Humidity sensor based on multimode fiber core and fiber grating and preparation method of humidity sensor

A humidity sensor and fiber grating technology, applied in the field of fiber grating sensors, can solve the problems of improving humidity sensitivity, increasing manufacturing cost and packaging difficulty, and complex manufacturing process of coated fiber grating humidity sensor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

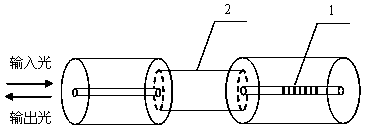

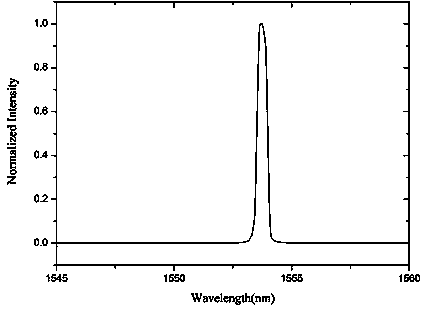

[0020] Such as figure 1 As shown, the fiber Bragg grating 1 we choose is the fiber Bragg grating 1 written on the Corning SM28 fiber. The period of the fiber Bragg grating 1 is 400um, and the central wavelength of the reflection peak is 1553.460nm. The transmission spectrum of the fiber Bragg grating 1 is as follows: figure 2 , where the ordinate is the normalized intensity, and the abscissa is the wavelength.

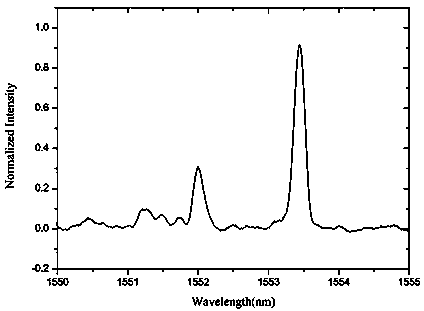

[0021] Strip the coating from a 35cm-long multimode optical fiber (S105 / 125), wipe it clean with alcohol, and put it in hydrofluoric acid with a concentration of 45% to remove the cladding of the optical fiber. Multimode fiber cores with different diameters can be obtained by controlling the etching time. After 10 minutes of corrosion, the multimode fiber core 2 is taken out and washed repeatedly with distilled water to remove residu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com