A traction motor junction box suitable for high voltage levels and its manufacturing method

A traction motor and manufacturing method technology, applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve problems such as unreliable insulation of motor junction boxes, and achieve stable insulation performance, ensure insulation reliability, and facilitate sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

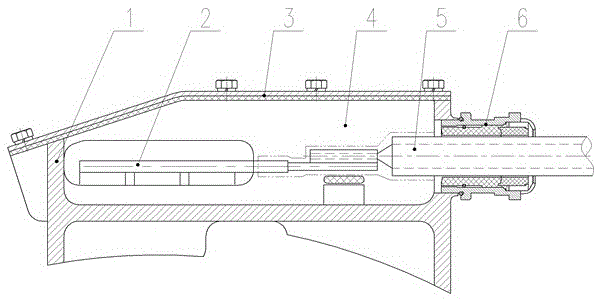

[0026] Such as figure 1 As shown, the traction motor junction box suitable for high voltage levels includes a box body 1 and a junction box cover plate 3 covered on the box body, three-phase lead wires 2, three-phase cables 5 and potting glue 4, The three-phase lead wires and the three-phase cables all enter the box body from outside the box body and are connected in the box body, and the potting glue is potted inside the box body. The box body is provided with feet at the bottom of the box body, three-phase lead-out wire outlet holes for three-phase lead-out wires to pass through, three-phase cable wire outlet holes for three-phase cable wires to pass through, and three-phase cable outlet holes for tightening three-phase cables. Thread tightening member 6.

[0027] The internal wiring of the motor junction box adopts a welding structure. After the welding is completed, it is insulated, and then the junction box is potted as a whole to solve the problem of reliable sealing an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com