Electro-static discharge device

An anti-static, mat technology, applied in the direction of static electricity, electrotherapy, electrical components, etc., can solve the problems of undetectable, component damage, failure and damage, called hard breakdown components, etc., to achieve the effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

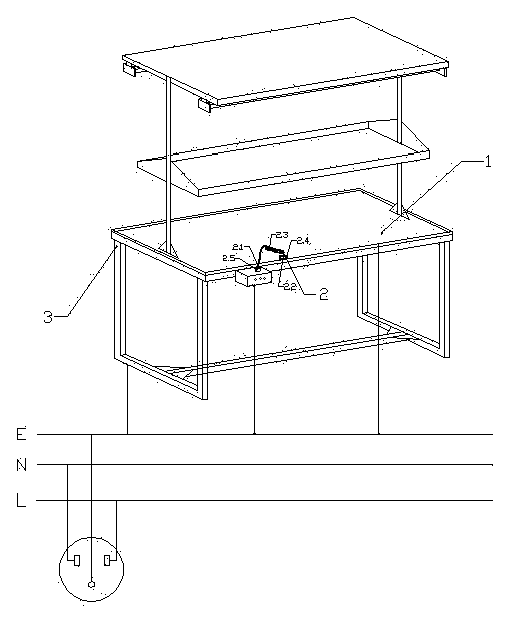

[0010] The present invention will be further described below in conjunction with accompanying drawing.

[0011] With reference to accompanying drawing, a kind of antistatic device comprises a workbench 3, the ESD mat 1 laid on the workbench and the antistatic ESD wristband 2 installed on workbench 3 one side; By wearing the ESD wristband 2 to the operator Grounding, ESD mat 1 grounding on the work surface, and direct grounding of metal objects such as machines and workbenches to eliminate static electricity.

[0012] The ESD wrist strap 2 worn by the operator includes a base belt 2.4, a grounding body 2.5, an upper fastener on the grounding body, a lower fastener 2.2 on the base belt 2.4, and a spring 2.3 between the upper fastener 2.1 and the lower fastener 2.2; The ESD mat 1 has a two-layer structure, the surface layer is a static dissipative layer, and the bottom layer is a conductive layer.

[0013] The upper fastener 2.1, the lower fastener 2.2 and the spring 2.3 are all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com