Rock-fill concrete construction method used for wave wall foundation platform

A technology of rockfill concrete and foundation platform, which is applied to bank walls, embankments, breakwaters, etc., can solve the problems of complex process, large human interference, and difficult quality assurance, and achieves good volume stability, simple construction technology, and mechanized operation. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

[0028] Such as Figure 7 Shown, a kind of rockfill concrete construction method that is used for wave wall foundation platform, it comprises the following steps:

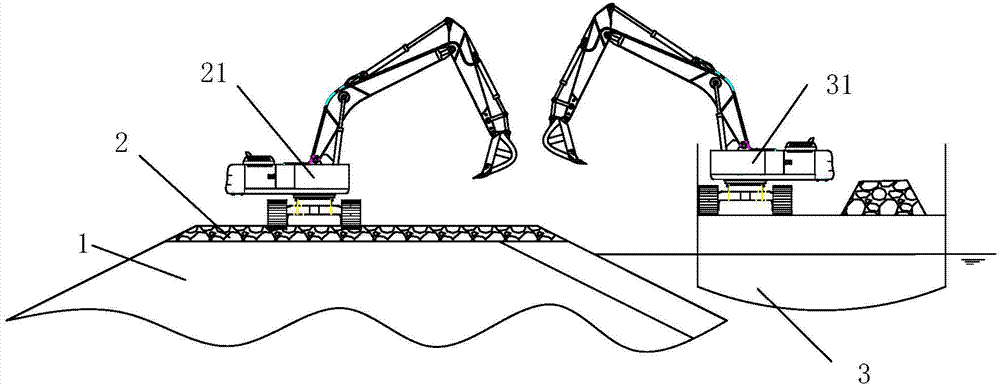

[0029] Step 1: If figure 1 As shown, a grout-stop layer 2 is laid on the upper surface of the dike body 1, and the grout-stop layer adopts a crushed stone cushion with a particle size of 10-100 mm. On the other hand, laying is carried out when the seawater ebbs, and after the laying is completed, the excavator 21 is used for rolling and compacting.

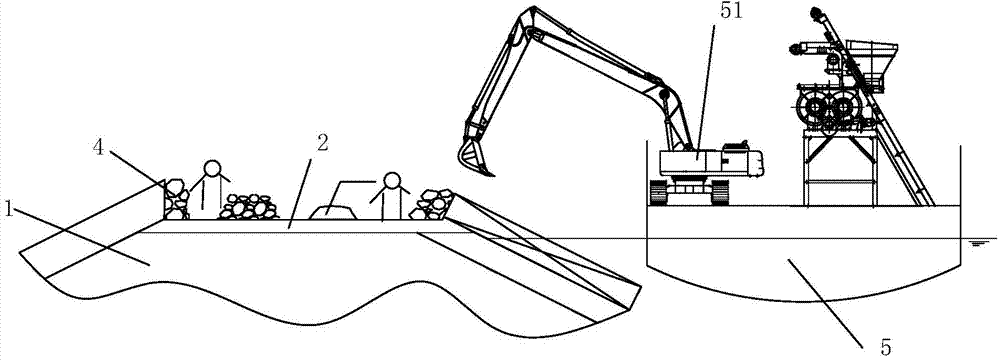

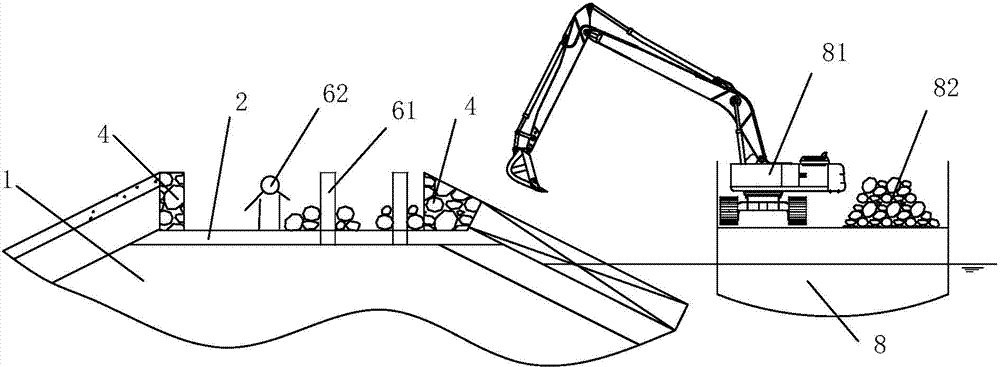

[0030] Step 2: If figure 2 As shown, a formwork 4 is built on both sides of the grout-stopping layer 2; the formwork 4 is made of artificial mortar with block stones with a width of 50 cm, and the required mortar can be produced by the mixing ship 5, and the length of the mixing ship 5 Arm excava...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com