Aerosol different-particle-size sample injection system

A sampling system, aerosol technology, applied in the direction of sampling device, air quality improvement, test sample preparation, etc., can solve systematic deviation, can not guarantee the consistency of cut particle size of dry state particles, affect PM mass concentration and The accuracy of chemical composition measurement cuts the uniformity of particle size and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with specific embodiments.

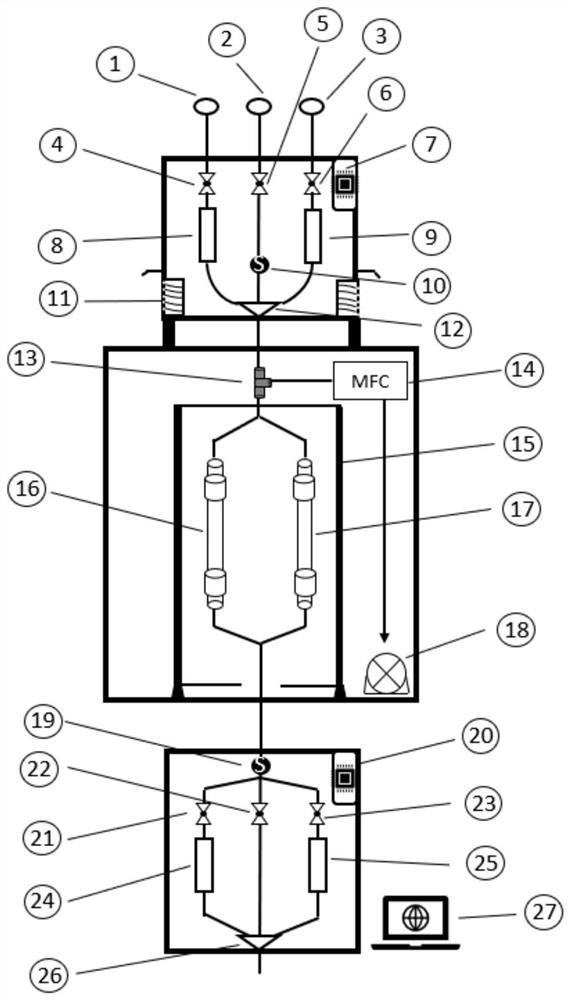

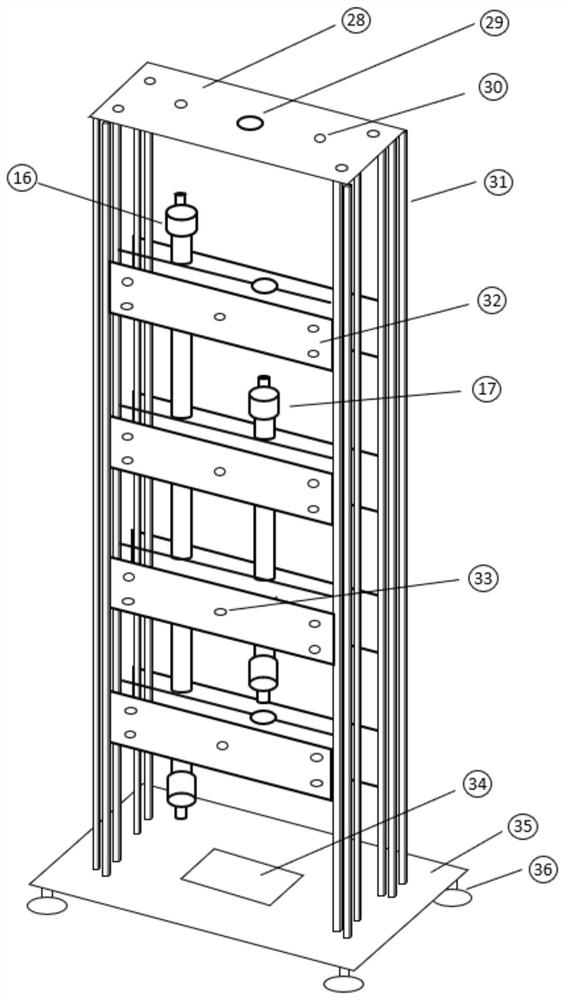

[0023]An aerosol particle size sampling system, comprising a multi-channel air inlet switching unit, a primary cutting unit, a drying unit, a flow supplementary unit, a secondary multi-channel switching unit, a secondary cutting unit and a computer control module; The air switching unit is connected with the primary cutting unit to cut the ambient air in different ways. The multi-channel intake switching unit is connected with the flow supplementary unit to supplement the flow of the cutting sampling gas. The multi-channel intake switching unit is connected with the drying unit. It is used to dry the humidity of the sampling gas; the drying unit is connected with the secondary multi-channel switching unit to divide the dried sampling gas; the secondary multi-channel switching unit and the secondary cutting unit are connected to separate the dried sampling gas. Cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com