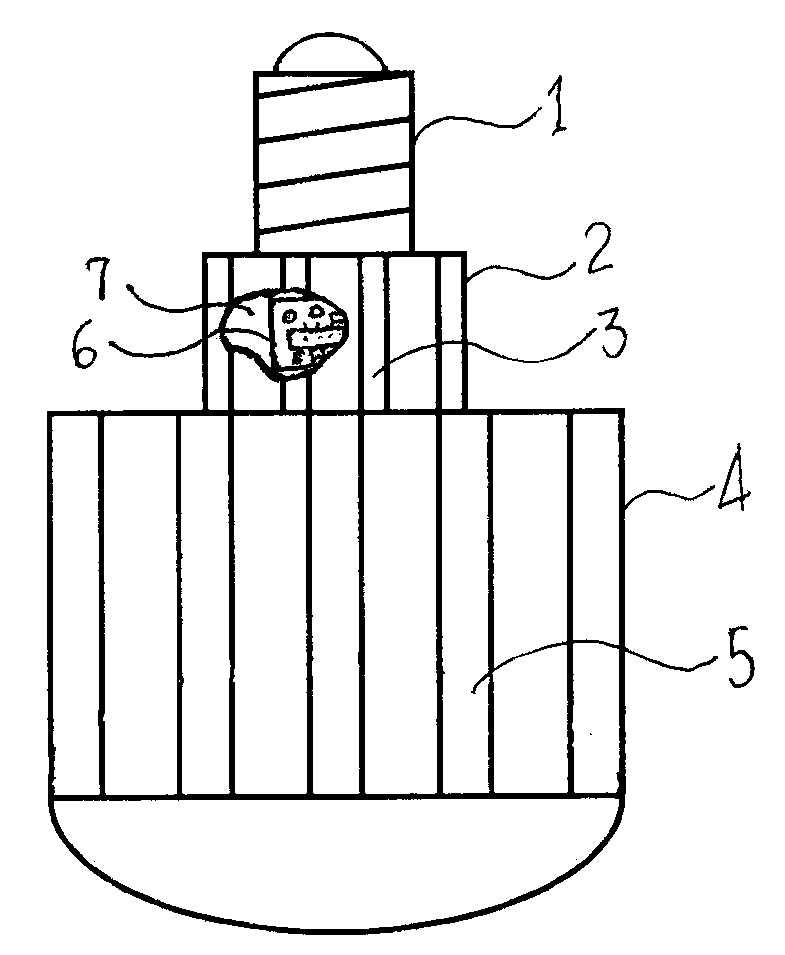

[0015] As shown in the figure, the multifunctional LED lamp cap connection mechanism of the present invention includes a lamp cap 1, a heat dissipation mechanism 4, and a lamp cap connection mechanism 2 connected with the lamp cap 1 and the heat dissipation mechanism 4 respectively. The connection mechanism 2 has a component cavity 7 communicating with the heat dissipation port 3, and the drive power component 6 of the LED lamp is installed in the component cavity 7. There is a transparent air transverse direction between the cooling fins of the heat dissipation mechanism 4, which can allow the air to traverse the convection. Convection channel 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com