Automatic rod connecting mechanism for garbage cracking furnace

A rod mechanism and cracking furnace technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of high labor intensity, low efficiency of loading and unloading rods, and reducing the efficiency of garbage cracking furnaces to deal with garbage, etc., to reduce labor intensity and improve. The effect of waste disposal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing.

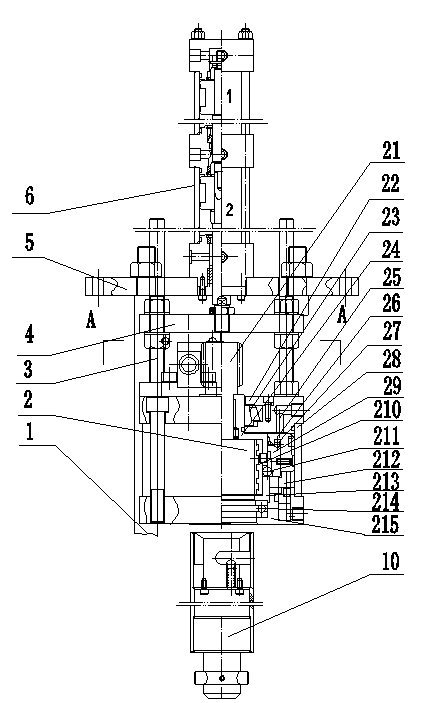

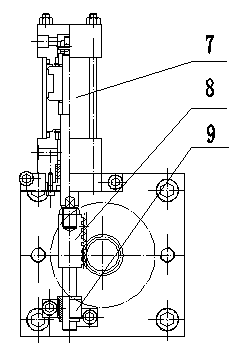

[0010] In the figure: column 1, post water tank 2, guide post 3, guide post connecting plate 4, post mechanism mounting plate 5, post feed water tank 6, post rotating water tank 7, rack 8, rack positioning Seat 9, pressure rod 10, gear 21, bearing cover 22, bearing 23, brake shoe positioning seat 24, upper end cover 25, piston I26, plane bearing 27, cylinder body 28, inner cone pressure sleeve 29, brake shoe 210, steel ball 211, piston II212, plane bearing cover 213, plane bearing 214, lower end cover 215.

[0011] as attached figure 1 , attached figure 2 As shown, the automatic connecting rod mechanism of the garbage cracking furnace of the present invention includes a column 1, a connecting rod water tank 2, a guide post 3, a guide post connecting plate 4, a connecting rod mechanism mounting plate 5, a connecting rod feeding water tank 6, and a connecting rod rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com